Gorman-Rupp Pumps 02K11-X2 1P 384050 and up User Manual

Page 24

OM-01160

0 SERIES

MAINTENANCE & REPAIR

PAGE E - 6

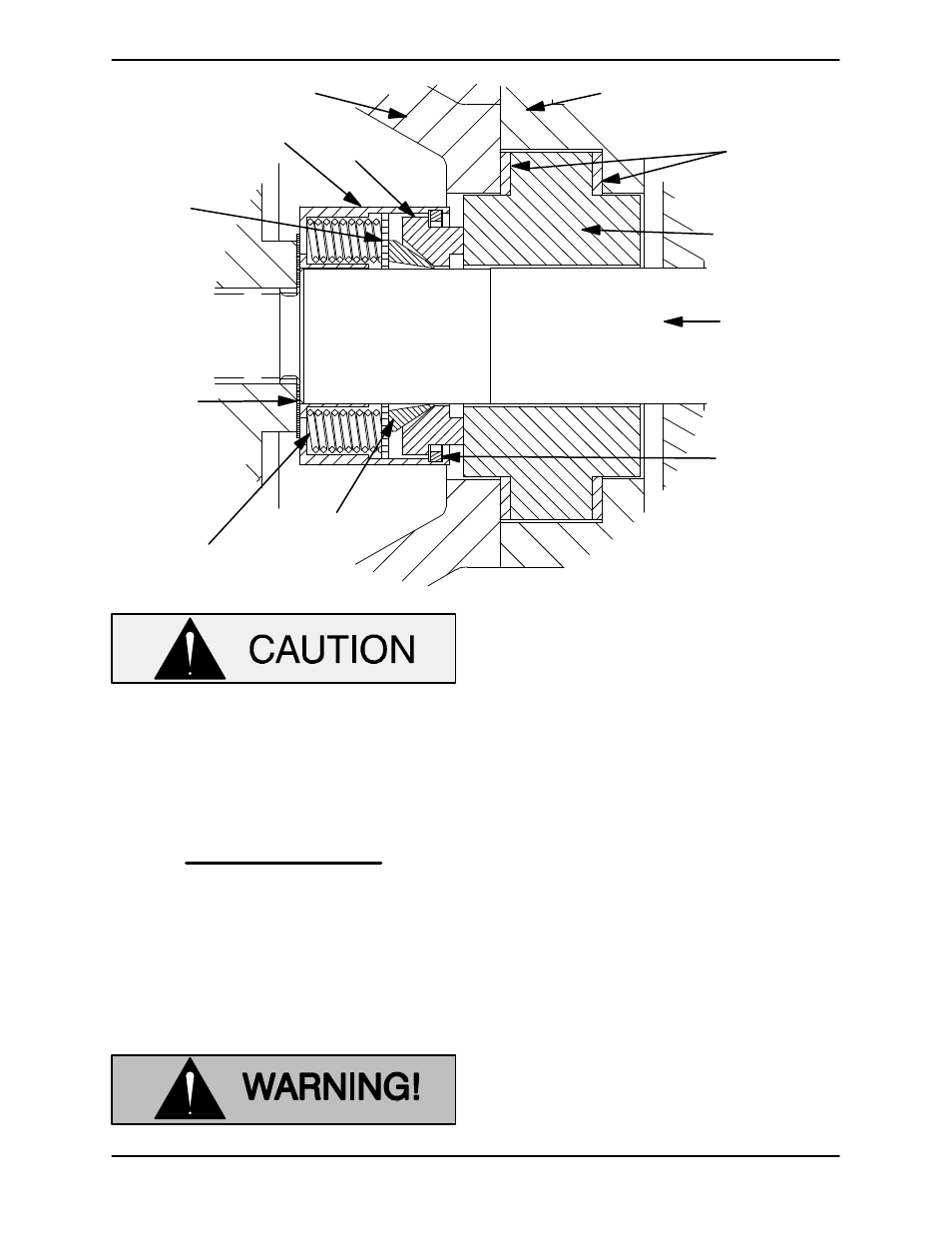

SEAL CAP

IMPELLER

SHAFT

STATIONARY

SEAT

SNAP RING

ROTATING

ELEMENT

IMPELLER

SHIMS

DISC

SPRING

GASKETS

SEALING

WEDGE

INTERMEDIATE

RETAINER

Figure 2. Seal Assembly

This seal is not designed for operation at

temperatures above 160

_F (71_C). Do not

use at higher operating temperatures.

NOTE

The white “Chemlon” stationary seat gasket must

be installed on the seal cavity side of the stationary

seat.

Assemble the stationary seat and gaskets in the

seal cap (20) and secure to them to the intermedi

ate with the hardware (14 and 15).

Slide the assembled intermediate and stationary

portion of the seal over the shaft and secure the in

termediate to the motor housing with the previous

ly removed hardware (12 and 13).

New seal assemblies may be equipped

with spring holding clips for storage

purposes. Remove and discard these

clips before proceeding with seal reas

sembly. When removing the clips, use

caution so that they do not pop off

abruptly and cause personal injury. Fail

ure to remove these clips can result in

seal failure and pump damage.

A new seal assembly may be furnished with re

straining clips which keep the wedge from being

compressed prior to assembly. Remove and dis

card the seal spring restraining clips.

Lubricate the I.D. of the wedge and rotating ele

ment with water or a very small amount of oil, and

slide the rotating portion of the seal assembly onto

the shaft until the seal faces contact.

Impeller Installation

Inspect the impeller and replace it if cracked or

badly worn.

For maximum pump efficiency, the impeller should

be centered within the vane plate scroll.

To verify the impeller positioning, measure the

vane plate and impeller as shown in Figure 3. Use