Gorman-Rupp Pumps 610M20-B 688324 and up User Manual

Page 26

OM−01391

60 SERIES

MAINTENANCE & REPAIR

PAGE E − 7

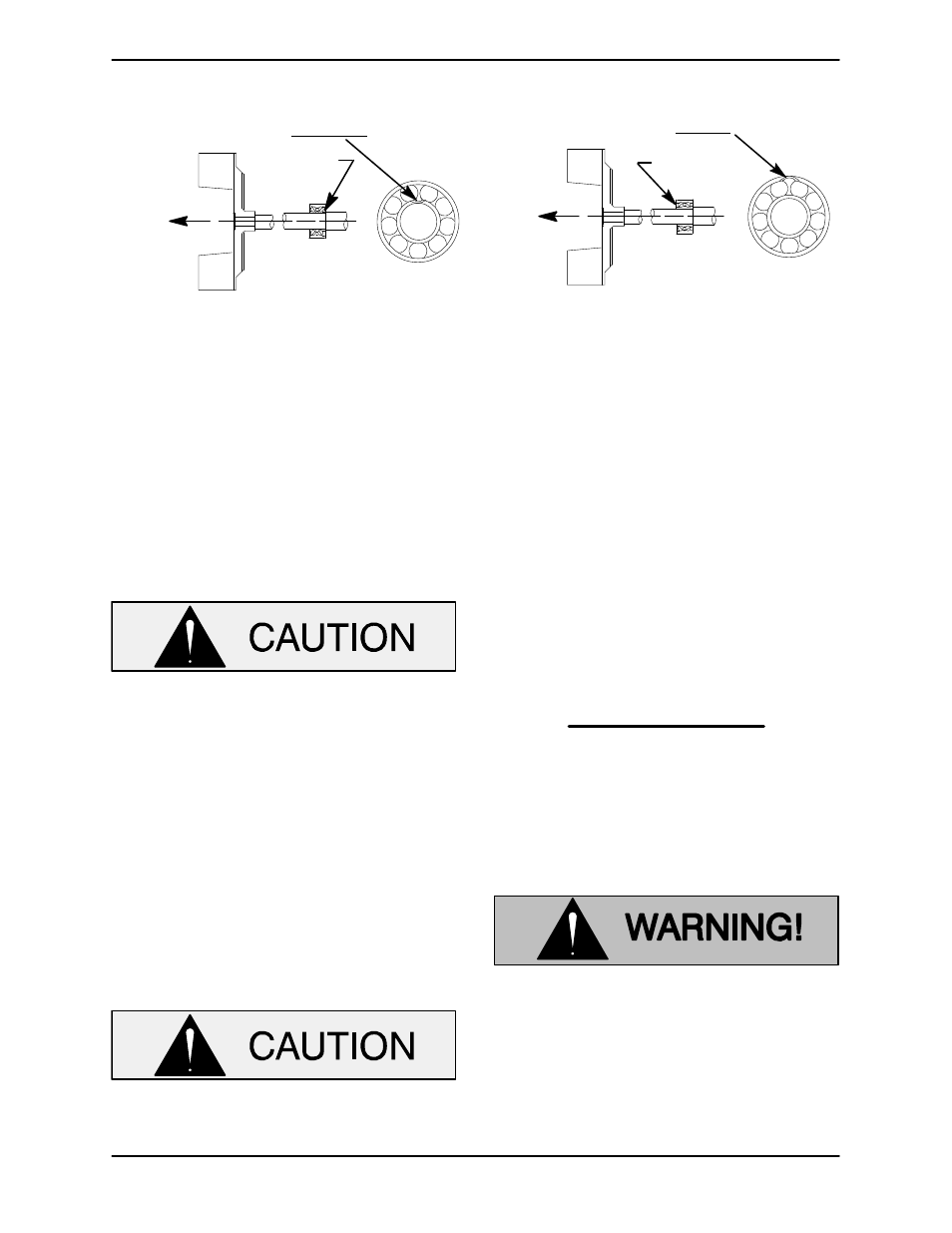

INSTALLATION OF FEDERAL MOGAL 5300W

OR NTN 3300 SERIES BEARINGS

(OPEN OR ENCLOSED IMPELLERS)

INSTALLATION OF MRC/SKF 5300M, 5300E OR

TIMKEN 5300W SERIES BEARINGS

(OPEN OR ENCLOSED IMPELLERS)

LOADING

DIRECTION OF

THRUST

BALL LOADING

GROOVE POSITIONED

AWAY FROM IMPELLER

GROOVE

DIRECTION OF

THRUST

LOADING

BALL LOADING

GROOVE POSITIONED

TOWARD IMPELLER

GROOVE

Figure 2. Inboard Bearing Position

After the bearings have been installed and allowed

to cool, check to ensure that they have not moved

out of position in shrinking. If movement has oc-

curred, use a suitably sized sleeve and a press to

reposition the bearings.

If heating the bearings is not practical, use a suit-

ably sized sleeve and an arbor (or hydraulic) press

to install the bearings on the shaft.

When installing the bearings onto the

shaft, never press or hit against the outer

race, balls, or ball cage. Press only on the

inner race.

After installation on the shaft, pack the bearings by

hand with No. 0 lithium based grease.

If removed secure the bearing cap gasket (34) and

bearing cap (35) to the pedestal (31) with the hard-

ware (36 and 37).

Slide the shaft and assembled bearings into the

pedestal bore until the inboard bearing (33) seats

squarely against the bearing cap (35).

When installing the shaft and bearings into

the bearing bore, push against the outer

race. Never hit the balls or ball cage.

Apply a light coating of oil to the lip of the oil seal

(28) and press it into the bearing cap (29) with the

lip positioned as shown in Figure 1. The face of the

oil seal should be just flush with the outer face of

the bearing cap.

Install the same thickness of bearing shims (30) as

previously remove. Install the bearing cap gasket

(23) and secure them to the pedestal with the hard-

ware (24 and 25). Be careful not to damage the lip

of the oil seal on the shaft keyway.

NOTE

Impeller shaft endplay should be between .002 and

.010 inch (0,05 to 0,25 mm). Add or subtract shims

to establish the correct endplay.

Seal Reassembly and Installation

(Figures 1 and 3)

Clean the seal cavity and shaft with a cloth soaked

in fresh cleaning solvent.

Most cleaning solvents are toxic and

flammable. Use them only in a well ven-

tilated area free from excessive heat,

sparks, and flame. Read and follow all

precautions printed on solvent contain-

ers.

The seal is not normally reused because wear pat-

terns on the finished faces cannot be realigned