Gorman-Rupp Pumps 06D17-GAR 1009424 and up User Manual

Page 31

OM−01274

0 SERIES

MAINTENANCE & REPAIR

PAGE E − 11

oil and the container must be absolutely clean. If

the oil has been previously used, it must be thor-

oughly filtered.

Position the intermediate (31) over the shaft (46)

before installing the inboard pinion shaft bearing

(35) as described below.

NOTE

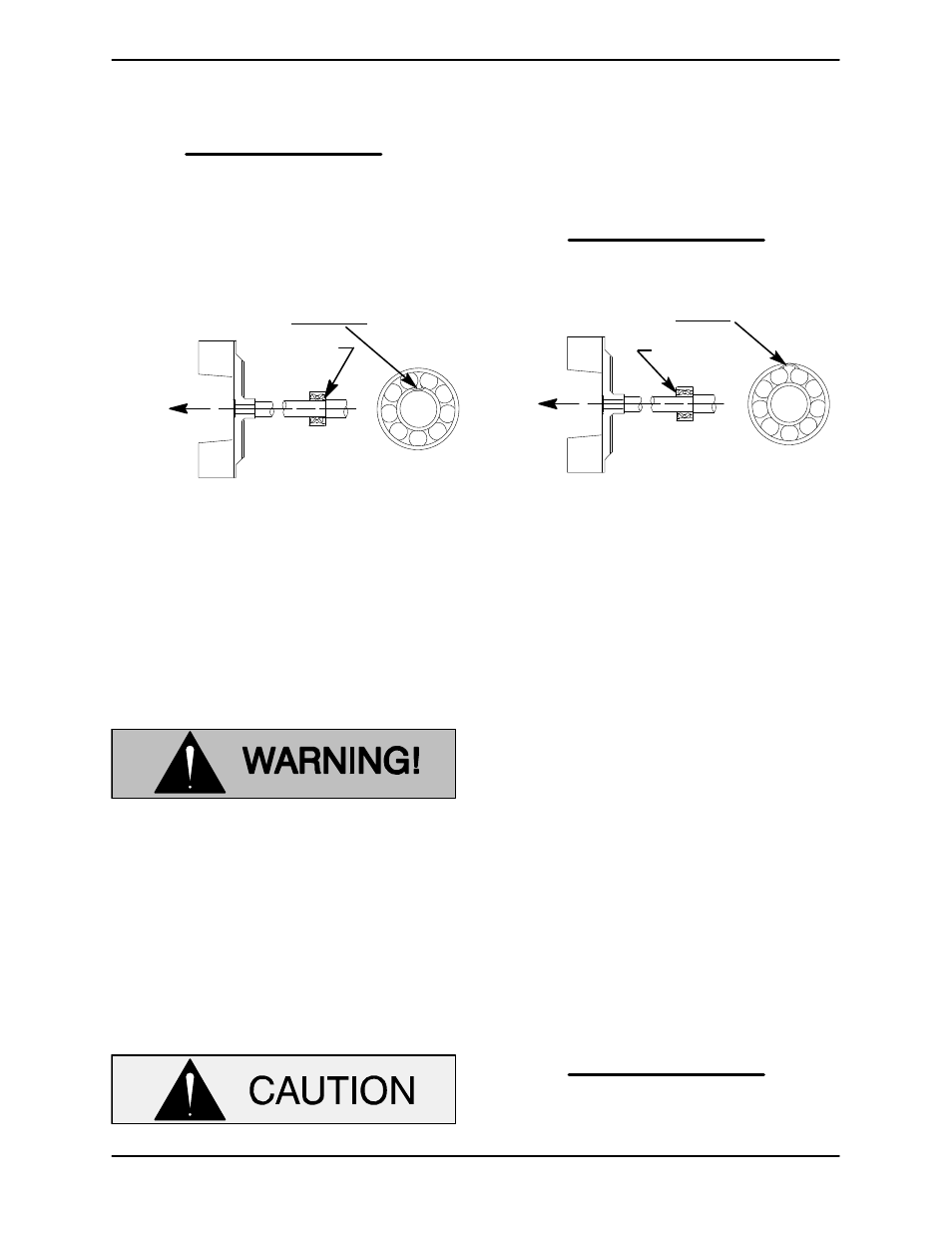

The outboard pinion shaft bearing (35) may be

manufactured with a ball loading groove. Check the

bearing for a loading groove and its conainer for the

name of the manufacturer. When installed on the

shaft, the loading groove (if equipped) must face

the direction shown in Figure 5.

INSTALLATION OF FEDERAL MOGAL 5300W

OR NTN 3300 SERIES BEARINGS

(OPEN OR ENCLOSED IMPELLERS)

INSTALLATION OF MRC/SKF 5300M, 5300E OR

TIMKEN 5300W SERIES BEARINGS

(OPEN OR ENCLOSED IMPELLERS)

LOADING

DIRECTION OF

THRUST

BALL LOADING

GROOVE POSITIONED

AWAY FROM IMPELLER

GROOVE

DIRECTION OF

THRUST

LOADING

BALL LOADING

GROOVE POSITIONED

TOWARD IMPELLER

GROOVE

Figure 5. Bearing Positioning

Heat the bearings to a uniform temperature no

higher than 250

_F (120_C) and slide them onto

the shafts, one at a time, until they are fully seated.

This should be done quickly, in one continuous

motion, to prevent the bearings from cooling and

sticking on the shaft.

Use caution when handling hot bear-

ings to prevent burns.

After the bearings have been installed and allowed

to cool, check to ensure that they have not moved

out of position in shrinking. If movement has oc-

curred, use a suitably sized sleeve and a press to

reposition the bearings.

If heating the bearings is not practical, use a suit-

ably sized sleeve and an arbor (or hydraulic) press

to install the bearings onto the shafts.

When installing the bearings onto the

shafts, never press or hit against the outer

race, balls, or ball cage. Press only on the

inner race.

Position the gearbox housing on a flat surface with

the pump side up and support it so it is level and

stable. Install the gasket (34) and slide the as-

sembled pinion shaft, intermediate and bearings

into the gearbox housing until the gear teeth mesh

with those of the helical gear. Slide the intermediate

into the gearbox housing until fully seated.

Continue to slide the pinion shaft and bearing into

the gearbox until the inboard bearing (25) is fully

seated.

NOTE

Pinion shaft endplay should be between .005 and

.012 inch (0,127 to 0,305 mm). Install the same

thickness of bearing shims (36) as previously re-

moved, then reinstall the pump casing (1) as de-

scribed in PUMP AND SEAL REASSEMBLY. Add or

remove bearing shims to achieve the correct

endplay.

Position the gearbox housing on the bed of an ar-

bor (or hydraulic) press with the pump side down,

and support it so it is level and stable. Lubricate the