Lubrication – Gorman-Rupp Pumps 11 1/2A2-B 347543 and up User Manual

Page 34

OM-00558

10 SERIES

MAINTENANCE & REPAIR

PAGE E - 11

LUBRICATION

Seal Assembly

(Figures 1 and 4)

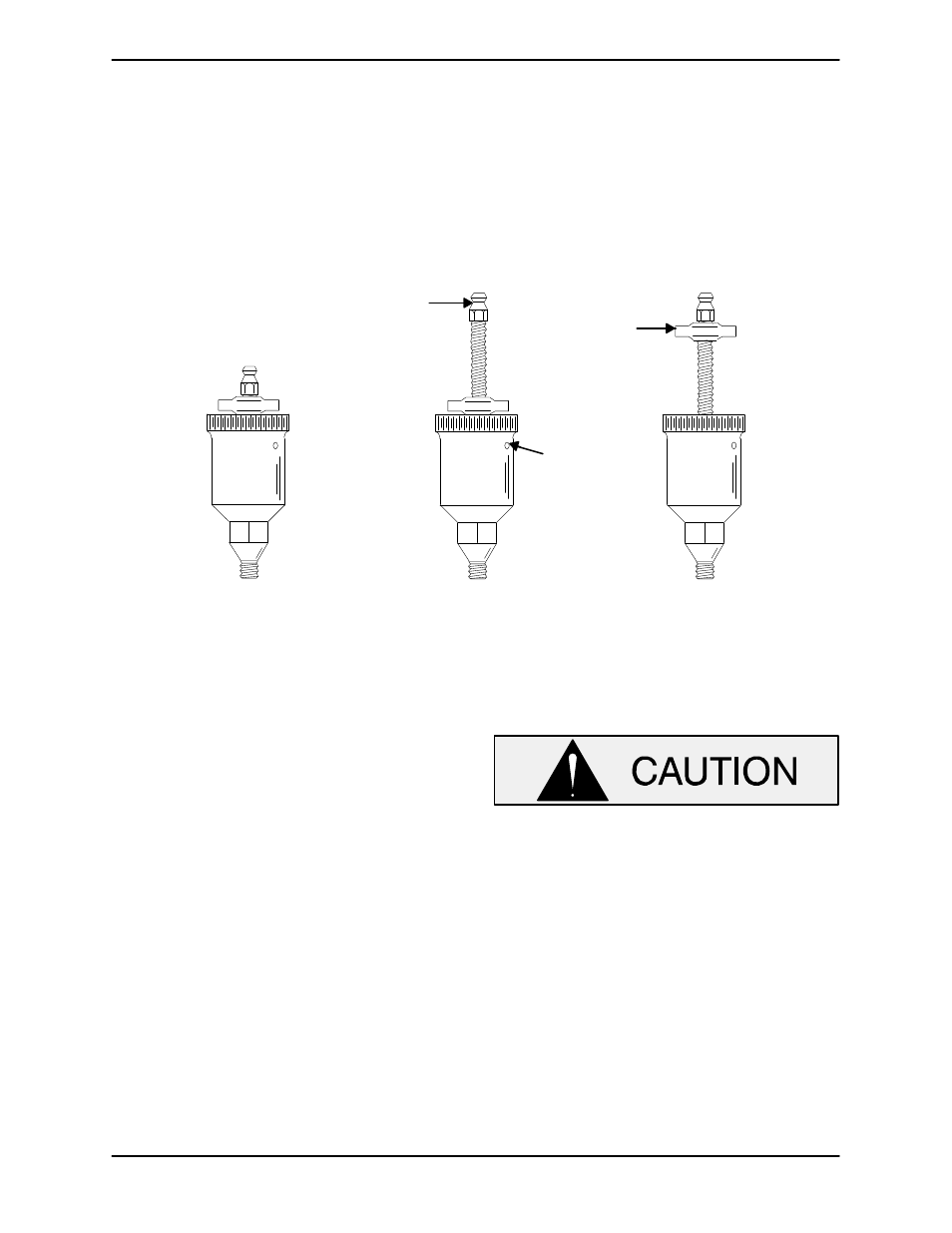

Fill the grease cup (12) through the grease fitting

with No. 2 lithium base grease until grease es

capes from the relief hole. Turn the grease cup arm

counterclockwise until it is at the top of the stem;

this will release the spring to apply grease to the

seal (see Figure 4).

GREASE

FITTING

CROSS

ARM

POSITION

WHEN

EMPTY

POSITION

FOR

FILLING

POSITION

WHEN

IN USE

RELIEF

HOLE

Figure 4. Automatic Lubricating Grease Cup

Bearings

The pedestal was fully lubricated when shipped

from the factory. Under normal conditions, remove

the vented plug (18) and add one shot of No. 0 lithi

um base grease from a grease gun after each 250

hours of operation or once each month, whichever

comes first. Do not over lubricate. Over lubrication

can cause the bearings to over heat, resulting in

premature bearing failure.

There are no provisions in the bearing cavity to

drain or flush the lubricant. The pump and pedestal

must be disassembled to completely clean and

maintain this cavity.

Under normal conditions, change the grease after

each 5000 hours of operation, or at 12 month inter

vals, whichever comes first. Change the grease

more frequently if the pump is operated continu

ously or installed in an environment where variable

hot and cold temperatures are common.

When lubricating a dry (overhauled) pedestal, fill

the cavity with approximately 1.5 ounces (43

grams) of grease.

Monitor the condition of the bearing lubri

cant regularly for evidence of rust or mois

ture condensation. This is especially im

portant in areas where variable hot and

cold temperatures are common.

Power Source

Consult the literature supplied with the power

source, or contact your local power source repre

sentative.