Gorman-Rupp Pumps 610M20B-B 699260 and up User Manual

Page 27

OM−01912

60 SERIES

MAINTENANCE & REPAIR

PAGE E − 9

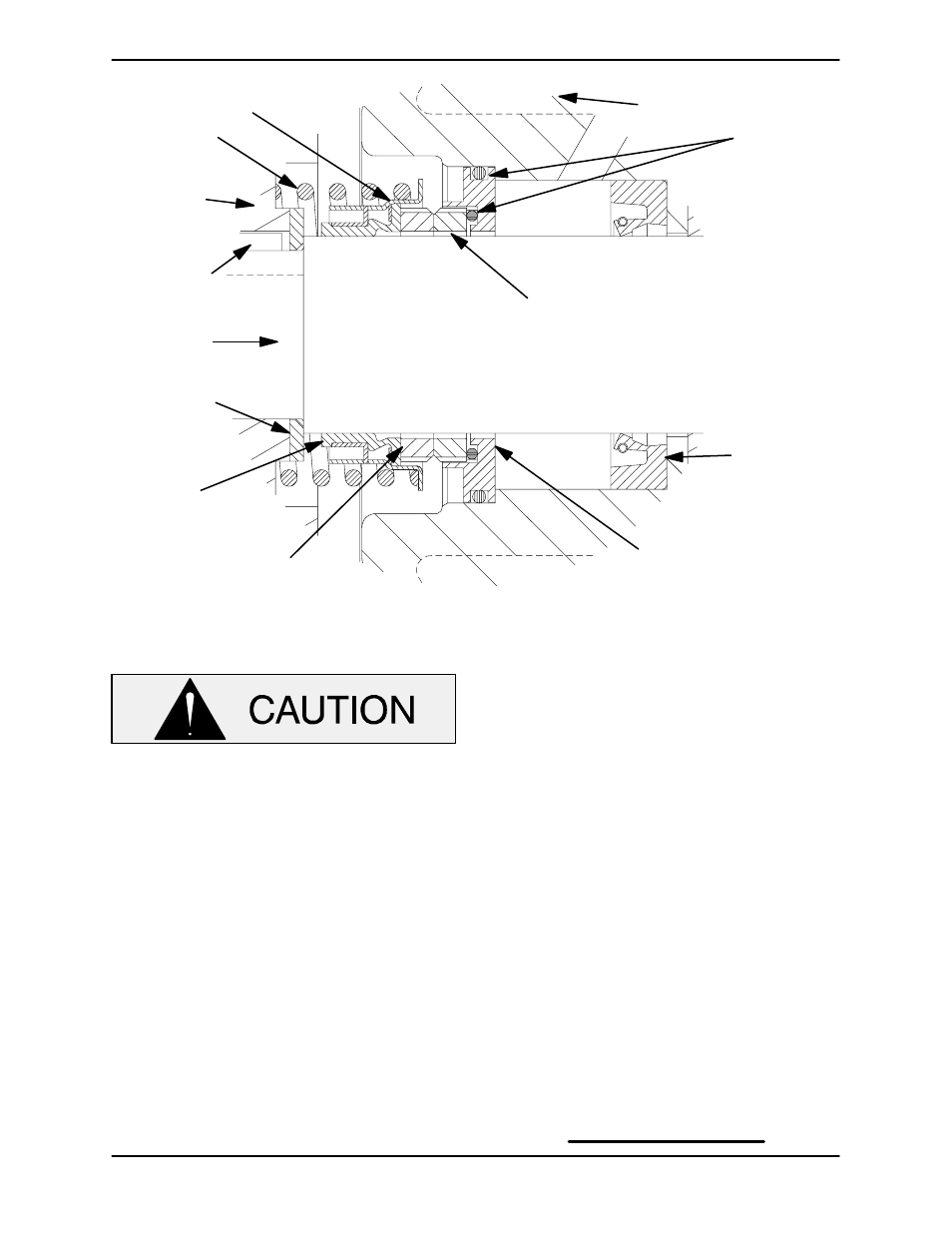

IMPELLER

SHAFT

SPRING

SEAL PLATE

RETAINER

OIL SEAL

BELLOWS

ROTATING

ELEMENT

STATIONARY

SEAT

IMPELLER

STATIONARY

ELEMENT

O-RINGS

IMPELLER

WASHER

IMPELLER

KEY

Figure 3. 12461A Seal Assembly

The standard seal is not designed for oper-

ation at temperatures above 160

_F (71_C).

Do not use at higher operating tempera-

tures.

Position the seal plate with the impeller side up and

press the oil seal (42) in the seal plate (5) with the lip

positioned as shown in Figure 1.

Lubricate the stationary seat O-ring with water or

light oil, and press the stationary subassembly

(consisting of the stationary seat, O-rings and sta-

tionary element) into the front of the seal plate until

it seats squarely against the bore shoulder.

Position the seal plate and stationary seat over the

shaft and secure it to the pedestal with the machine

screws (39). Be careful not to damage the station-

ary element on the shaft keyway.

Lubricate the shaft in the area of the seal, and slide

the rotating portion of the seal (consisting of the

bellows, retainer and rotating element) onto the

shaft until the seal faces contact.

Install the seal spring and washer (50).

Install new packing rings (10) in the back of the

seal plate seal plate as follows.

NOTE

It is recommended that replacement rings pre-cut

to the correct width and length, and packaged in a

set be ordered from the Gorman-Rupp Company or

your Gorman-Rupp distributor. However, if bulk

commercial packing will be used in the unit, pre-

pare and install the packing in accordance with the

steps outlined below in order to ensure that the

packing will form a tight seal.