Gorman-Rupp Pumps PA6C60-C4.4T 1404116 and up User Manual

Page 37

OM-06171

PA SERIES

MAINTENANCE & REPAIR

PAGE E - 17

Draining Oil From Seal Cavity

(Figure 5)

If any further disassembly is to be performed on the

pump, the seal oil cavity must be drained to pre

vent the oil in the seal cavity from escaping as the

pump casing is removed.

Position a clean container (3 gallons [11,4 liters]

minimum capacity) under the seal cavity drain plug

(10B). Remove the plug and drain the oil from the

seal cavity into the container. For shorter drain

time, remove the vented plug (14). Clean and rein

stall the drain plug and vent plug. Inspect the oil for

water, dirt or a cloudy condition which could indi

cate seal failure.

Loosening Impeller

(Figure 5)

With the pump end separated from the engine,

wedge a block of wood between the vanes of the

impeller and the pump casing to prevent rotation.

Remove the impeller capscrew and washer (26

and 27).

Install the shaft key (22) in the shaft keyway. Install

a lathe dog on the drive end of the shaft (23) with

the “V” notch positioned over the shaft key.

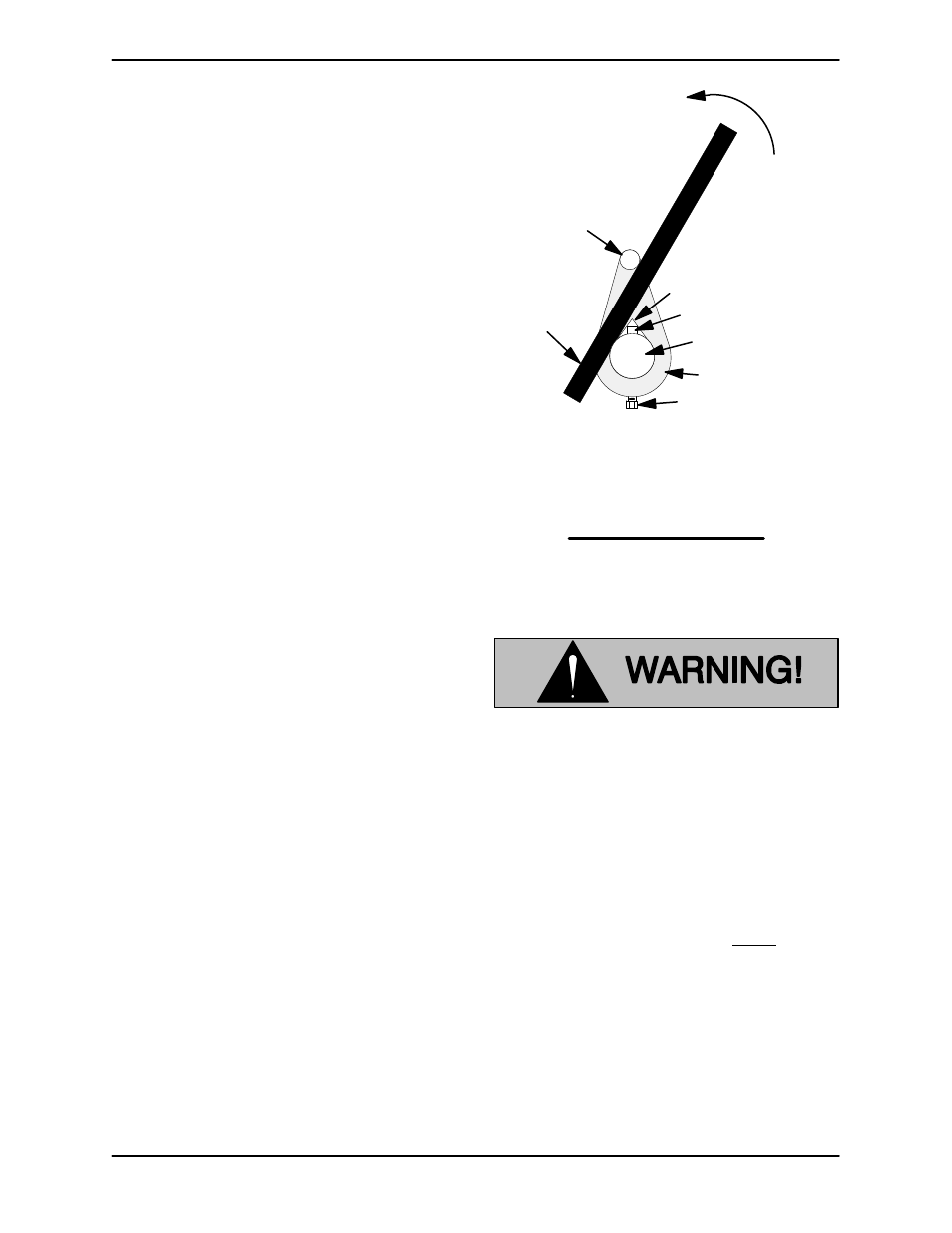

With the impeller rotation still blocked, see Figure 9

and use a long piece of heavy bar stock to pry

against the arm of the lathe dog in a counterclock

wise direction (when facing the drive end of the

shaft). Use caution not to damage the shaft or key

way. When the impeller breaks loose, remove the

lathe dog, key and wood block.

Turn

Counterclockwise

Lathe Dog Arm

“V” Notch

Shaft Key

Impeller Shaft

Lathe Dog

Setscrew

Heavy

Bar Stock

Figure 9. Loosening Impeller

NOTE

Do not remove the impeller until the rotating assem

bly has been removed from the pump casing.

Pump Casing Removal

(Figure 4)

Death or serious personal injury and

damage to the pump or components

can occur if proper lifting procedures

are not observed. Make certain that

hoists, chains, slings or cables are in

good working condition and of suffi

cient capacity and that they are posi

tioned so that loads will be balanced

and the pump or components will not be

damaged when lifting. Suction and dis

charge hoses and piping must be re

moved from the pump before lifting. Lift

the pump or component only as high as

necessary and keep personnel away

from suspended objects.

Support the pump casing using a suitable hoist

and sling, and remove the hardware (18 and 19).

Install four 1/2-13 UNC x 2‐inch long jacking

screws in the tapped holes in the bearing housing

(6, Figure 5). Tighten the jacking screws in an alter