Gorman-Rupp Pumps 3D-B 883512 and up User Manual

Page 17

D SERIES

OM−01490

MAINTENANCE & REPAIR

PAGE E − 1

PUMP MAINTENANCE AND REPAIR - SECTION E

MAINTENANCE AND REPAIR OF THE WEARING PARTS OF THE PUMP WILL MAINTAIN PEAK

OPERATING PERFORMANCE.

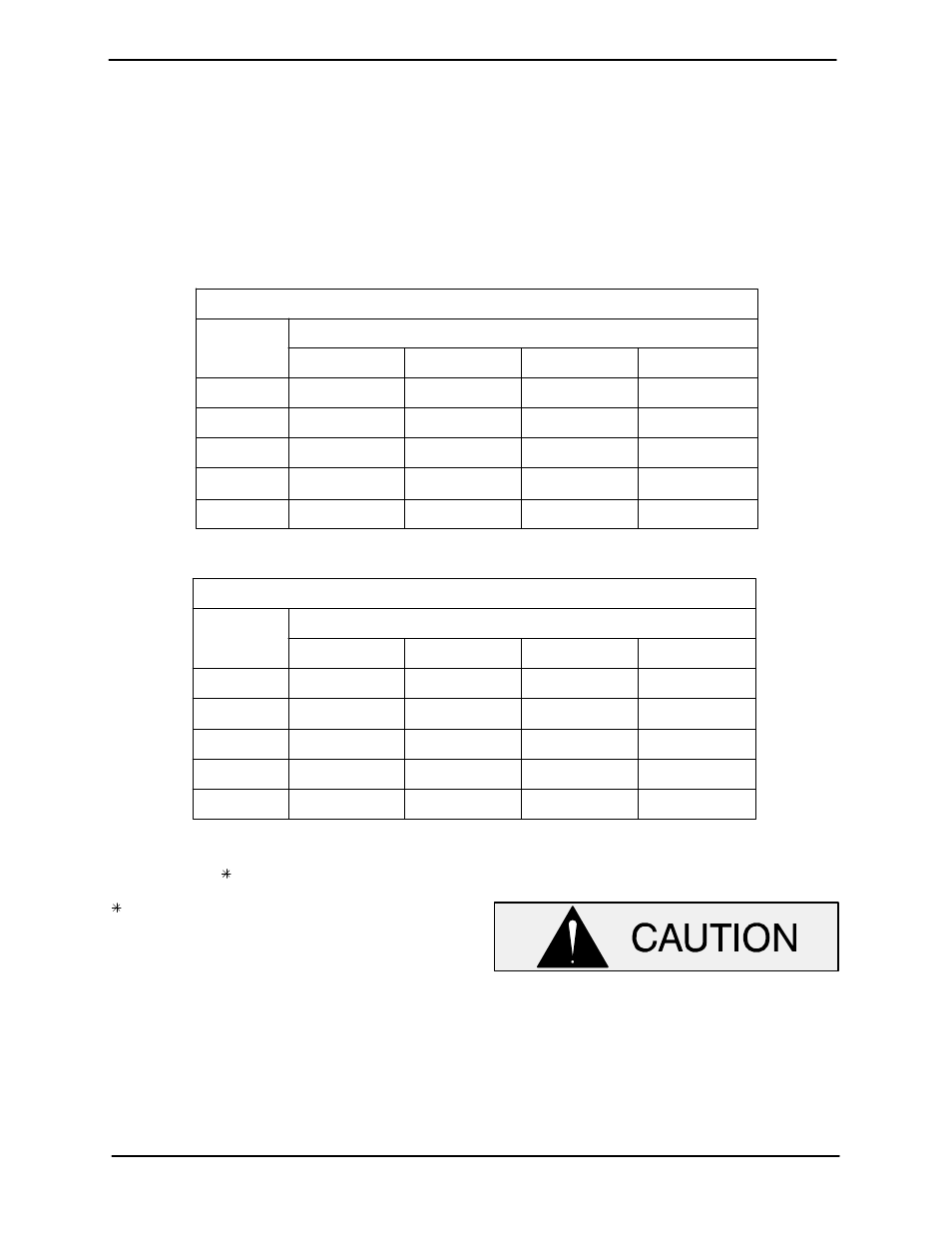

IN GALLONS PER MINUTE AT 60 STROKES PER MINUTE

STATIC

LIFT

IN FEET

STATIC DISCHARGE HEAD IN FEET

5

10

15

20

5

78

67

66

68

10

73

64

66

62

59

64

60

68

15

20

64

59

65

59

56

60

56

56

25

IN LITERS PER MINUTE AT 60 STROKES PER MINUTE

STATIC DISCHARGE HEAD IN METERS

STATIC

LIFT

IN METERS

1,5

3,0

4,6

6,1

1,5

295,2

253,6

249,8

257,4

3,0

276,3

242,2

249,8

234,7

4,6

257,4

227,1

242,2

223,3

6,1

242,2

223,3

246,0

223,3

7,6

212,0

212,0

227,1

212,0

STANDARD PERFORMANCE TEST DATA FOR PUMP MODEL 3D-B

Based on 70_ F (21_ C) clear water at sea level

with minimum suction lift, using 3 inch (7,62 cm)

suction hose and 4 inch (10,16 cm) non-collapsible

discharge hose. Since pump installations are sel-

dom identical, your performance may be different

due to such factors as viscosity, specific gravity,

elevation, temperature, and impeller trim.

If your pump serial number is followed by an N",

your pump is NOT a standard production model.

Contact the Gorman-Rupp Company to verify per-

formance or part numbers.

The pump end is designed to operate at

approximately 60 cycles per minute

through a gearbox with a 30.36:1 ratio at a

maximum input speed on 1750 RPM. Make

certain that input speed does not exceed

this RPM. Operation at higher RPM can

cause pump components to be damaged

or destroyed.