Automatic air release valve – Gorman-Rupp Pumps 88A52-B 1363098 and up User Manual

Page 12

80 SERIES

OM−00990

PAGE B − 5

INSTALLATION

If the application involves a high discharge

head, gradually close the discharge

throttling valve before stopping the pump.

Bypass Lines

If a system check valve is used due to high dis-

charge head, it may be necessary to vent trapped

air from the top of the pump during the priming

process. This may be accomplished by installing a

bypass line from the top of the pump, back to the

source of liquid. The end of the bypass line must be

submerged. The line must be large enough to pre-

vent clogging, but not so large as to affect pump

discharge capacity.

AUTOMATIC AIR RELEASE VALVE

When properly installed, a Gorman-Rupp Auto-

matic Air Release Valve will permit air to escape

through the bypass line and then close automati-

cally when the pump is fully primed and pumping

at full capacity.

Some leakage (1 to 5 gallons [3.8 to 19

liters] per minute) will occur when the

valve is fully closed. Be sure the bypass

line is directed back to the wet well or

tank to prevent hazardous spills.

Consult the manual accompanying the Air Release

Valve for additional information on valve installation

and performance.

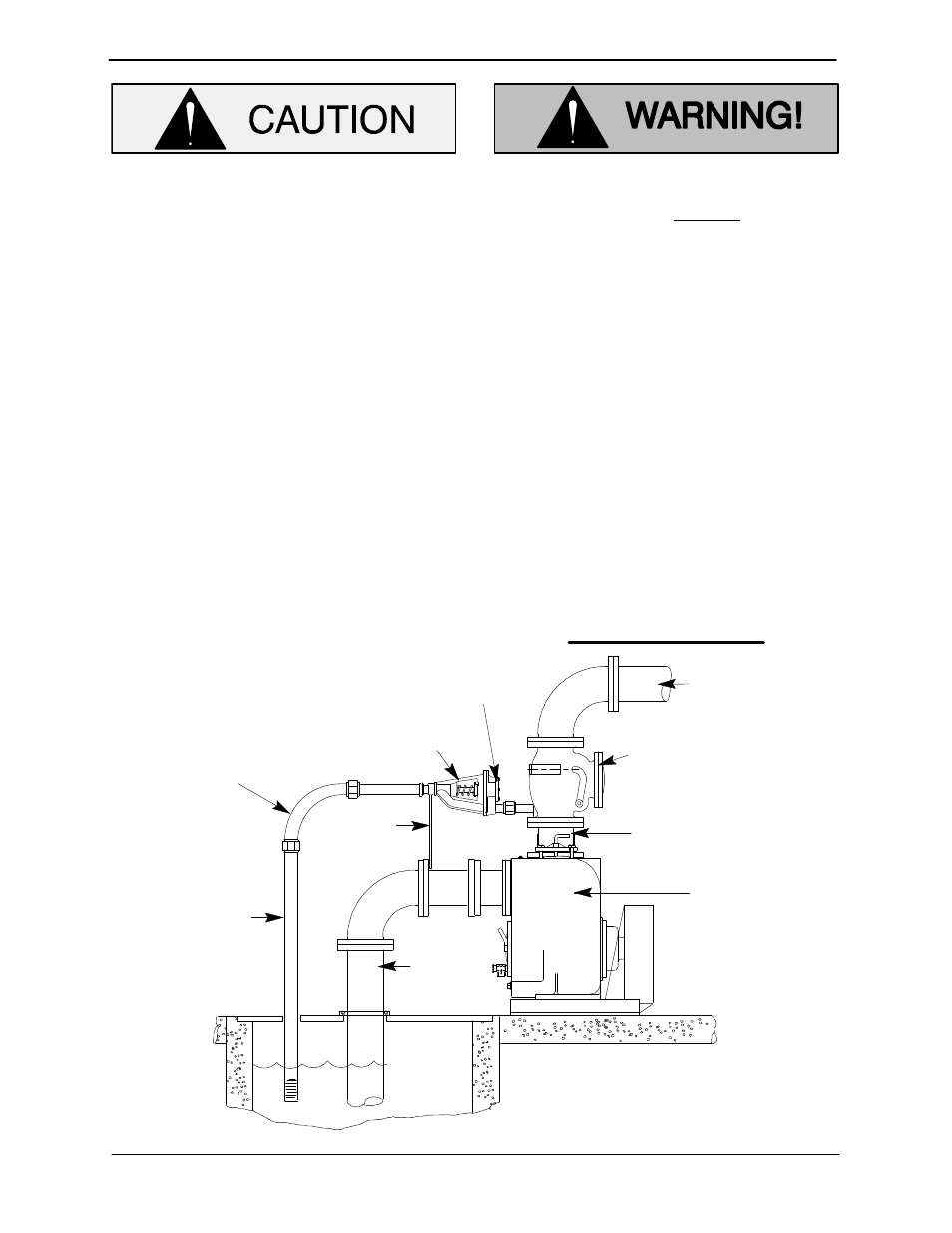

Air Release Valve Installation

The Automatic Air Release Valve must be inde-

pendently mounted in a horizontal position and

connected to the discharge line of the self-priming

centrifugal pump (see Figure 3).

NOTE

If the Air Release Valve is to be installed on a staged

pump application, position the air release valve as

close as possible to the discharge check valve.

DISCHARGE PIPE

DISCHARGE

CHECK VALVE

PUMP DISCHARGE

SELF-PRIMING

CENTRIFUGAL

PUMP

SUCTION

LINE

SUPPORT

BRACKET

CLEAN-OUT

COVER

INSTALL AIR RELEASE VALVE

IN HORIZONTAL POSITION

90

_ LONG

RADIUS

ELBOW

WET WELL

OR SUMP

BLEED LINE 1"

(25,4 MM) DIA. MIN.

(CUSTOMER FUR-

NISHED) EXTEND 6"

(152 MM) BELOW

PUMP OFF LIQUID

LEVEL

Figure 3. Typical Automatic Air Release Valve Installation