Gorman-Rupp Pumps PAH3B60-4045H 1493144 and up User Manual

Page 46

OM-06474

PAH SERIES

MAINTENANCE & REPAIR

PAGE E - 23

Seal Reassembly and Installation

(Figures 6 and 10)

Most cleaning solvents are toxic and

flammable. Use them only in a well ven

tilated area free from excessive heat,

sparks, and flame. Read and follow all

precautions printed on solvent contain

ers.

Clean the seal cavity and shaft with a cloth soaked

in fresh cleaning solvent. Inspect the stationary

seat bore in the seal plate for dirt, nicks and burrs,

and remove any that exist. The stationary seat bore

must be completely clean before installing the

seal.

A new seal assembly should be installed

any time the old seal is removed from the

pump. Wear patterns on the finished faces

cannot be realigned during reassembly.

Reusing an old seal could result in prema

ture failure.

To ease installation of the seal, lubricate the shaft

sleeve O‐ring and the stationary element O‐ring

with a very small amount of light lubricating oil.

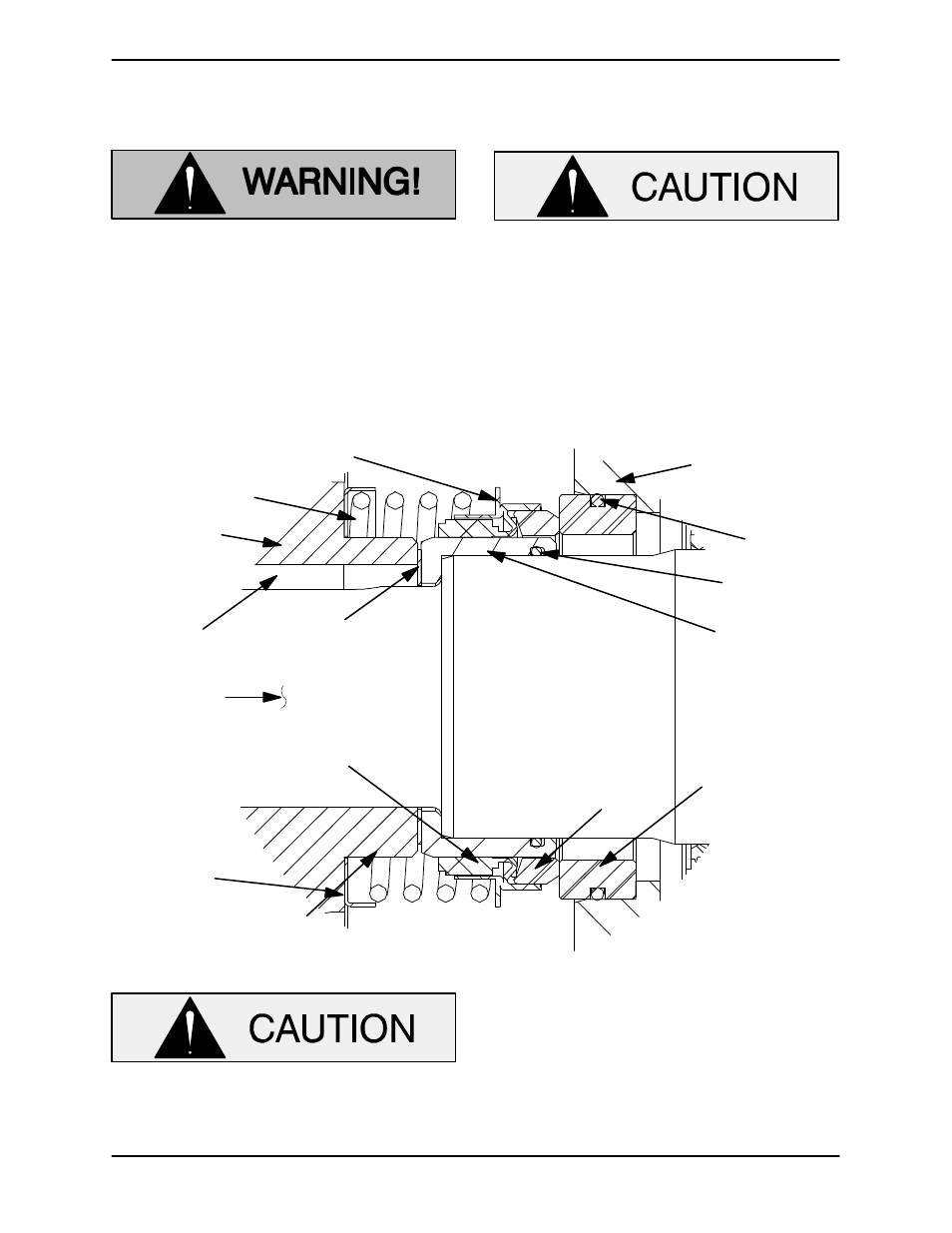

See Figure 10 for seal part identification.

SEAL PLATE

O‐RING

IMPELLER

SHAFT

STATIONARY

ELEMENT

ROTATING

ELEMENT

BELLOWS

IMPELLER

SHIMS

IMPELLER

SPRING

RETAINER

SHAFT

SLEEVE

SLEEVE

O‐RING

SPRING

CENTERING

WASHER

SHAFT

KEY

Figure 10. Seal Assembly

This seal is not designed for operation at

temperatures above 160

_

F (71

_

C). Do not

use at higher operating temperatures.

If the seal plate was removed, install the seal plate

gasket (14). Position the seal plate over the shaft

and secure it to the pedestal with the hardware (16

and 17).

Press the stationary element and its O‐ring into the

seal plate until fully seated in the seal plate bore. A

push tube cut from a length of plastic pipe would