Gorman-Rupp Pumps 11 1/2A9-B 376069 and up User Manual

Page 32

OM-00570

10 SERIES

MAINTENANCE & REPAIR

PAGE E - 9

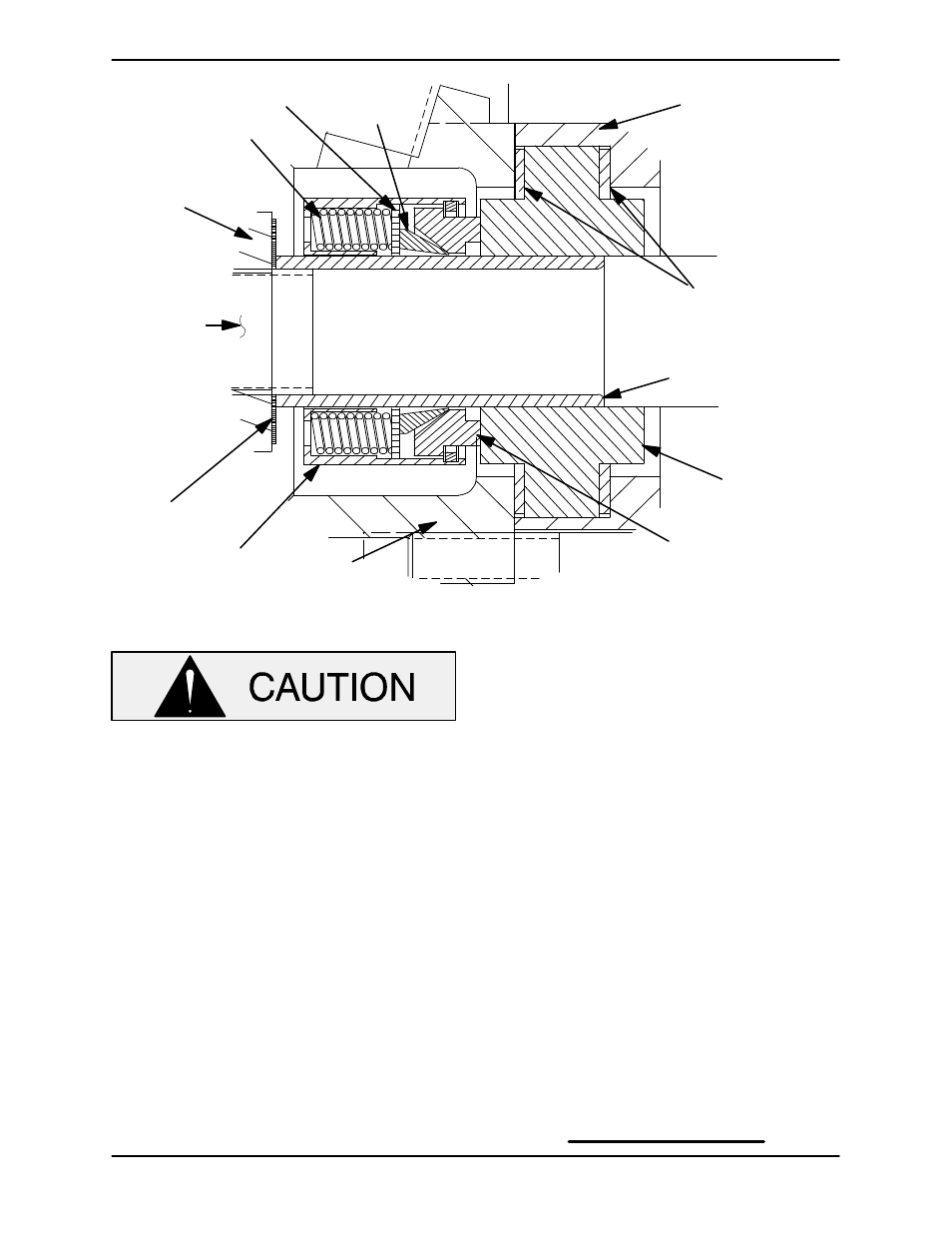

SEAL CLAMP

IMPELLER

SHAFT

STATIONARY

SEAT

ROTATING

ELEMENT

IMPELLER

SHIMS

IMPELLER

SPRING

SHAFT

SLEEVE

RETAINER

GASKETS

SEALING

WEDGE

DISC

SEAL PLATE

Figure 3. Seal Assembly

This seal is not designed for operation at

temperatures above 160

_F (71_C). Do not

use at higher operating temperatures.

Position the seal plate (34) on a flat surface with the

impeller side down. Assemble the stationary seat

and gaskets in the seal clamp (31) with the white

gasket toward the seal cavity side of the stationary

seat. Secure the seal cap and stationary seal com

ponents to the seal plate with the capscrews (30).

Slide the seal plate over the shaft until fully seated

against the pedestal (16). Be careful not to dam

age the seal stationary seat on the shaft threads.

Align the pipe plug (12) with the pedestal opening

and temporarily secure the seal plate to the pedes

tal using two capscrews and nuts (3/8‐16 UNC X 1

1/2 inch long, not supplied).

Slide the rotating portion of the seal onto the lubri

cated shaft sleeve to the dimension (or scribed

line) noted during disassembly. Secure the station

ary portion of the seal to the sleeve by tightening

the setscrews in the seal retainer.

Slide the sleeve and rotating portion of the seal

onto the shaft until the seal elements contact.

Impeller Installation And Adjustment

Inspect the impeller, and replace it if cracked or

badly worn. Install the same thickness of impeller

shims (10) as previously removed, and screw the

impeller onto the shaft until tight.

A clearance of .010 to .012 inch (0,25 to 0,30 mm)

between the impeller and the seal plate is neces

sary for maximum pump efficiency. Measure this

clearance and add or remove impeller shims until

this clearance is reached.

NOTE

Be sure the seal plate is tight against the pedestal

while measuring this clearance.