Gorman-Rupp Pumps PA4A60C-B-E30 575/3 1482736 and up User Manual

Page 46

OM−06440

PA SERIES

MAINTENANCE & REPAIR

PAGE E − 19

gency, carefully wash all metallic parts in fresh

cleaning solvent and allow to dry thoroughly.

Handle the seal parts with extreme care to prevent

damage. Be careful not to contaminate precision

finished faces; even fingerprints on the faces can

shorten seal life. If necessary, clean the faces with a

non-oil based solvent and a clean, lint-free tissue.

Wipe lightly in a concentric pattern to avoid

scratching the faces.

Inspect the seal components for wear, scoring,

grooves, and other damage that might cause leak-

age. Clean and polish the shaft sleeve, or replace it

if there are nicks or cuts on either end. If any com-

ponents are worn, replace the complete seal;

never mix old and new seal parts.

If a replacement seal is being used, remove it from

the container and inspect the precision finished

faces to ensure that they are free of any foreign

matter.

To ease installation of the seal, lubricate the shaft

sleeve O-ring and the external stationary seat O-

ring with a very small amount of light lubricating oil.

See Figure 9 for seal part identification.

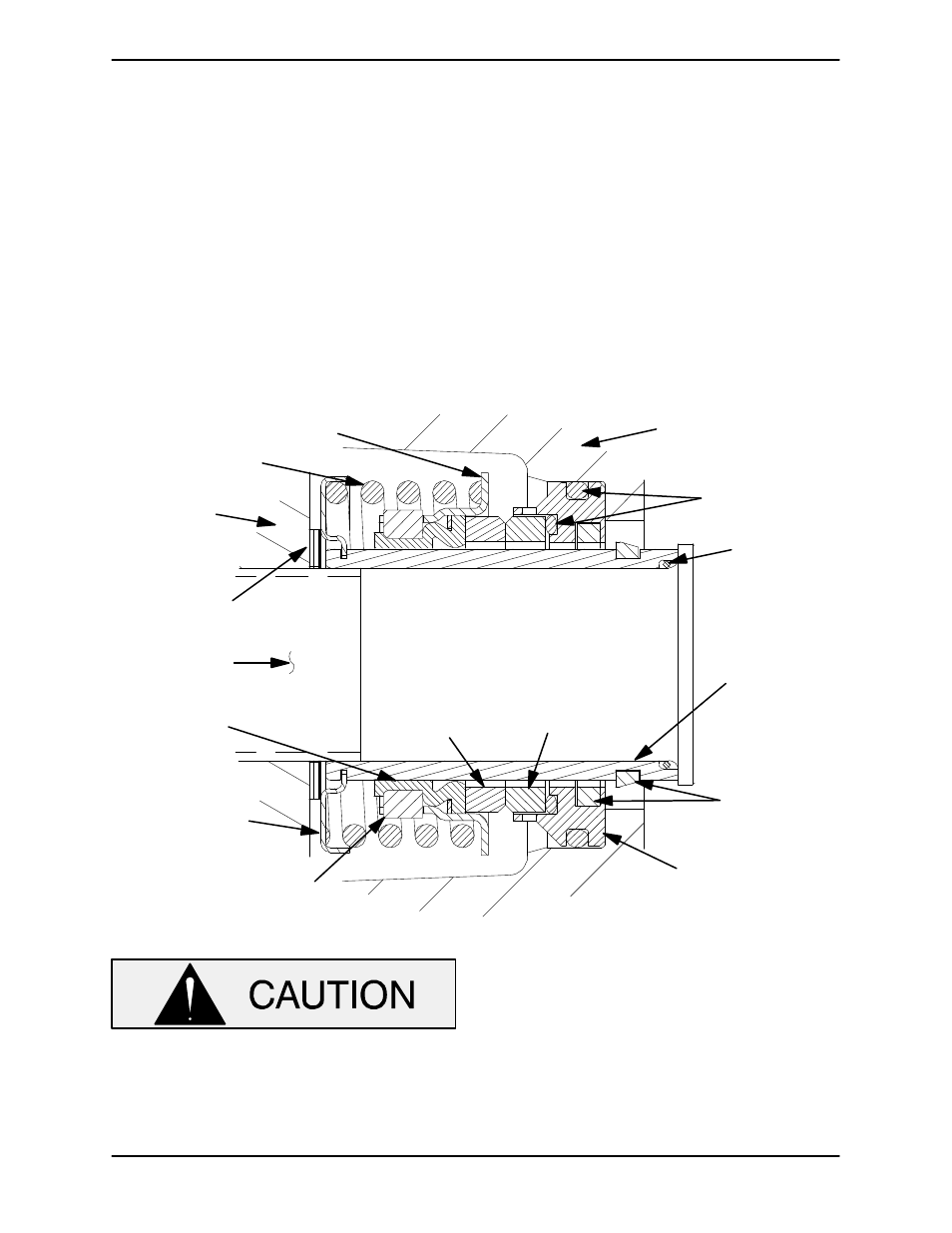

SEAL PLATE

O-RINGS

IMPELLER

SHAFT

STATIONARY

SEAT

STATIONARY

ELEMENT

ROTATING

ELEMENT

DRIVE BAND

BELLOWS

IMPELLER

SHIMS

IMPELLER

SPRING

RETAINER

INTEGRAL

SHAFT

SLEEVE

SLEEVE

O-RING

SPRING

CENTERING

WASHER

SHEAR

RING

(SHEARED)

Figure 9. Seal Assembly

This seal is not designed for operation at

temperatures above 160

_F (71_C). Do not

use at higher operating temperatures.

If the seal plate was removed, install the seal plate

gasket (5). Position the seal plate over the shaft

and secure it to the bearing housing with the hard-

ware (7 and 8).

To prevent damaging the shaft sleeve O-ring (26)

on the shaft threads, cover the threads with electri-

cal or duct tape. Slide the O-ring over the shaft until

it seats against the shaft shoulder. Remove the

tape covering the threads. Check to ensure that

the shaft threads are free of any tape residue and