Alignment – Gorman-Rupp Pumps 14C20-B 740693 and up User Manual

Page 14

10 SERIES

OM-00680

PAGE B - 7

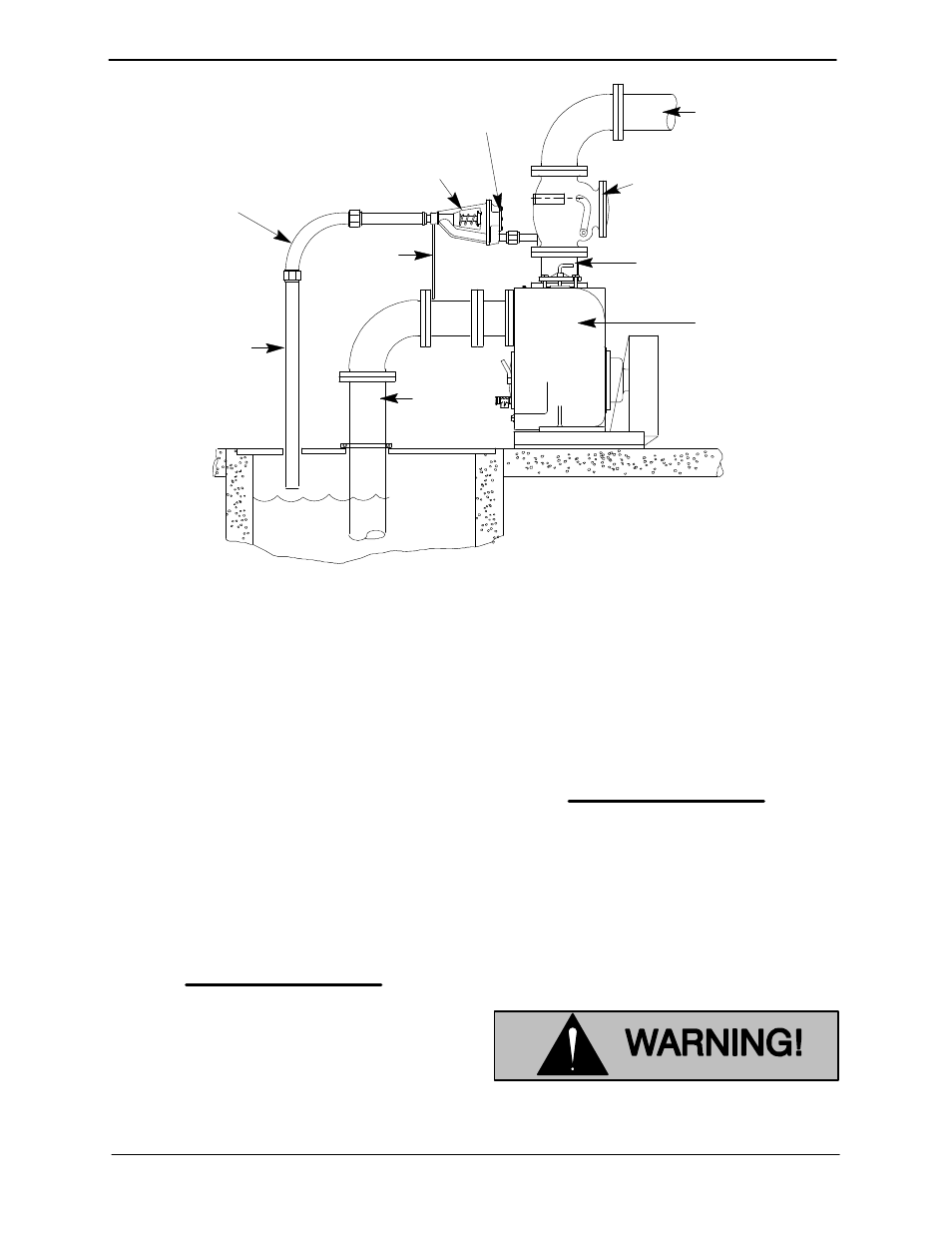

INSTALLATION

DISCHARGE PIPE

DISCHARGE

CHECK VALVE

PUMP DISCHARGE

SELF‐PRIMING

CENTRIFUGAL

PUMP

SUCTION

LINE

SUPPORT

BRACKET

CLEAN‐OUT

COVER

INSTALL AIR RELEASE VALVE

IN HORIZONTAL POSITION

90

_ LONG

RADIUS

ELBOW

WET WELL

OR SUMP

BLEED LINE 1”

(25,4 MM) DIA. MIN.

(CUSTOMER FUR

NISHED) DO NOT EX

TEND BELOW PUMP

OFF LIQUID LEVEL

Figure 3. Typical Automatic Air Release Valve Installation

Connect the valve outlet to a bleed line which

slopes back to the wet well or sump. The bleed line

must be the same size as the outlet opening or

larger, depending on which Air Release Valve is be

ing used. If piping is used for the bleed line, avoid

the use of elbows whenever possible.

NOTE

For multiple pump installations, it is recommended

that each Air Release Valve be fitted with an inde

pendent bleeder line directed back to the wet well.

If multiple Air Release Valves are installed in a sys

tem, do not direct bleeder lines to a common mani

fold pipe. Contact your Gorman‐Rupp distributor or

the Gorman‐Rupp Company for information about

installation of an Automatic Air Release Valve for

your specific application.

ALIGNMENT

The alignment of the pump and its power source is

critical for trouble‐free mechanical operation. In

either a flexible coupling or V‐belt driven system,

the driver and pump must be mounted so that their

shafts are aligned with and parallel to each other. It

is imperative that alignment be checked after the

pump and piping are installed, and before opera

tion.

NOTE

Check Rotation, Section C, before final alignment

of the pump.

When mounted at the Gorman‐Rupp factory, driver

and pump are aligned before shipment. Misalign

ment will occur in transit and handling. Pumps

must be checked and realigned before operation.

Before checking alignment, tighten the foundation

bolts. The pump casing feet and/or pedestal feet,

and the driver mounting bolts should also be tightly

secured.

When checking alignment, disconnect

the power source to ensure that the

pump will remain inoperative.