Gorman-Rupp Pumps VGH2D31-B 1379872 thru 1211808 User Manual

Page 30

VGH SERIES

OM−06118

MAINTENANCE & REPAIR

PAGE E − 8

Do not attempt to separate the seal, this could

damage the seal. Individual parts are not sold sep-

arately.

Inspect the seal for wear, scoring, grooves, and

other damage that might cause leakage. If any

components are worn, replace the seal.

If a replacement seal is being used, remove it from

the container and inspect it to ensure that it is free

of any foreign matter.

To ease installation of the seal and seal plate, lubri-

cate the seal sleeve O-ring with water or a very

small amount of oil. See Figure 2 for seal part iden-

tification.

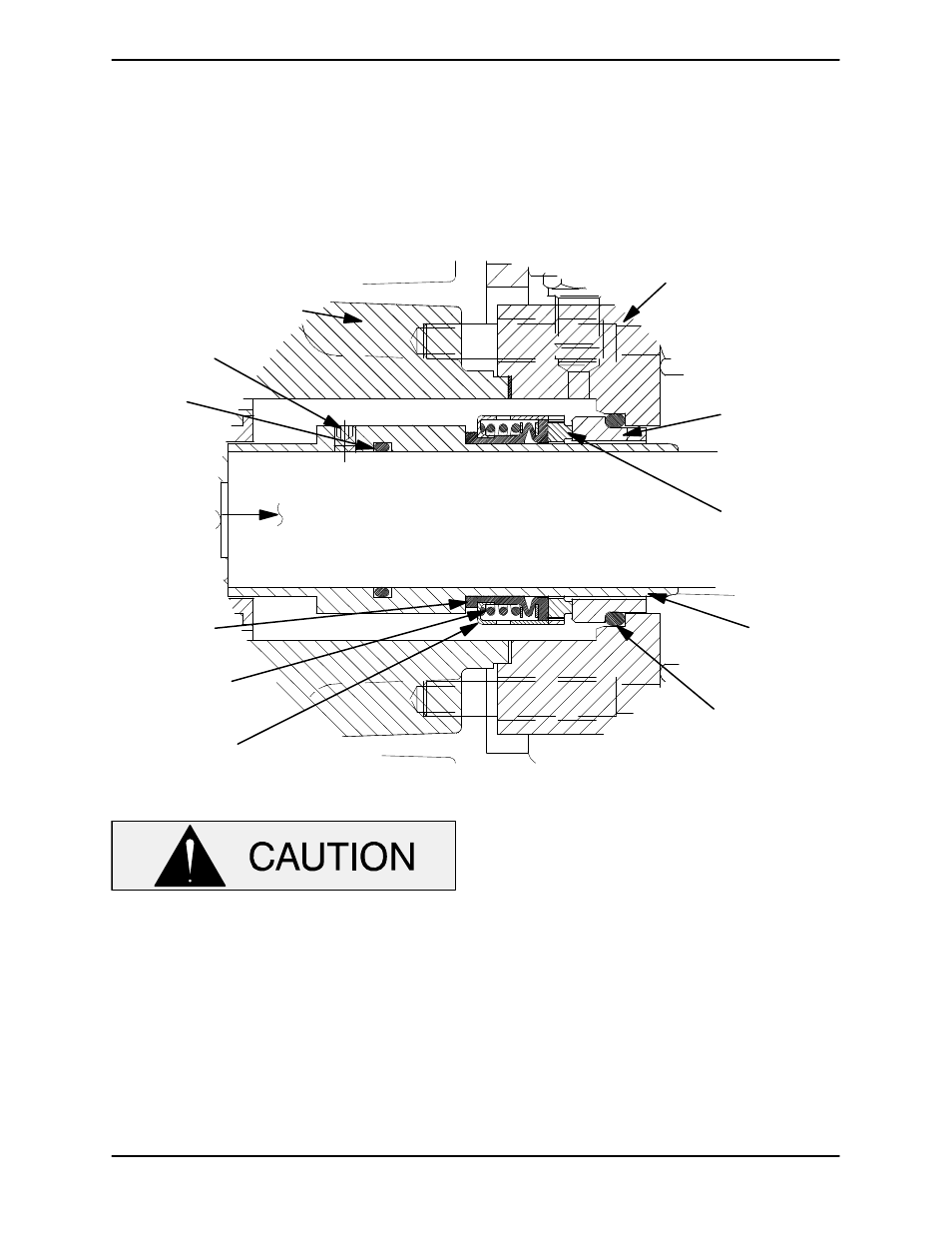

SEAL PLATE

IMPELLER

SHAFT

STATIONARY

SEAT

ROTATING

ELEMENT

CAGE

SHAFT

SLEEVE

SET SCREW

O-RING

SEAL FLANGE

BELLOWS

SPRING

STATIONARY

SEAT O-RING

Figure 2. Cartridge Seal Assembly

This seal is not designed for operation at

temperatures above 160

_

F (71

_

C). Do not

use at higher operating temperatures.

Lubricate the O-ring (40) with water or light oil and

install it in the groove in the I.D. of the shaft sleeve

(57). Lubricate the O.D. of the sleeve in the area of

the seal with water or light oil and slide the rotating

portion of the seal onto the shaft until it is fully

seated against the step on the O.D. of the shaft

sleeve.

Lubricate the stationary seat O-ring with water or

light oil and install it on the O.D. of the stationary

seat. Align the hole in the stationary seat with the

hole for the pin (11) in the seal flange (37) and use

thumb pressure to press the stationary seat and O-

ring into the seal flange until fully seated. After

installation, wipe the stationary seat face in a con-

centric pattern with a clean, lint-free cloth to re-

move any fingerprints. Screw the pin into the seal

flange to secure the stationary seat.

Carefully slide the assembled stationary seat and

flange over the end of the shaft sleeve until the seal

faces contact.

Slide the assembled shaft sleeve, seal and seal

flange over the shaft until the impeller end of the