Gorman-Rupp Pumps T10A65S-B /FM User Manual

Page 29

OM-05522

SUPER T SERIES

MAINTENANCE & REPAIR

PAGE E - 7

shoulder‐type coupling (11) and separate the valve

body (4) and check valve from the suction head.

Separate the check valve from the valve body as de

scribed above.

Replace the cleanout cover gasket (12) before re

installing the cover.

Suction Head And Wear Plate Removal

(Figure E‐1)

To remove the suction head, support it with a suit

able hoist and sling and remove the hardware (47,

48, 49 and 50) securing it to the pump casing. Re

move the suction head gasket (45).

If the wear plate (38) does not slide easily from the

casing bore, position a wood or soft metal wedge

between the impeller vanes and the wear plate,

and tap the wedge with a hammer. Turn the impel

ler every 45

_, repeating the process until the wear

plate is “walked” out of the pump casing.

Rotating Assembly Removal

(Figure E‐2)

The rotating assembly (2, Figure 1) may be re

moved from either side of the casing; however, it is

recommended that it be removed through the suc

tion head opening.

The impeller (1) should be loosened while the rotat

ing assembly is still secured to the pump casing.

Before loosening the impeller, remove the seal cav

ity drain plug (27A) and drain the seal lubricant.

This will prevent the oil in the seal cavity from es

caping as the impeller is loosened. Clean and rein

stall the seal cavity drain plug.

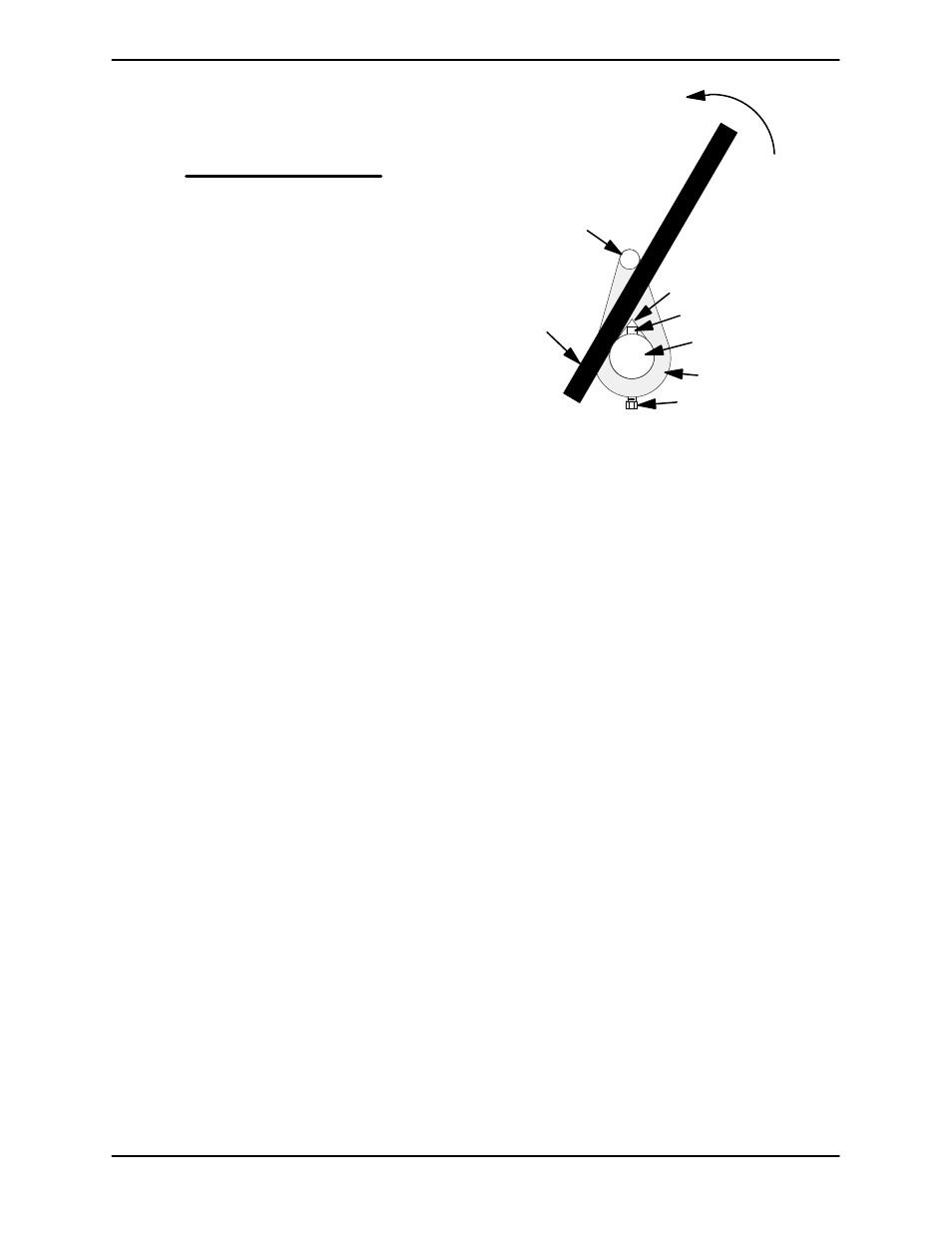

Turn

Counterclockwise

Lathe Dog Arm

“V” Notch

Shaft Key

Impeller Shaft

Lathe Dog

Setscrew

Heavy

Bar Stock

Figure E‐3. Loosening Impeller

Immobilize the impeller by wedging a block of

wood between the vanes, and remove the impeller

capscrew and washer (24 and 27). See Figure E‐3,

and install a lathe dog on the drive end of the shaft

(18) with the “V” notch positioned over the shaft

keyway. Use a long piece of bar stock to turn the

shaft in a counterclockwise direction (when facing

the drive end of the shaft). When the impeller

breaks loose, remove the wood block and lathe

dog. Do not fully unscrew the impeller from the

shaft at this time.

(Figure E‐1)

An optional disassembly tool for removing and in

stalling the rotating assembly is available from the

factory. If improvised tools are used, be sure they

are heavy enough for safe use and will not damage

the pump.

Remove the inner hardware (30 and 31) from the

casing ring (27). If the removal tool is used, follow

the instructions packaged with it, and pull the rotat

ing assembly from the pump casing (see Figure

E‐4 for removal tool use). If the removal tool is not

used, install three of the inner capscrews in the

jacking holes in the casing ring, and use them to

press the rotating assembly into the pump casing

until the bearing housing is free.

Remove the jacking screws from the casing ring.

Remove the outer hardware (28 and 29) and shim

sets (26). Separate the casing ring from the pump

casing. Tie and tag the shim sets for ease of reas

sembly.