Gorman-Rupp Pumps T4A60S-F3L 1314225 and up User Manual

Page 43

OM-05512

SUPER T SERIES

MAINTENANCE & REPAIR

PAGE E - 16

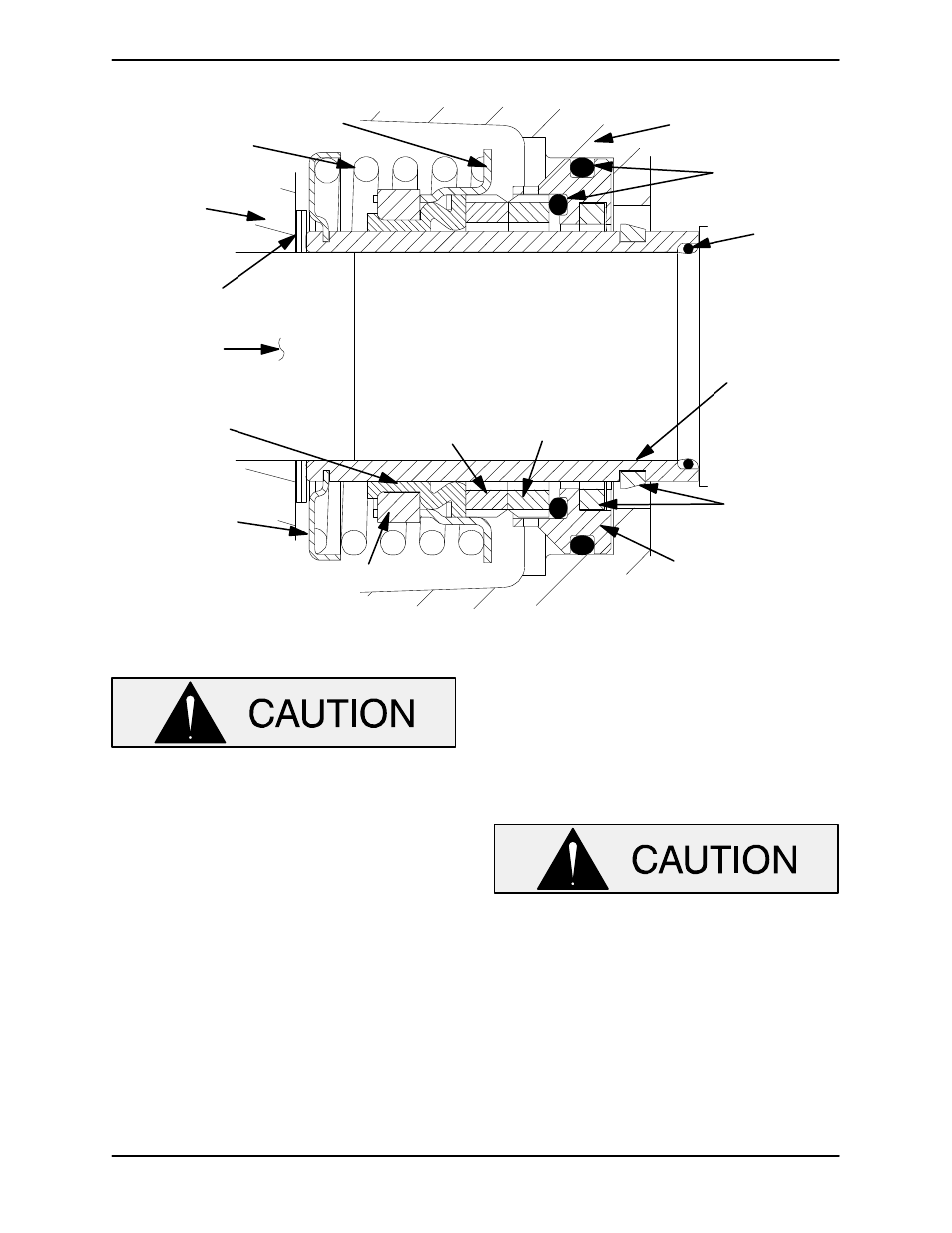

SEAL PLATE

O‐RINGS

IMPELLER

SHAFT

STATIONARY

SEAT

STATIONARY

ELEMENT

ROTATING

ELEMENT

DRIVE BAND

BELLOWS

IMPELLER

SHIMS

IMPELLER

SPRING

RETAINER

INTEGRAL

SHAFT

SLEEVE

SLEEVE

O‐RING

SPRING

CENTERING

WASHER

SHEAR

RING

(SHEARED)

Figure 8. 46513-151 Cartridge Seal Assembly

This seal is not designed for operation at

temperatures above 160

_

F (71

_

C). Do not

use at higher operating temperatures.

If the seal plate (4) was removed, install the seal

plate O‐ring (26) and lubricate it with light grease.

Install the seal plate gasket (5). Position the seal

plate over the shaft and secure it to the bearing

housing with the hardware (7 and 8). Install the

bearing housing O‐ring (28) and lubricate it with

light grease.

To prevent damaging the shaft sleeve O‐ring (32)

on the shaft threads, stretch the O‐ring over a piece

of tubing 1‐1/4 I.D. x 1‐1/2 O.D. x 2‐inches long (32

mm x 38 mm x 51 mm). Slide the tube over the shaft

threads, then slide the O‐ring off the tube and onto

the shaft. Remove the tube, and continue to slide

the O‐ring down the shaft until it seats against the

shaft shoulder.

When installing a new cartridge seal assembly,

remove the seal from the container, and remove

the mylar storage tabs, if so equipped, from be

tween the seal faces.

New cartridge seal assemblies may be

equipped with mylar storage tabs between

the seal faces. If so equipped, these stor

age tabs must be removed before install

ing the seal.

Lubricate the external stationary seat O‐ring with

light oil. Slide the seal assembly onto the shaft until

the external stationary seat O‐ring engages the

bore in the seal plate.

Clean and inspect the impeller as described in Im

peller Installation and Adjustment. Install the full