Gorman-Rupp Pumps 62 1/2A1-L100 S/G S2 93740 CA and up User Manual

Page 24

60 SERIES

OM−06224

MAINTENANCE & REPAIR

PAGE E − 8

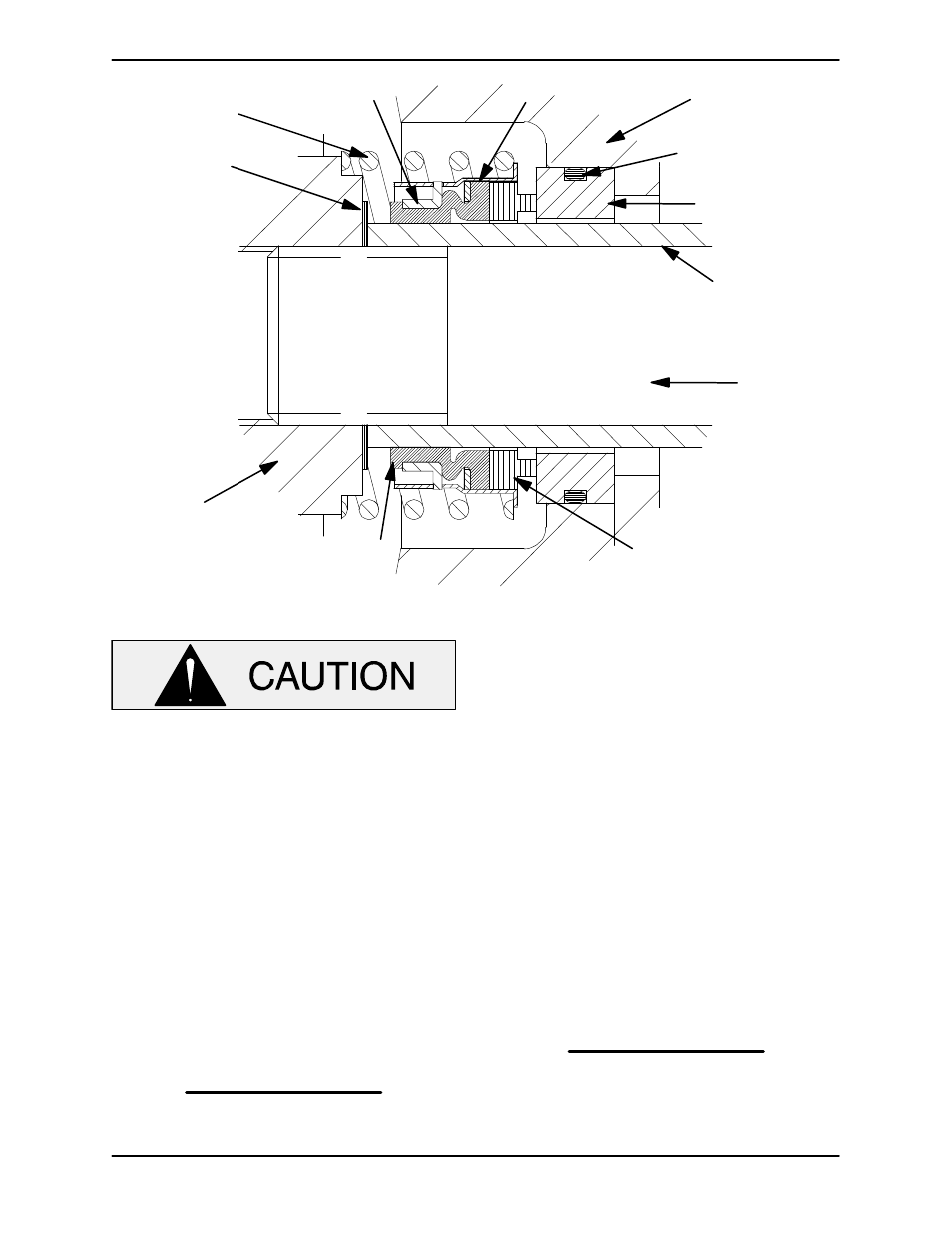

O-RING

STATIONARY

SEAT

SHAFT SLEEVE

INTERMEDIATE

ROTATING ELEMENT

BELLOWS

SHAFT

IMPELLER

IMPELLER ADJ SHIMS

SPRING

DRIVE BAND

RETAINER

Figure 3. 25271−192 Seal Assembly

This seal is not designed for operation at

temperatures above 160

_ F (71_C). Do not

use at higher operating temperatures.

If the intermediate was removed, lay it on a flat sur-

face with the impeller side facing up. Subassemble

the O-ring in the stationary seat and press it into the

intermediate bore until it seats squarely against the

shoulder. Install the seal ring (7) on the shaft and

secure the intermediate to the engine with the

hardware (18 and 20, Figure 1). Be careful not to

damage the stationary seat on the shaft threads.

NOTE

If the intermediate was not removed, subassemble

the O-ring in the stationary seat and use thumb

pressure to press it into the intermediate bore until it

seats squarely against the shoulder.

Subassemble the rotating element in the retainer

and bellows, then slide this subassembly onto the

shaft sleeve (5) until the face of the rotating element

is just flush with the chamfered end of the sleeve.

Slide the sleeve onto the shaft until the seal faces

contact. Continue to push the sleeve through the

seal until it seats against the seal ring (7).

Position the seal spring on the retainer and pro-

ceed with Pump Reassembly.

Pump Reassembly

(Figure 2)

If the wear ring (12) was removed, press the re-

placement ring into the casing bore until fully

seated against the casing shoulder.

NOTE

The wear ring

must seat squarely in the casing bore

or binding and/or excessive wear will result.

Inspect the impeller and replace it if cracked or

badly eroded. Install the same thickness of impel-

ler shims (4) as previously removed and screw the

impeller onto the shaft until tight.