Gorman-Rupp Pumps 03H1-GX390 1178614 and up User Manual

Page 27

OM-04728

0 SERIES

MAINTENANCE & REPAIR

PAGE E - 9

not to damage the stationary seat on the shaft

threads.

NOTE

If the intermediate was not separated from the en

gine during disassembly, subassemble the O‐ring

into the stationary seat, and use a piece of plastic

pipe to press the seat into the intermediate bore un

til fully seated. The O.D. of the pipe should be ap

proximately the same as the O.D. of the seal spring.

Subassemble the rotating element into the retainer

and bellows, then slide this subassembly onto the

shaft sleeve (13) until the face of the rotating ele

ment is just flush with the chamfered end of the

sleeve.

Slide the sleeve and seal parts onto the shaft until

the seal faces contact. Continue to push the sleeve

through the seal until the chamfered end seats

firmly against the shaft shoulder.

Install the seal spring and spring centering washer

(11).

Impeller Installation

(Figure 2)

Inspect the impeller (2), and replace it if cracked or

badly worn. Install the same thickness of impeller

shims (12) as previously removed, and screw the

impeller onto the shaft until tight.

Pump Casing and Wear Ring Installation

(Figure 2)

If the wear ring (22) was removed for replacement,

press the replacement ring into the pump casing

until it seats squarely against the shoulder bore.

The wear ring must seat squarely in the

casing bore or binding and/or excessive

wear will result.

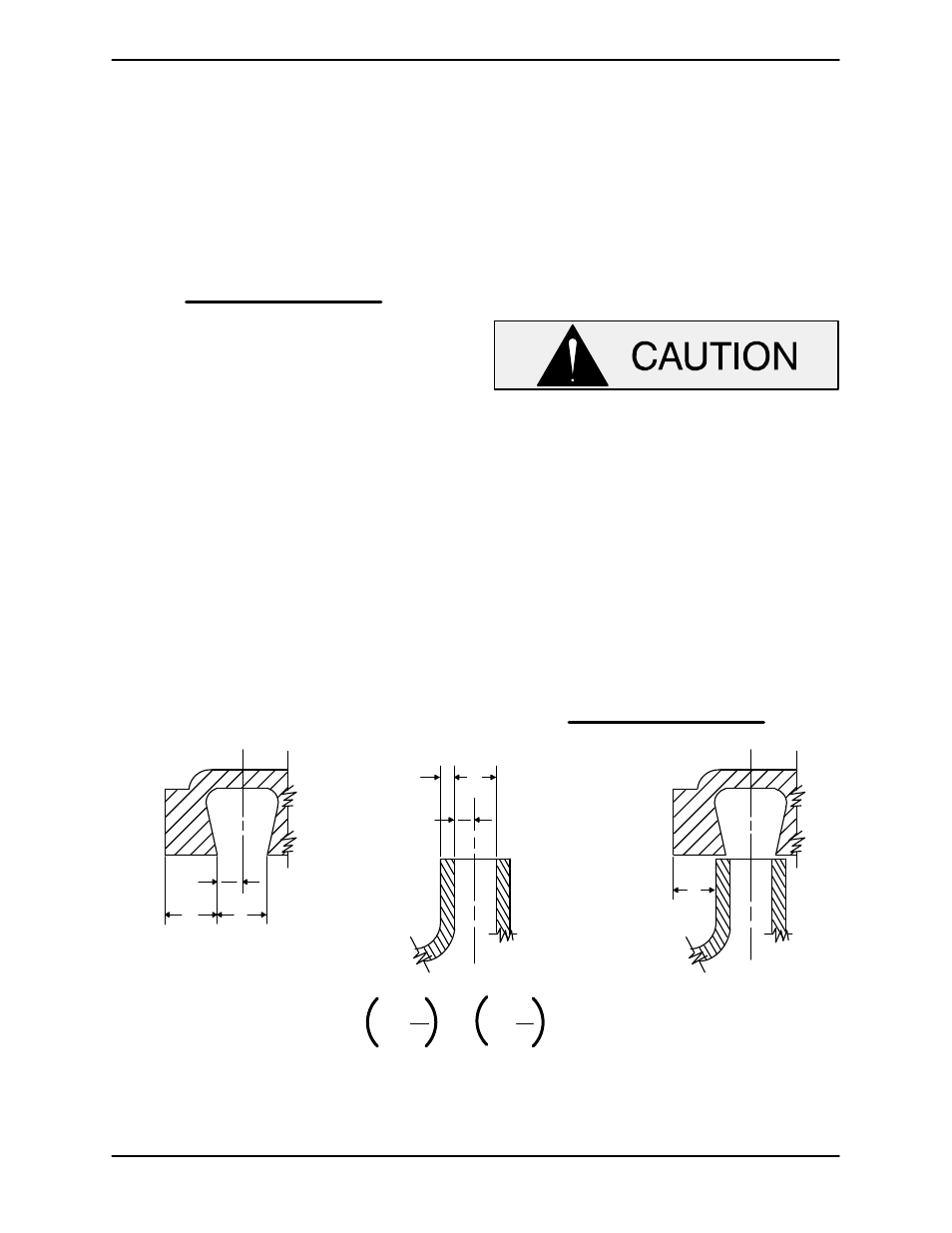

For maximum pump efficiency, the impeller should

be centered within the pump casing. To verify im

peller positioning, measure the pump casing and

impeller as shown in Figure 4. Use these measure

ments to calculate the required impeller location

(dimension E). Add or remove gaskets in the pump

casing gasket set (14) to obtain dimension E.

NOTE

When calculating pump casing positioning, Figure

20% compression for pump casing gaskets.

D

B

2

A

B

2

C

D

E

Step 2

Step 1

Step 3

A+

B

2

C+

D

2

E

=

-

Figure 4. Centering Impeller Within Pump Casing

Install the calculated thickness of pump casing

gaskets. Coat the threads of the studs (15) with

pipe sealant, and secure the pump casing to the in

termediate with the nuts (16).