Gorman-Rupp Pumps T3A71S-B /F,/FM User Manual

Page 36

OM-05349

SUPER T SERIES

MAINTENANCE & REPAIR

PAGE E - 14

NOTE

If the suction or discharge flanges were removed,

replace the respective gaskets, apply `Permatex

Aviation No. 3 Form‐A‐Gasket' or equivalent com

pound to the mating surfaces, and secure them to

the pump casing with the attaching hardware.

Back Cover Installation And Adjustment

(Figure 1 and 8)

If the wear plate (12) was removed for replace

ment, carefully center it on the back cover and se

cure it with the hardware (14 and 15). The wear

plate must be concentric to prevent binding when

the back cover is installed.

Clearance between the impeller and wear plate is

adjusted using four adjusting screws and locking

collars (29 and 30). There are 18 detents on the I.D.

of each locking collar. Indexing the collars one det

ent on the adjusting screws represents approxi

mately .005 inch (0,13 mm) of wear plate clear

ance. The recommended clearance between the

wear plate and the impeller is .010 to .020 inch

(0,25 to 0,50 mm).

Replace the back cover O‐rings (13 and 17), and

lubricate them with a generous amount of No. 2

grease. Clean any scale or debris from the contact

ing surfaces in the pump casing that might inter

fere or prevent a good seal with the back cover.

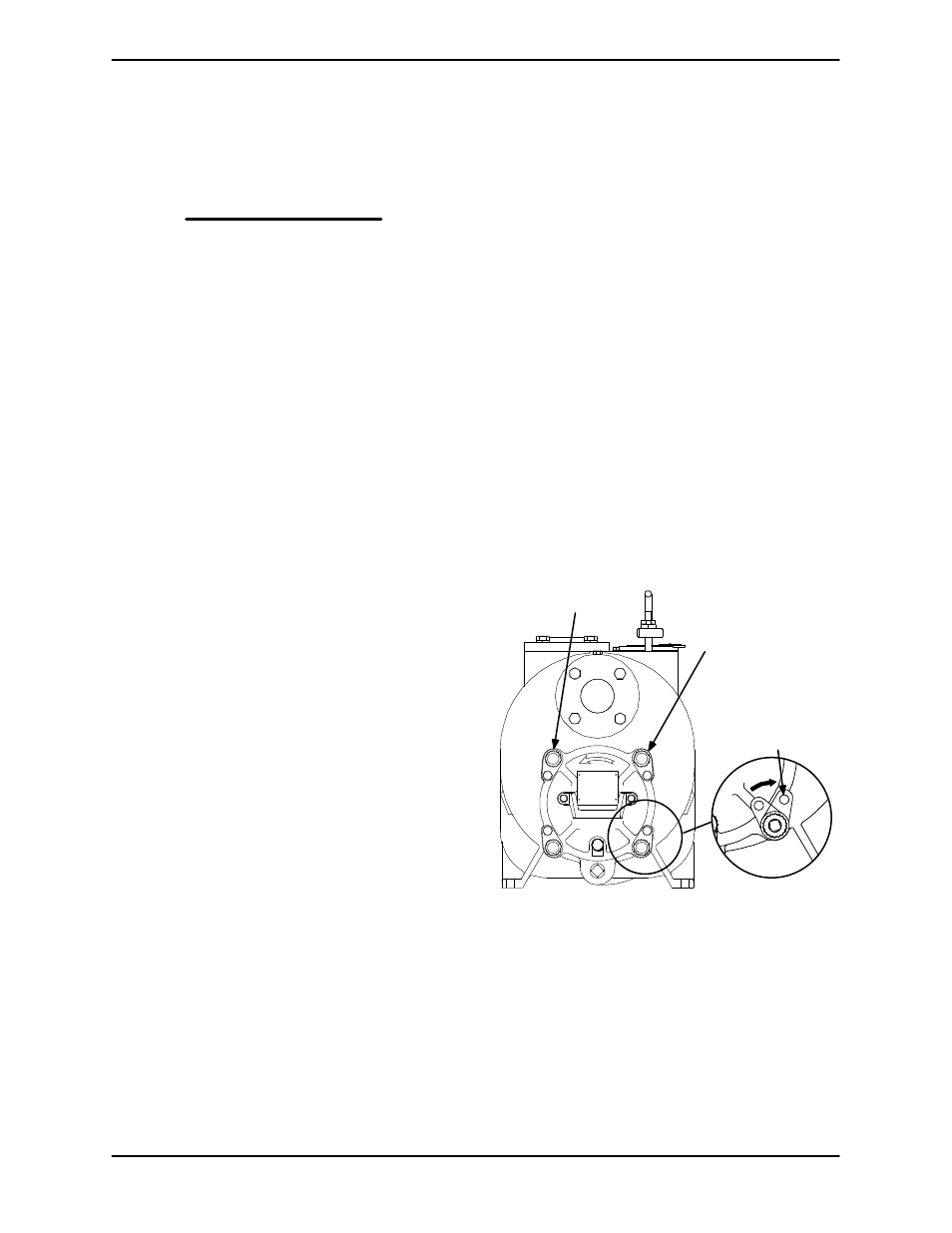

USE TWO

OPPOSING

BACK COVER NUTS

TO PRESS

BACK COVER

INTO PUMP

CASING

USE TWO REMAINING

ADJUSTING SCREWS AND

LOCKING COLLARS TO

SET FACE CLEARANCE

INDEX COLLARS 3

DETENTS COUNTER‐

CLOCKWISE, THEN

TURN CLOCKWISE

UNTIL SCREW

HOLES ALIGN

Figure 8. Installing and Adjusting Back Cover

Screw the four adjusting screws (30) into the

tapped holes in the back cover plate until they are

just flush with the machined surface on the back

side of the cover plate.

Align the back cover plate over the studs (32) and

slide it into the pump casing. Use two back cover

nuts (31) on diagonally opposing studs to press

the back cover into the pump casing until the wear