Gorman-Rupp Pumps 14C20-4024T 1303140 and up User Manual

Page 35

OM−05781

10 SERIES

MAINTENANCE & REPAIR

PAGE E − 13

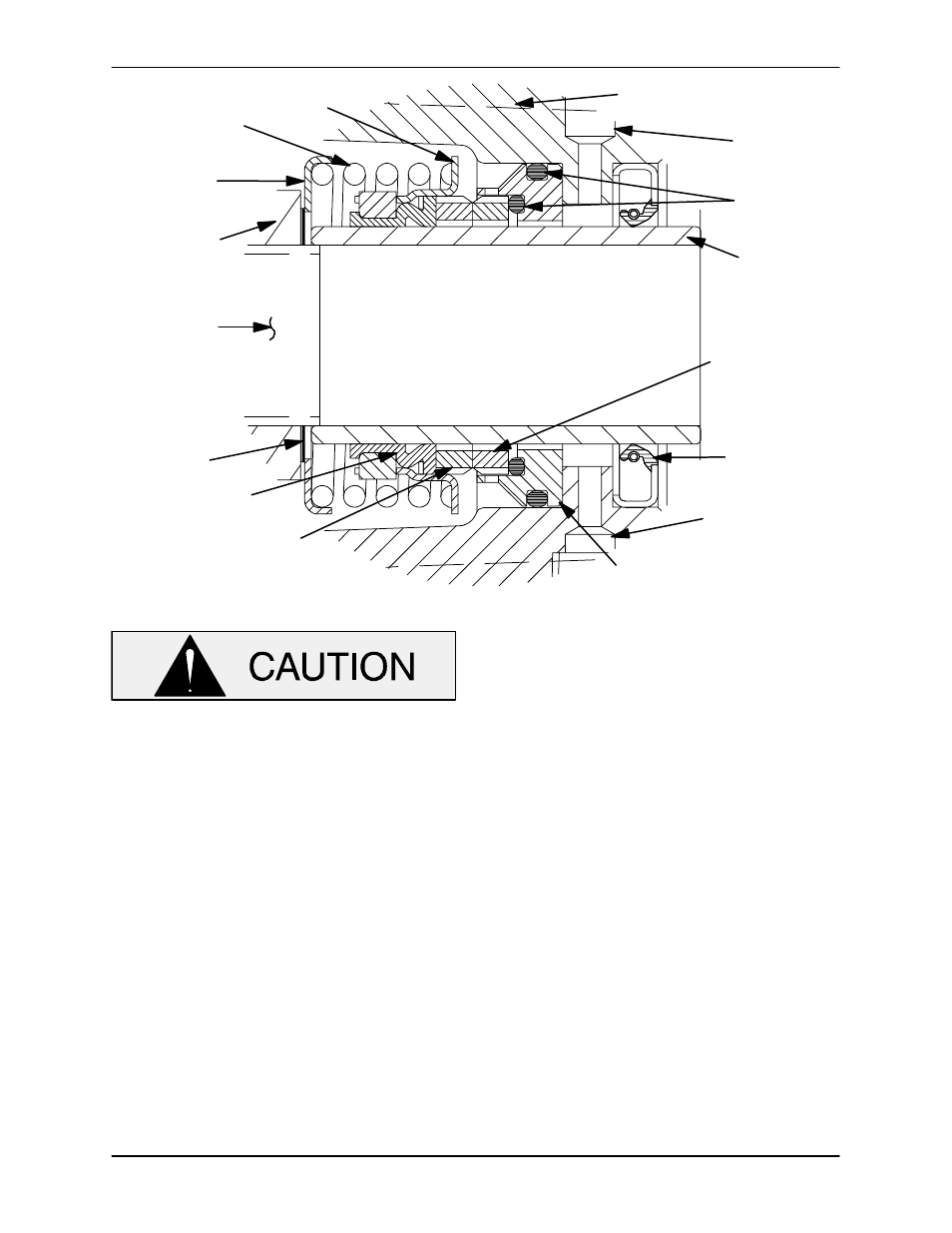

SEAL PLATE

O-RINGS

IMPELLER

OIL SEAL

STATIONARY SEAT

STATIONARY

ELEMENT

ROTATING ELEMENT

BELLOWS

IMPELLER

SHIMS

IMPELLER

SPRING

RETAINER

SHAFT

SHAFT

SLEEVE

BOTTLE

OILER

SPRING

HOLDER

DRAIN PLUG

Figure E−5. 12364D Seal Assembly

This seal is not designed for operation at

temperatures above 160

_F (71_C). Do not

use at higher operating temperatures.

Inspect the seal plate (35) and the impeller shaft

(26) for burrs or sharp corners, and remove any

that exist. Install the oil seal (16) in the bore of the

seal plate with the lip positioned as shown in Figure

E−2. Make sure the oil seal is fully seated.

Position the seal plate against the intermediate. Be

careful not to damage the oil seal lip on the shaft

threads. Align the bottle oiler hole with the opening

in the intermediate, and secure the seal plate to the

intermediate with hardware (36 and 37).

Lubricate the stationary seat O-ring with light oil

and press the assembled stationary seat and sta-

tionary element into the seal plate bore until fully

seated. A push tube cut from a length of plastic

pipe would aid this installation. The I.D. of the tube

should be approximately the same as the I.D. of the

seal spring.

Subassemble the stationary and rotating element

into the retainer and bellows. Apply a drop of light

oil on the precision finished faces; never use

grease. Use even pressure to carefully press this

subassembly onto the sleeve (75) with the rotating

element facing the chamfered end of the sleeve.

Position the sleeve on the shaft with the chamfered

end toward the seal cavity. Slide the sleeve onto

the shaft until it seats against the shaft shoulder.

Install the seal spring and spring holder.

Reinstall the bottle oiler and piping (13, 14 and 15).

Lubricate the seal as indicated in LUBRICATION,

after the impeller has been installed.

Impeller Installation And Adjustment

(Figure E−2)

Inspect the impeller, and replace it if cracked or

badly worn.