Gorman-Rupp Pumps 82H3-B 716123 and up User Manual

Page 27

OM−00831

80 SERIES

MAINTENANCE & REPAIR

PAGE E − 8

Wipe lightly in a concentric pattern to avoid

scratching the faces.

Inspect the seal components for wear, scoring,

grooves, and other damage that might cause leak-

age. Clean and polish the shaft sleeve, or replace it

if there are nicks or cuts on either end. If any com-

ponents are worn, replace the complete seal;

never mix old and new seal parts.

If a replacement seal is being used, remove it from

the container and inspect the precision finished

faces to ensure that they are free of any foreign

matter.

To ease installation of the seal, lubricate the bel-

lows, sleeve and stationary seat O-ring with water

or a very small amount of light lubricating oil, and

apply a drop of light lubricating oil on the finished

faces. Assemble the seal as follows (see Figure 3).

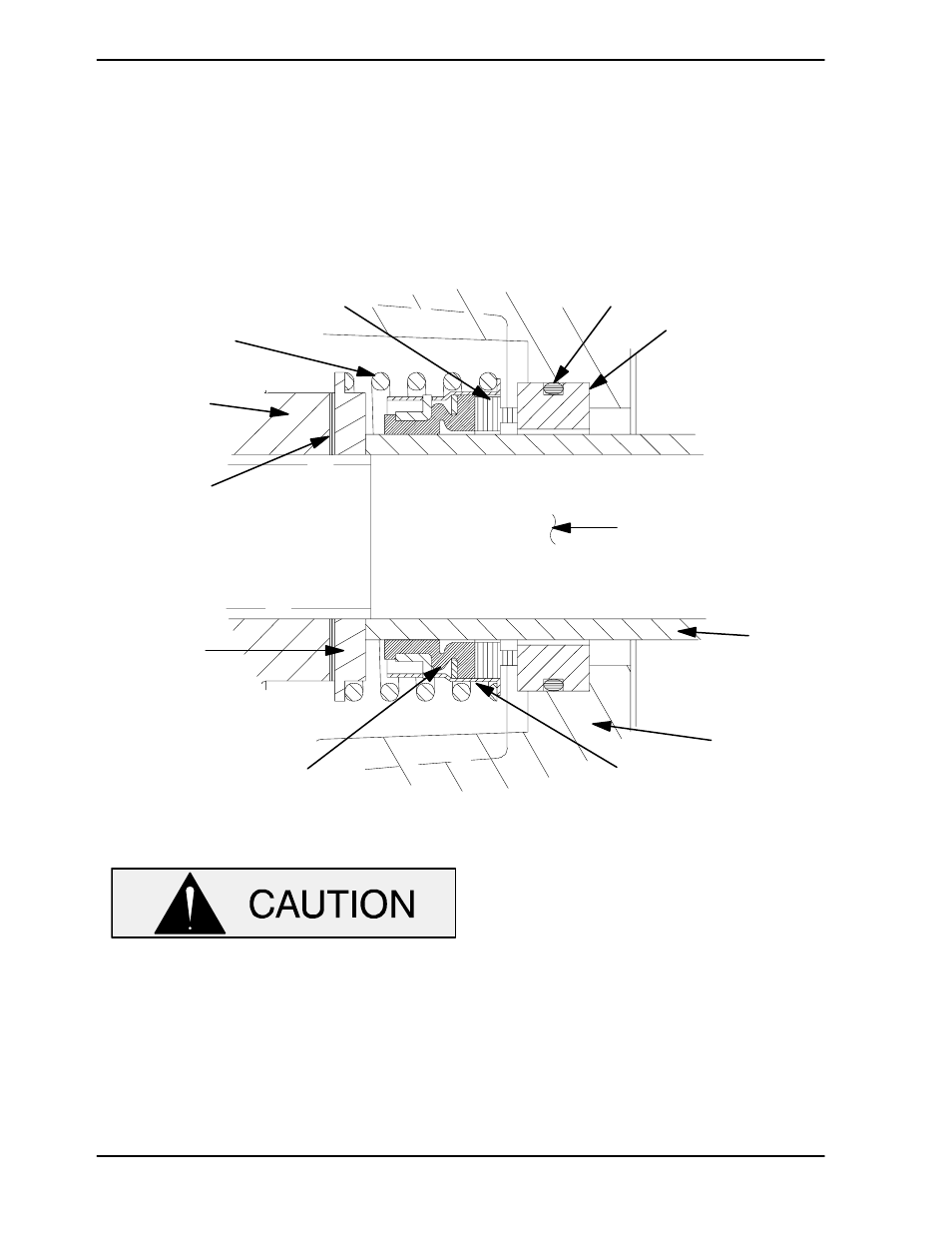

IMPELLER

SHAFT

SEAL

PLATE

ROTATING

ELEMENT

SPRING

SEAT

RETAINER

SPRING

IMPELLER

ADJUSTING

SHIMS

IMPELLER

BELLOWS

SHAFT

SLEEVE

O-RING

STATIONARY

SEAT

Figure 3. 25271−192 Seal Assembly

This seal is not designed for operation at

temperatures above 160

_F (71_C). Do not

use at higher operating temperatures.

Position the seal plate (27) on a flat surface with the

impeller side facing up. Apply oil to the stationary

seat O-ring and use thumb pressure to press the

stationary seat into the seal plate bore until fully

seated. A push tube made from a piece of plastic

pipe would aid this installation. The I.D. of the tube

should be approximately the same as the I.D. of the

seal spring.

Slide the assembled seal plate and stationary seat

over the impeller shaft (16) and temporarily secure

the seal plate to the pedestal (10) using two cap-

screws and nuts (1/2 UNC x 1 1/2 inch long, not

supplied).

Lubricate the O.D. of the shaft sleeve with water or

a very small amount of oil, and slide the rotating

portion of the seal assembly onto the shaft sleeve

until the face of the rotating element is just flush

with the chamfered end of the sleeve.