Gorman-Rupp Pumps 112E60-B 1408480 and up User Manual

Page 31

OM-00905

10 SERIES

MAINTENANCE & REPAIR

PAGE E - 9

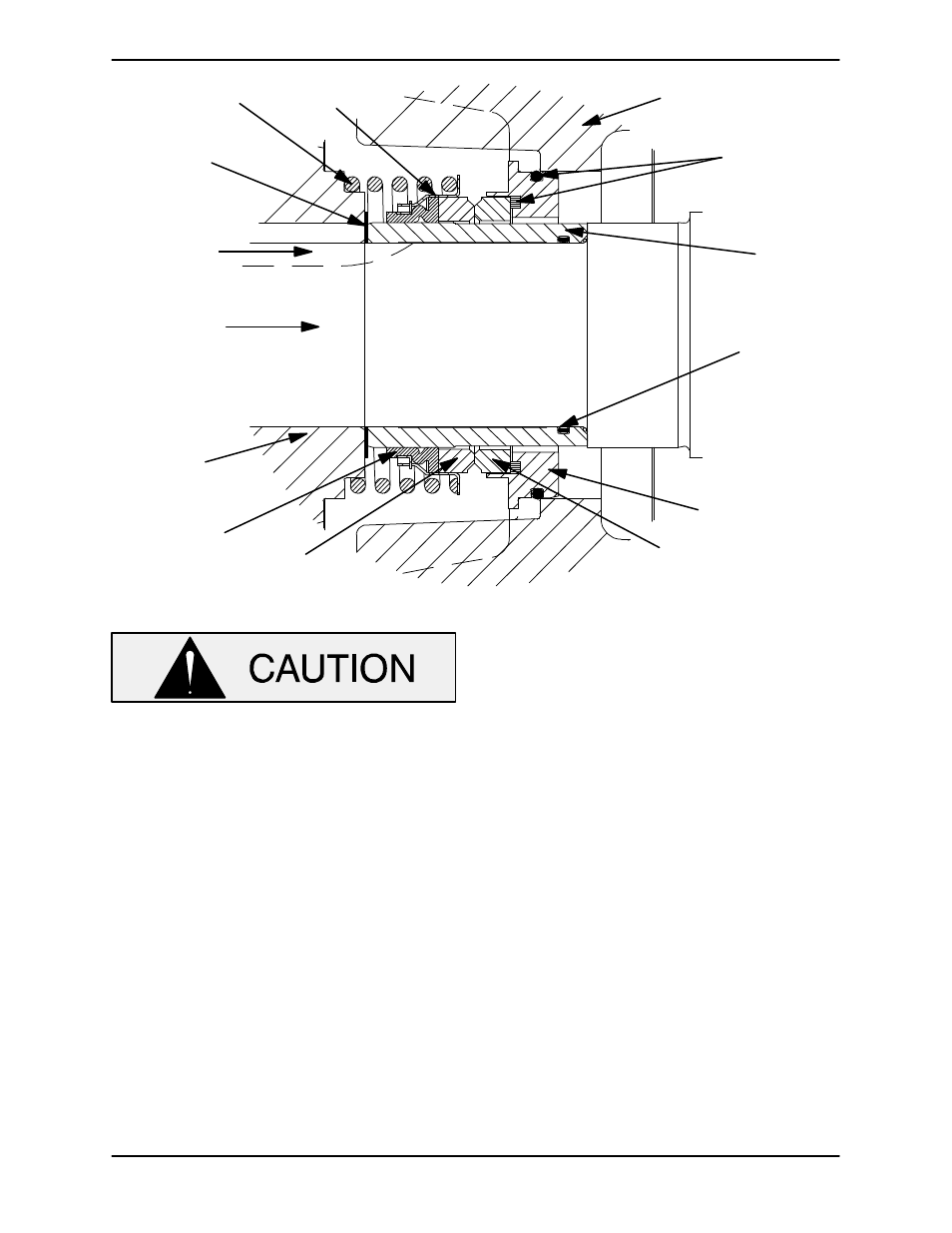

IMPELLER

SHAFT

IMPELLER

SHAFT

SLEEVE

RETAINER

ROTATING

ELEMENT

STATIONARY

ELEMENT

SPRING

SEAL PLATE

STATIONARY

SEAT

SHAFT

SLEEVE

O‐RING

O‐RINGS

BELLOWS

IMPELLER

SHIMS

SHAFT

KEY

Figure E-2. 46512-259 Seal Assembly

This seal is not designed for operation at

temperatures above 160

_F (71_C). Do not

use at higher operating temperatures.

Lubricate the O‐rings (22 and 53) with a small

amount of grease and install them on the seal plate

(56).

Position the seal plate on a flat surface with the im

peller side up. Press the stationary subassembly

(consisting of the stationary seat, O‐rings and sta

tionary element) into the seal plate until the station

ary seat bottoms against the seal plate bore.

Slide the seal plate onto the shaft and secure it to

the pedestal with the hardware (24 and 25).

Lubricate and install the O‐ring in the groove in the

I.D. of the shaft sleeve (31). Lubricate the shaft

sleeve and slide the rotating subassembly (con

sisting of the rotating element, retainer and bel

lows) onto the sleeve until the rotating element is

just flush with the chamfered end of the shaft.

Slide the sleeve and rotating subassembly onto

the shaft until the seal faces contact. Use caution

to ensure that the shaft sleeve O‐ring is not cut or

damaged on the impeller keyway. Continue to

push the sleeve through the seal until it bottoms

against the shaft shoulder. Install the seal spring.

Lubricate the seal assembly as indicated in

LUBRICATION, after the impeller has been in

stalled.

Impeller Installation And Adjustment

Inspect the impeller, and replace it if cracked or

badly worn. Install the same thickness of impeller

adjusting shims as previously removed, and install

the impeller key (81). Apply a thin, uniform coat of

“Never‐Seez” or equivalent compound to the shaft

area under the impeller and press the impeller onto

the shaft until fully seated. Make sure the seal

spring is squarely seated over the step on the back

of the impeller.

A clearance of .010 to .020 inch (0,25 to 0,51 mm)

is required between the impeller and seal plate to