Gorman-Rupp Pumps 12B65-B 776101 and up User Manual

Page 28

OM-02149

10 SERIES

MAINTENANCE & REPAIR

PAGE E - 5

Pump Casing Removal

Death or serious personal injury and

damage to the pump or components

can occur if proper lifting procedures

are not observed. Make certain that

hoists, chains, slings or cables are in

good working condition and of suffi

cient capacity and that they are posi

tioned so that loads will be balanced

and the pump or components will not be

damaged when lifting. Suction and dis

charge hoses and piping must be re

moved from the pump before lifting. Lift

the pump or component only as high as

necessary and keep personnel away

from suspended objects.

To service the impeller or seal assembly, discon

nect the discharge piping. Remove the hardware

securing the pump to the base.

Remove the nuts (34) and separate the pump cas

ing and gasket set (36) from the seal plate (35) and

pedestal (25). Tie and tag any leveling shims used

under the pump mounting feet to ease reassembly.

Remove the gasket set. Tie and tag the gaskets, or

measure and record their thickness for ease of

reassembly. Clean the mating surfaces of the seal

plate and pump casing.

Impeller Removal

Disconnect the power source.

Immobilize the impeller by wedging a block of

wood between the vanes. If removed, install the

shaft key (20). Install a lathe dog on the drive end of

the shaft (22) with the “V” notch positioned over the

shaft keyway.

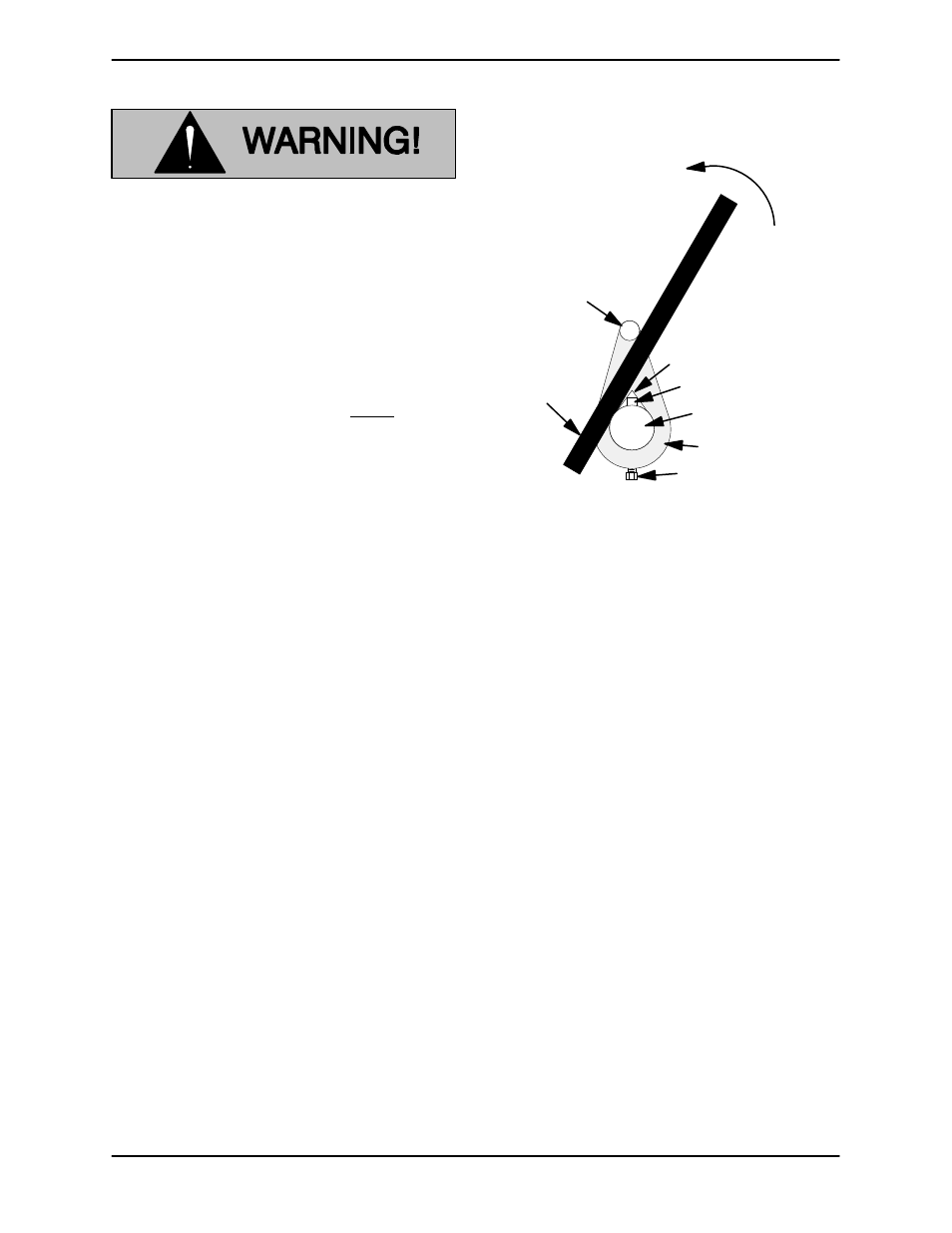

With the impeller rotation still blocked, strike the

lathe dog sharply in a counterclockwise direction

(when facing the drive end of the shaft). The impel

ler may also be loosened by using a long piece of

heavy bar stock to pry against the arm of the lathe

dog in a counterclockwise direction (when facing

the drive end of the shaft) as shown in Figure 2.

Use caution not to damage the shaft or keyway.

When the impeller breaks loose, remove the lathe

dog and wood block and unscrew the impeller

from the shaft.

Turn

Counterclockwise

Lathe Dog Arm

“V” Notch

Shaft Key

Impeller Shaft

Lathe Dog

Setscrew

Heavy

Bar Stock

Figure 2. Loosening Impeller

Unscrew the impeller in a counterclockwise direc

tion.

Inspect the impeller and replace it if cracked or

badly worn. Slide the impeller adjusting shims (9)

off the impeller shaft. Tie and tag the shims or mea

sure and record their thickness for ease of reas

sembly.

Seal Removal and Disassembly

Slide the shaft sleeve (12) and rotating portion of

the seal off the shaft as a single unit. Measure and

record the distance from the impeller end of the

sleeve to the end of the seal retainer, or use a felt‐tip

marker to scribe a line on the sleeve at this location.

Loosen the setscrews securing the retainer to the

sleeve and slide the rotating portion of the seal off

the sleeve.

Slide the seal plate and stationary seal compo

nents off the shaft as a single unit. Place the seal

plate on a flat surface with the impeller side down.

Remove the nuts (32) and separate the seal clamp

(11) and stationary portion of the seal from the seal

plate. Remove the stationary portion of the seal

from the seal clamp.

If no further disassembly is required, see Seal

Reassembly and Installation.