Gorman-Rupp Pumps PA6F60-4045T 1521221 and up User Manual

Page 42

PA SERIES

OM-06189

MAINTENANCE & REPAIR

PAGE E - 20

peller lock screw). Make sure the seal spring

seats squarely over the step on the back side of the

impeller.

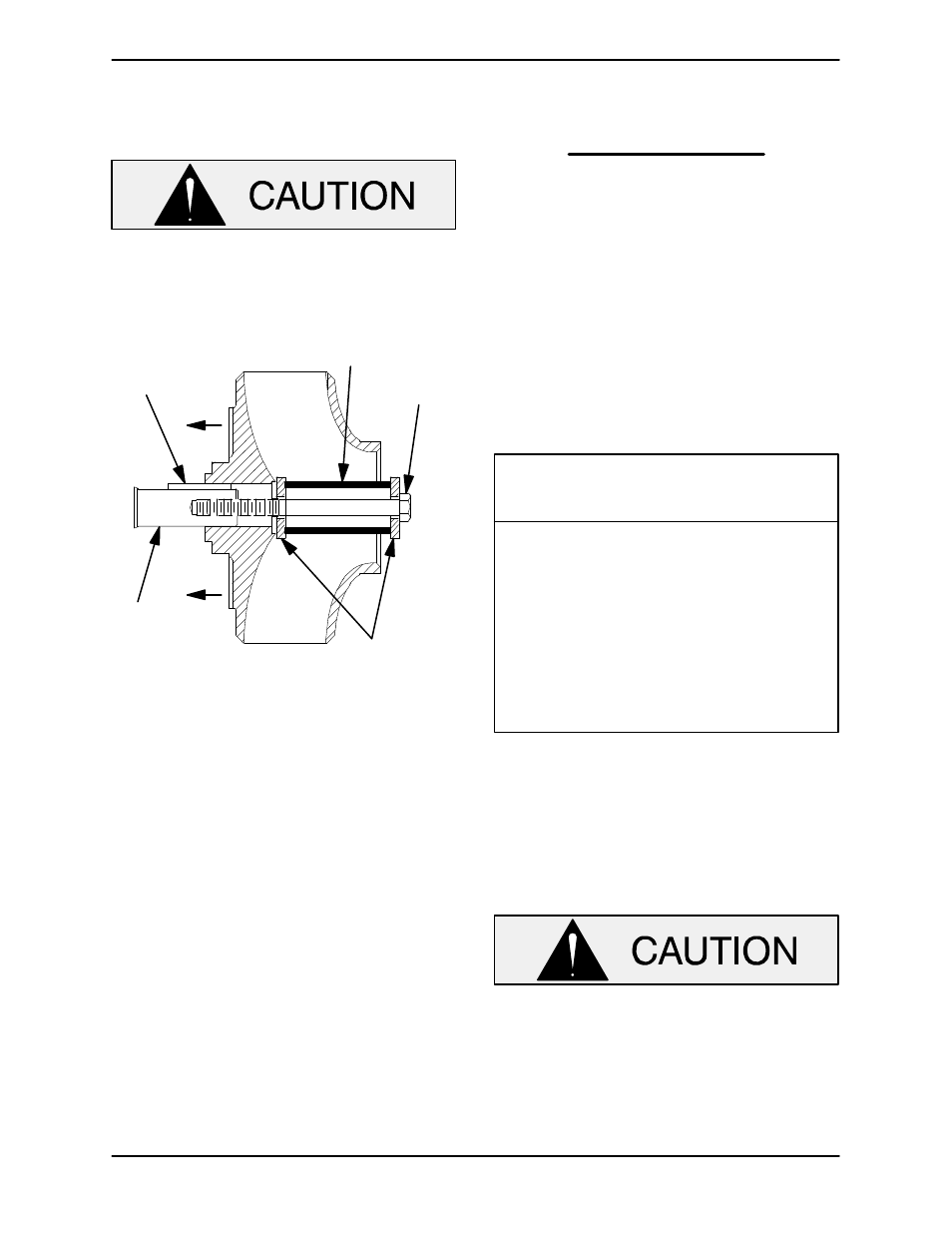

When installing the impeller, the capscrew

must be long enough to enter the shaft at

least eight full threads. Otherwise, damage

to the shaft threads may occur.

Shaft

Key

Pipe

Washers

Long

Capscrew

Figure 9. Installing Impeller

A clearance of approximately .030 inch (0,76 mm)

between the impeller and the back plate is recom

mended for maximum pump efficiency. Measure

this clearance, and add or remove impeller adjust

ing shims as required.

The pump casing must be installed in order to

properly torque the impeller lock screw (50). After

the impeller clearance has been set, install the

pump casing as described below, then proceed as

follows to install the impeller washer (51) and lock

screw.

NOTE

To ensure proper torquing of the impeller lock

screw, make sure the tapped hole in the impeller,

the impeller washer and the impeller lock screw are

clean and dry (it is not necessary to remove the pro

tective coating from the capscrew). It is recom

mended that a new impeller lock screw be used

whenever the impeller is removed. To ensure the

proper lock screw material and specifications, use

only genuine Gorman‐Rupp replacement parts.

With the pump casing installed, coat the threads of

a new impeller lock screw with “Loctite Threadlock

er No. 262” or equivalent compound, and install

the impeller washer and lock screw. Immobilize the

impeller by inserting a wood block through the dis

charge opening or cleanout cover opening as de

scribed in Pump Casing And Wear Ring Remov

al. With the impeller immobilized, torque the impel

ler lock screw to the specifications shown in Table

E-1.

Table E-1. Impeller Lock Screw Torque Values

Screw Size

Torque

(UNC)

Ft. Lbs. (M. Kg.)

.38-16

20 (2,8)

.50-13

40 (5,5)

.62-11

90 (12,4)

.75-10

135 (18,7)

1.00-8

265 (36,6)

1.12-7

360 (49,8)

1.25-7

510 (70,5)

1.50-6

875 (121,0)

Wear Ring And Pump Casing Installation

(Figure 5)

If the wear ring (49) was removed, chill the wear

ring by refrigeration and press it into the volute

bore until fully seated.

The wear ring must seat squarely in the

pump casing; otherwise binding and/or

excessive wear will occur.

Install the casing gasket (5). Use a suitable hoist

and sling to position the casing over the impeller,

and secure it to the back plate with the hardware

(42, 43 and 44).