Gorman-Rupp Pumps 14A65-B 776101 and up User Manual

Page 32

OM-2151

10 SERIES

MAINTENANCE & REPAIR

PAGE E - 9

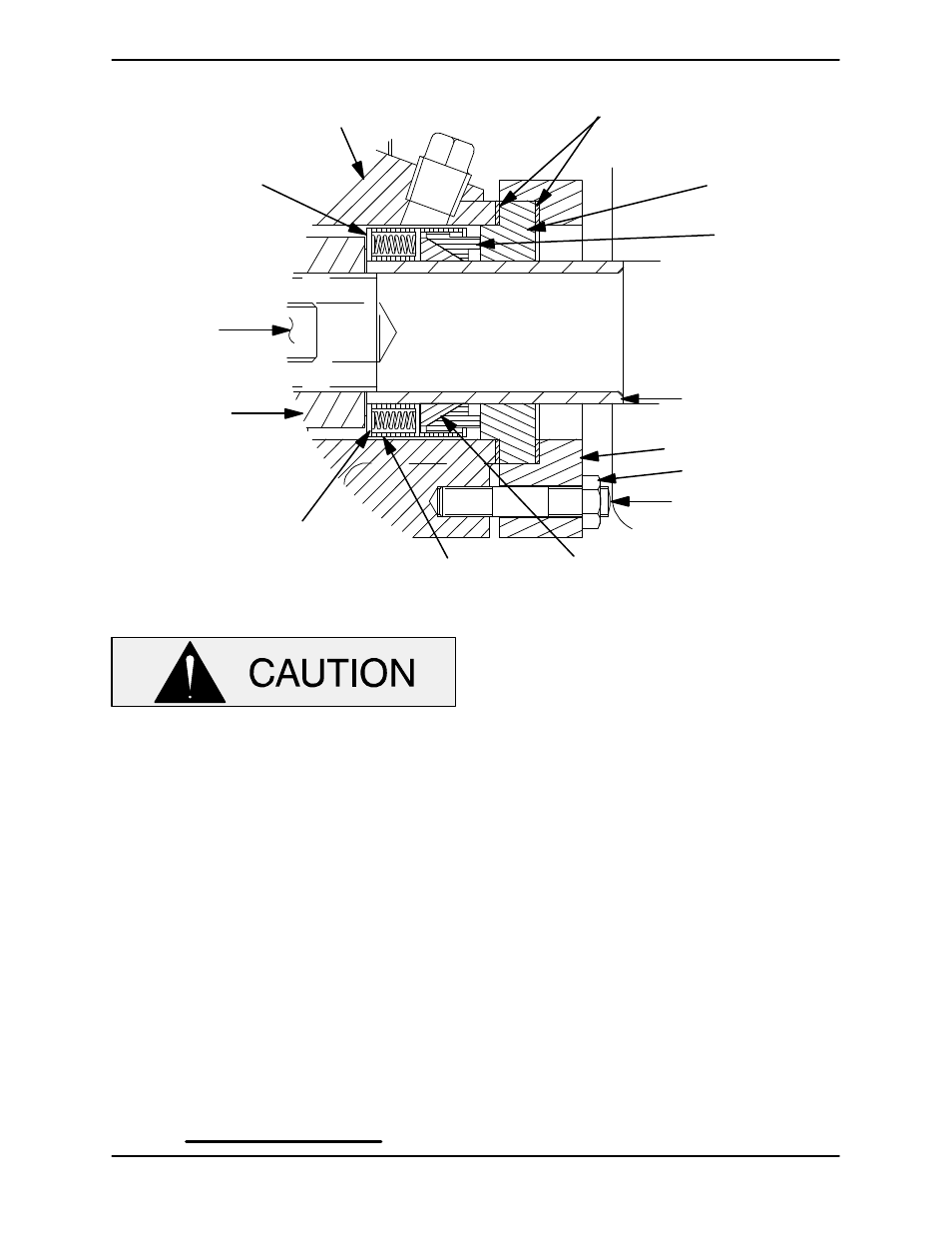

SEAL

PLATE

ROTATING

ELEMENT

STATIONARY

SEAT

SPRING

IMPELLER

SHIMS

IMPELLER

SHAFT

SLEEVE

IMPELLER

SHAFT

RETAINER

SEAL CLAMP

GASKETS

SEAL WEDGE

HEX NUT

STUD

Figure E-3. Seal Assembly

This seal is not designed for operation at

temperatures above 160

_F (71_C). Do not

use at higher operating temperatures.

Inspect the precision finished seal faces to ensure

that they are not damaged or contaminated with

foreign matter.

Position the seal plate (52) on a flat surface with the

impeller side down. Assemble the stationary seat

and gaskets in the seal clamp (15) with the white

gasket toward the seal cavity side of the stationary

seat. Secure the seal cap and stationary seal com

ponents to the seal plate with the nuts (17).

NOTE

The white teflon seat gasket must be installed on

the seal cavity side of the stationary seat. The

'Chemlon' seal wedge should be lightly oiled be

fore installation.

Slide the seal plate over the shaft until fully seated

against the pedestal (22). Be careful not to dam

age the seal stationary seat on the shaft threads.

Align the pipe plug (18) with the pedestal opening

and temporarily secure the seal plate to the pedes

tal using two capscrews and nuts (3/8-16 UNC X

1-1/2 inch long, not supplied).

Slide the rotating portion of the seal onto the lubric

ated shaft sleeve with the seal face toward the

chamfered end of the sleeve. Position the seal re

tainer the same distance from the impeller end of

the sleeve (or scribed line) as noted during disas

sembly.

If a new sleeve is being used, or the correct loca

tion location for the seal is not known, slide the

sleeve onto the shaft until it seats against the shaft

shoulder. Measure 1-1/4 inch (31,7 mm) out from

the stationary seat and mark the sleeve with a felt

tip marker. This is the designed working length of

the seal.

Secure the stationary portion of the seal to the

sleeve at the marked location by tightening the set