Gorman-Rupp Pumps 03C51-B 1341129 and up User Manual

Page 27

0 SERIES

OM-01141

MAINTENANCE & REPAIR

PAGE E - 8

This seal is not designed for operation at

temperatures above 160

_F (71_C). Do not

use at higher operating temperatures.

Clean all of the old adhesive from the face of the

seal plate before installation. Position the seal plate

(21) on a flat surface with the impeller side facing

up.

Subassemble the O‐ring onto the stationary ele

ment and use even pressure to press this subas

sembly into the seal plate bore until it seats square

ly against the shoulder bore.

Carefully slide the assembled seal plate and sta

tionary seat over the shaft. Use caution not to nick

or damage the stationary seat. Temporarily secure

the seal plate to the pedestal (21) using two cap

screws and nuts (1/2 UNC X 1 1/2 inch long, not

supplied).

Subassemble the rotating element into the retainer

and bellows. Lubricate the I.D. of the bellows with

water, and slide this subassembly over the shaft

until the polished faces contact.

Install the seal spring and spring centering washer

(15).

Impeller Installation

Inspect the impeller and replace it if cracked or

badly worn.

For maximum pump efficiency, the impeller should

be centered within the vane plate (24).

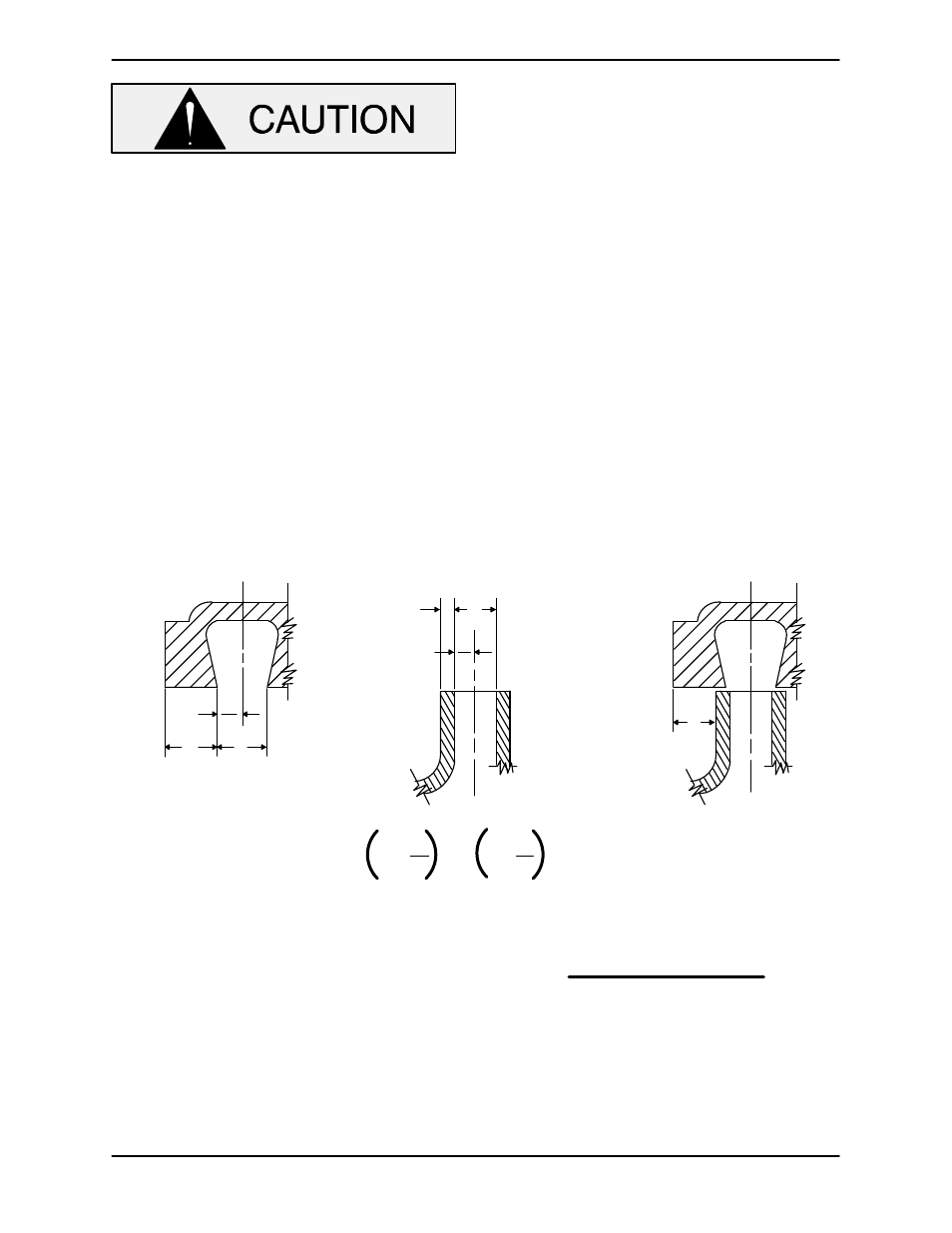

To verify the impeller positioning, measure the

vane plate and impeller as shown in Figure 3. Use

these measurements to calculate the required im

peller location (dimension E). Add or remove im

peller adjusting shims (16) until dimension E is ob

tained.

D

B

2

A

B

2

C

D

E

Step 2

Step 1

Step 3

A+

B

2

C+

D

2

E

=

-

Figure 3. Centering Impeller Within Vane Plate

Install the correct thickness of impeller shims and

install the impeller key (7) in the shaft keyway. The

impeller key should protrude approximately 3/16

inch (4,7 mm) from the end of the shaft. Align the

impeller keyway with the key and slide the impeller

onto the shaft until fully seated.

NOTE

After the impeller has been properly positioned,

check for free rotation. Correct any scraping bind

ing before further reassembly.

When the impeller is properly positioned, install the

impeller washer (25) with the hole positioned over

the end of the key (7). Immobilize the impeller by

wedging a soft brass rod between the vanes, and

secure the impeller and washer the hardware (26

and 27). Torque the capscrew to 20 ft. lbs. (2.8 m.

kg.).