Gorman-Rupp Pumps T8A60S-F6L 1278434 thru 1318430 User Manual

Page 42

OM−05517

SUPER T SERIES

MAINTENANCE & REPAIR

PAGE E − 13

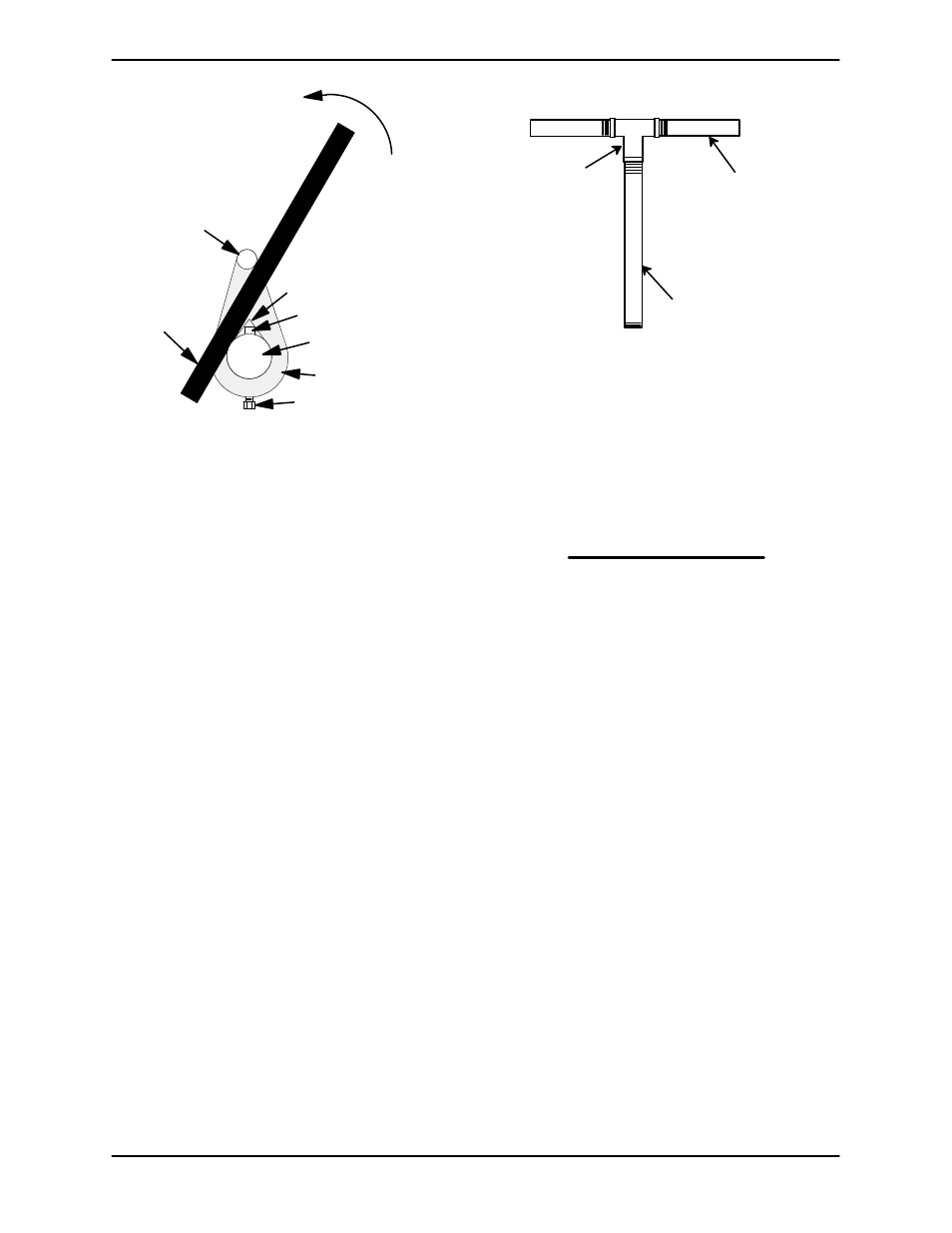

Turn

Counterclockwise

Lathe Dog Arm

V" Notch

Shaft Key

Impeller

Shaft

Lathe Dog

Setscrew

Heavy

Bar Stock

Figure 6. Loosening Impeller

Rotating Assembly Removal

(Figure 3)

Remove the outer hardware (15 and 16) from the

casing ring (14). Install three of the outer cap-

screws in the jacking holes in the casing ring, and

use them to jack the rotating assembly loose from

the pump casing.

After the rotating assembly is loosened, remove

the jacking screws from the casing ring. Remove

the inner hardware (17 and 18) and shims (13).

Separate the casing ring from the pump casing. Tie

and tag the shims for ease of reassembly.

NOTE

An optional disassembly tool is available from the

factory. If the tool is used, follow the instructions

packed with it. A similar tool may be assembled us-

ing 1/2-inch pipe (schedule 80 steel or malleable

iron) and a standard tee (see Figure 7). All threads

are 1/2-inch NPT. Do not pre-assemble the tool.

TEE

APPROX. 6 IN.

(152 MM) LONG

APPROX. 14 IN.

(356 MM) LONG

Figure 7. Rotating Assembly Tool

To install the tool, remove the vented plug (9, Figure

4) from the bearing housing, and screw the longest

length of pipe into the vent hole until fully engaged.

Install the tee, and screw the handles into the tee.

Use caution when lifting the rotating assembly to

avoid injury to personnel or damage to the assem-

bly.

Remove the bearing housing and seal plate O-

rings (32 and 33).

Impeller Removal

(Figure 4)

With the rotating assembly removed from the

pump casing, unscrew the impeller from the shaft.

Use caution when unscrewing the impeller; ten-

sion on the shaft seal spring will be released as the

impeller is removed. Inspect the impeller and re-

place if cracked or badly worn.

Remove the impeller adjusting shims (29); tie and

tag the shims, or measure and record their thick-

ness for ease of reassembly.

Seal Removal

(Figure 4)

Slide the integral shaft sleeve and rotating portion

of the seal off the shaft as a unit.

Use a pair of stiff wires with hooked ends to remove

the stationary element and seat.

An alternate method of removing the stationary

seal components is to remove the hardware (5 and