Lubrication – Gorman-Rupp Pumps 88B2-B 818301 and up User Manual

Page 31

80 SERIES

OM−00985

MAINTENANCE & REPAIR

PAGE E − 10

tight, and that the weight of the lines is indepen-

dently supported and secure.

Before starting the pump, fill the pump casing with

clean liquid. Apply Never-Seez" or equivalent

compound to the fill plug (8). Reinstall and tighten

the fill plug.

Refer to OPERATION, Section C, before putting

the pump back into service.

LUBRICATION

Seal Assembly

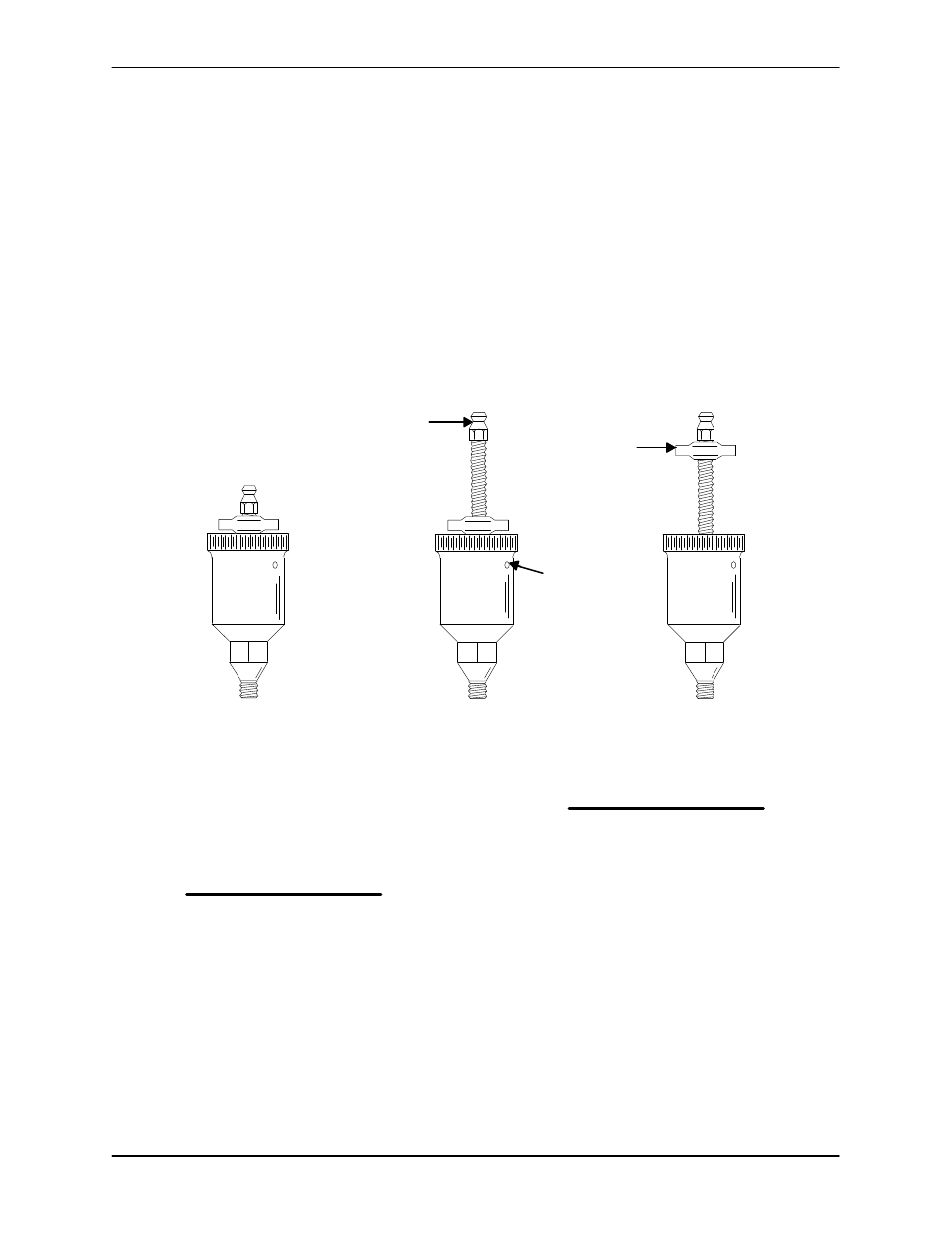

Fill the grease cup (11) through the grease fitting

with No. 2 lithium base grease until grease es-

capes from the relief hole. Turn the grease cup arm

counterclockwise until it is at the top of the stem;

this will release the spring to apply grease to the

seal (see Figure 4).

GREASE

FITTING

CROSS

ARM

POSITION

WHEN

EMPTY

POSITION

FOR

FILLING

POSITION

WHEN

IN USE

RELIEF

HOLE

Figure 4. Automatic Lubricating Grease Cup

NOTE

Some smoking and leakage may occur after instal-

ling a new seal assembly. This should stop after the

pump has run a while and the lapped seal faces

have seated in.

Bearings

The pedestal was fully lubricated when shipped

from the factory. Check the oil level regularly

through the sight gauge (30) and maintain it at the

middle of the gauge. When lubrication is required,

add SAE No. 30 non-detergent oil through the hole

for the air vent (18). Do not over-lubricate. Over-lu-

brication can cause the bearings to over-heat, re-

sulting in premature bearing failure.

NOTE

The white reflector in the sight gauge must be posi-

tioned horizontally to provide proper drainage.