Gorman-Rupp Pumps 68A2-B 818301 and up User Manual

Page 26

OM−01467

60 SERIES

MAINTENANCE & REPAIR

PAGE E − 5

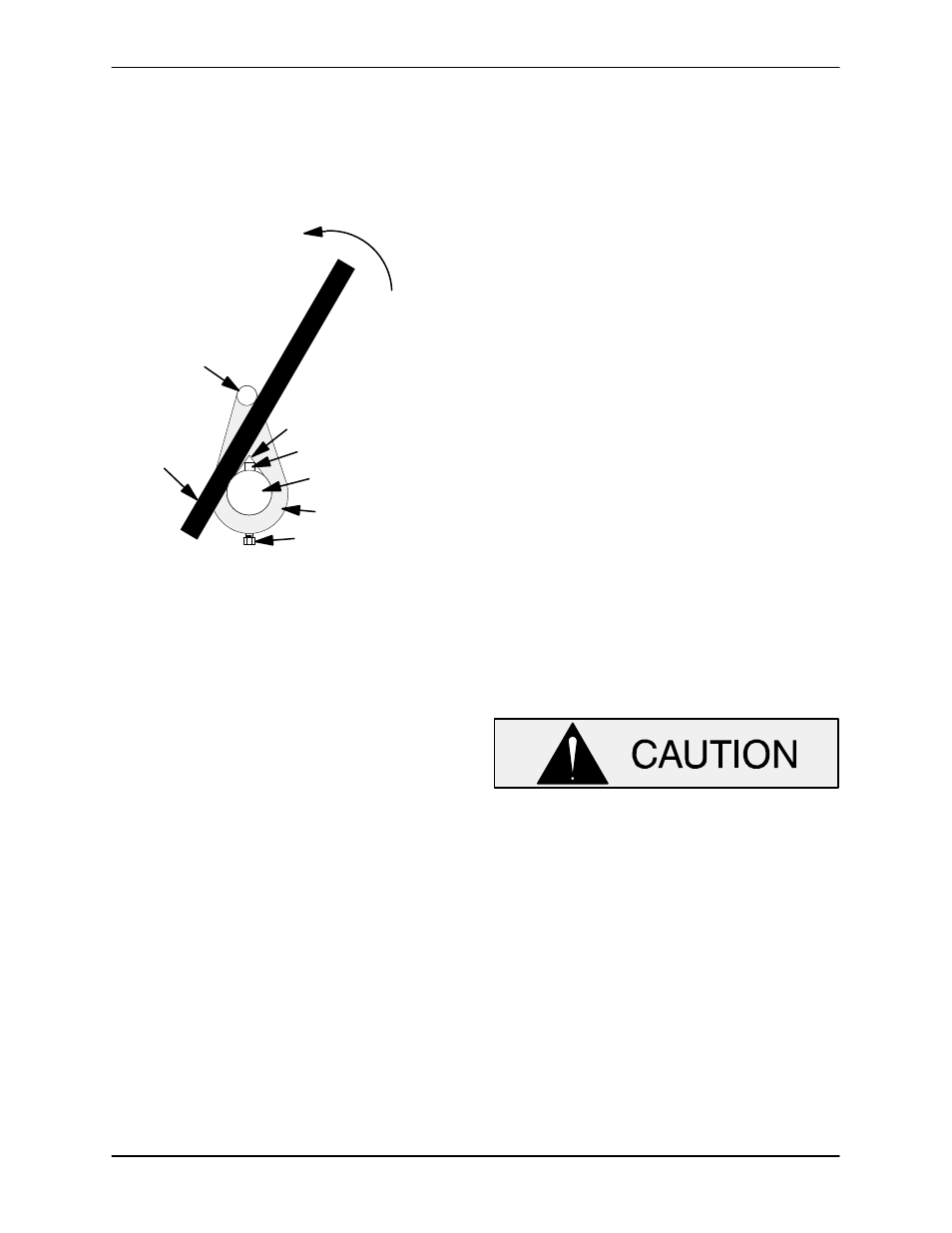

dog in a counterclockwise direction (when facing

the drive end of the shaft) as shown in Figure 2.

Use caution not to damage the shaft or keyway.

When the impeller breaks loose, remove the lathe

dog and wood block and unscrew the impeller

from the shaft.

Turn

Counterclockwise

Lathe Dog Arm

V" Notch

Shaft Key

Impeller Shaft

Lathe Dog

Setscrew

Heavy

Bar Stock

Figure 2. Loosening Impeller

Unscrew the impeller from the shaft. Use caution

when removing the impeller; tension on the seal

spring will be released as the impeller is un-

screwed.

Inspect the impeller and replace it if cracked or

badly worn. Slide the impeller adjusting shims (15)

off the impeller shaft. Tie and tag the shims, or

measure and record their thickness for ease of

reassembly.

Seal Removal and Disassembly

Remove the outer rotating element. Remove the

grease cup and piping (9, 10, 11 and 12) from the

seal plate (49).

Remove the hardware (43 and 44) and slide the

seal plate and remaining seal parts off the shaft as

a unit. Carefully remove the stationary and rotating

seal elements, packing rings and washers, seal

spring and spacer sleeve from the seal plate.

Inspect the seal plate and replace it if cracked or

badly worn. Inspect the wear ring (50) for exces-

sive wear or scoring. If replacement is required,

drill three holes horizontally, 120

_ apart, through

the wear ring. Use a chisel or other suitable tool to

complete the cuts. Use caution not to damage the

seal plate bore. Remove the wear ring sectons

from the seal plate.

Inspect the seal liner (14) for wear or grooves that

could cause leakage or damage to the seal pack-

ing rings. The seal liner is a press fit into the seal

plate and does not normally require replacement. If

replacement is required, see Seal Installation.

Pump Casing and Pedestal Adaptor Removal

To remove the pump casing (1), support the casing

using a suitable hoist and sling and remove the

hardware (39 and 40) securing the casing to the

pedestal adaptor (8). Remove the casing by pull-

ing it straight away from the adaptor.

If the pedestal (27) is to be serviced, disengage the

hardware (5, 6 and 7) and separate the pedestal

adaptor from the pedestal.

Shaft And Bearing Removal And Disassembly

When the pump is properly operated and main-

tained, the pedestal should not require disassem-

bly. Disassemble the shaft and bearings only

when there is evidence of wear or damage.

Shaft and bearing disassembly in the field

is not recommended. these operations

should be performed only in a properly-

equipped shop by qualified personnel.

Remove the pedestal drain plug (31) and drain the

pedestal. Clean and reinstall the plug.

Remove the slinger ring (13) from the shaft. Re-

move the pedestal mounting hardware from the

base. Tie and tag any shims used under the

mounting feet for leveling.

Use snap ring pliers to remove the bearing retain-

ing ring (28) from the pedestal bore. Remove the

bearing shim set (29); tie and tag the shims, or

measure and record their thickness for ease of

reassembly.