Gorman-Rupp Pumps 82H65-B 1015831 and up User Manual

Page 27

80 SERIES

OM−03696

MAINTENANCE & REPAIR

PAGE E − 8

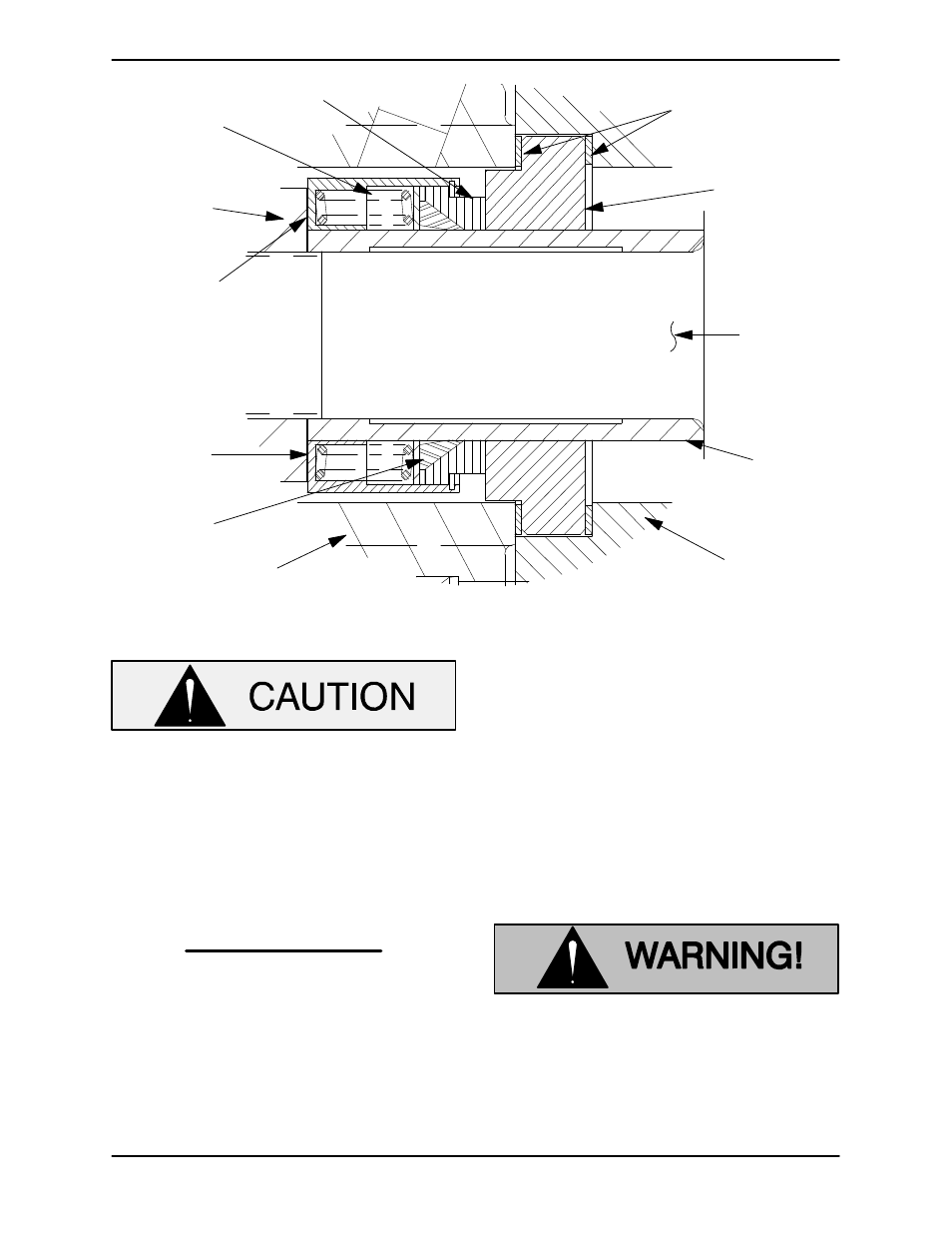

IMPELLER

SHAFT

STATIONARY

ELEMENT

SEAL

CLAMP

ROTATING

ELEMENT

SEALING

WEDGE

RETAINER

SPRING

IMPELLER

ADJUSTING

SHIMS

IMPELLER

SEAL

PLATE

SHAFT

SLEEVE

GASKETS

Figure 2. 25271−744 Seal Assembly

This seal is not designed for operation at

temperatures above 160

_F (71_C). Do not

use at higher operating temperatures.

Assemble the stationary seat and gaskets in the

seal clamp (7) and secure to the seal plate (31).

NOTE

The white Chemlon" seat gasket must be installed

on the seal cavity side of the stationary seat.

Slide the assembled seal plate and stationary seat

over the impeller shaft (18) and temporarily secure

the seal plate to the pedestal (13) using two cap-

screws and nuts (1/2 UNC X 1 1/2 inch long, not

supplied).

Lubricate the I.D. of the wedge and disc with water

or a very small amount of oil, and slide the rotating

portion of the seal assembly onto the shaft sleeve.

Make certain that the seal face is toward the cham-

fered end of the sleeve. Position the seal on the

sleeve with the retainer just flush with the impeller

end of the sleeve. Tighten the retainer setscrews

with an allen wrench and lock in place with a punch

to prevent loosening.

A new seal assembly is furnished with restraining

clips which keep the wedge from being com-

pressed prior to assembly. Remove and discard

the seal spring restraining clips before installin

the seal.

New seal assemblies are equipped with

spring holding clips for storage pur-

poses. Remove and discard these clips

before proceeding with seal reassemb-

ly. When removing the clips, use caution

so that they do not pop off abruptly and

cause personal injury. Failure to remove