Gorman-Rupp Pumps 14D2-12LD477 S/G 1348079 and up User Manual

Page 30

10 SERIES

OM−05967

MAINTENANCE & REPAIR

PAGE E − 12

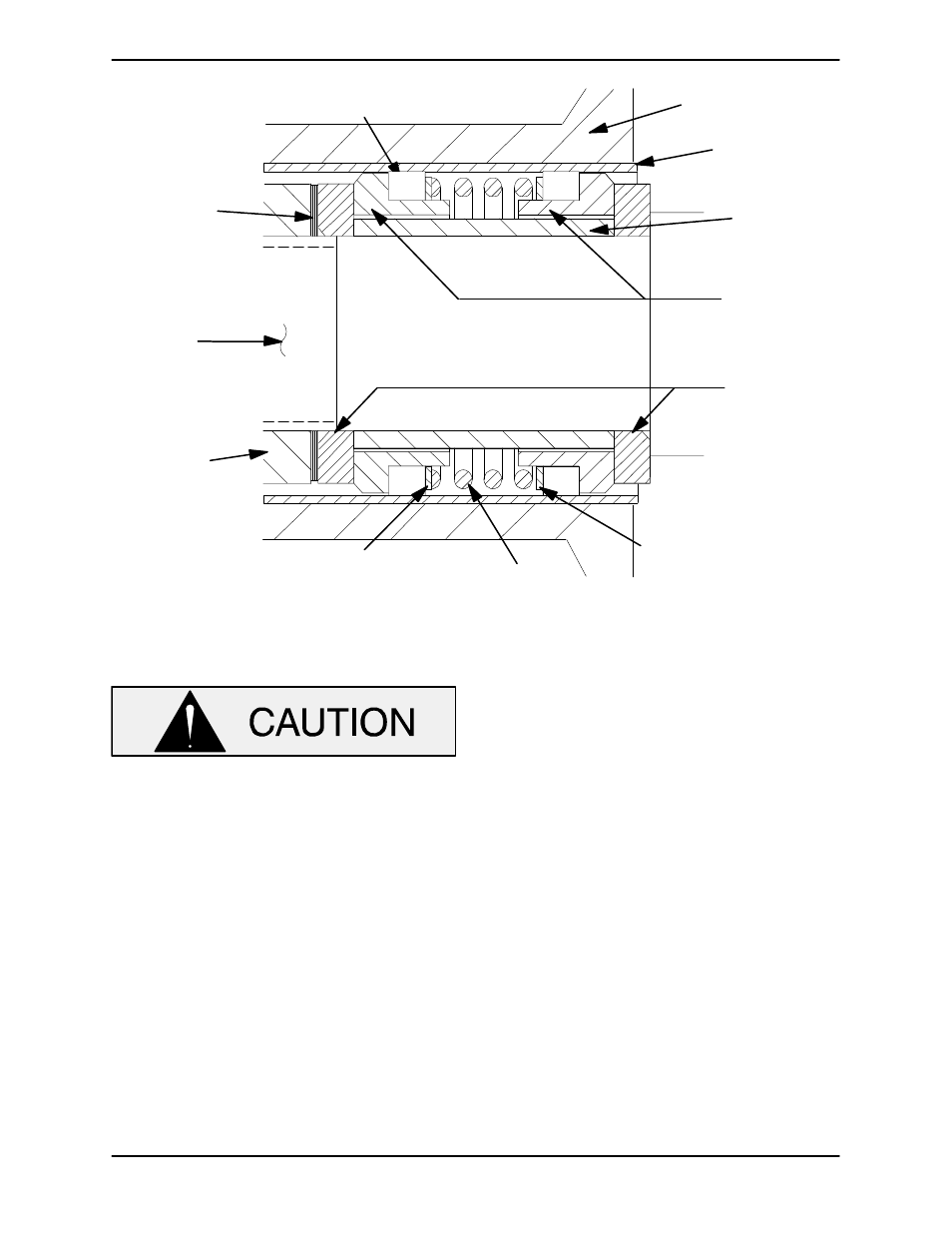

STUB

SHAFT

SEAL

LINER

IMPELLER

IMPELLER

SHIMS

SPACER

SLEEVE

PACKING RINGS

WASHER

STATIONARY

ROTATING

ELEMENTS

STATIONARY

SPRING

SEAL SEATS

INTERMEDIATE

ННН

ННН

ННН

ННН

НН

НН

WASHER

НН

НН

STATIONARY

Figure 5. GS1000C Seal Assembly

This seal is not designed for operation at

temperatures above 110

_F (43_C). Do not

use at higher operating temperatures.

Position the inboard rotating element on the shaft

with the chamfered side toward the shaft shoul-

der and slide it on until fully seated.

Subassemble the inboard stationary seat, packing

ring and stationary washer. Press this unit into the

lubricated seal liner until the seal faces contact. A

push tube cut from a length of plastic pipe would

aid this installation. The I.D. of the tube should be

approximately the same size as the I.D. of the seal

spring.

Install the spacer sleeve and seal spring.

Subassemble the outboard stationary seat, pack-

ing ring and stationary washer. Press this unit into

the lubricated seal liner. Install the outboard rotat-

ing element with the chamfered side toward the

impeller.

After the impeller and grease cup have been in-

stalled, lubricate the seal as indicated in LUBRI-

CATION at the end of this section.

Impeller Installation And Adjustment

(Figure 3)

Inspect the impeller, and replace it if cracked or

badly worn. Install the same thickness of impeller

shims (23) as previously removed, and screw the

impeller onto the shaft until tight.

A clearance of .020 to .040 inch (0,51 to 1,02 mm)

between the impeller and the intermediate is nec-

essary for maximum pump efficiency. Measure this

clearance and add or remove impeller shims until

this clearance is reached.