En 17 troubleshooting – Imetec ZEROCALC ECO K3 2300 User Manual

Page 19

EN

17

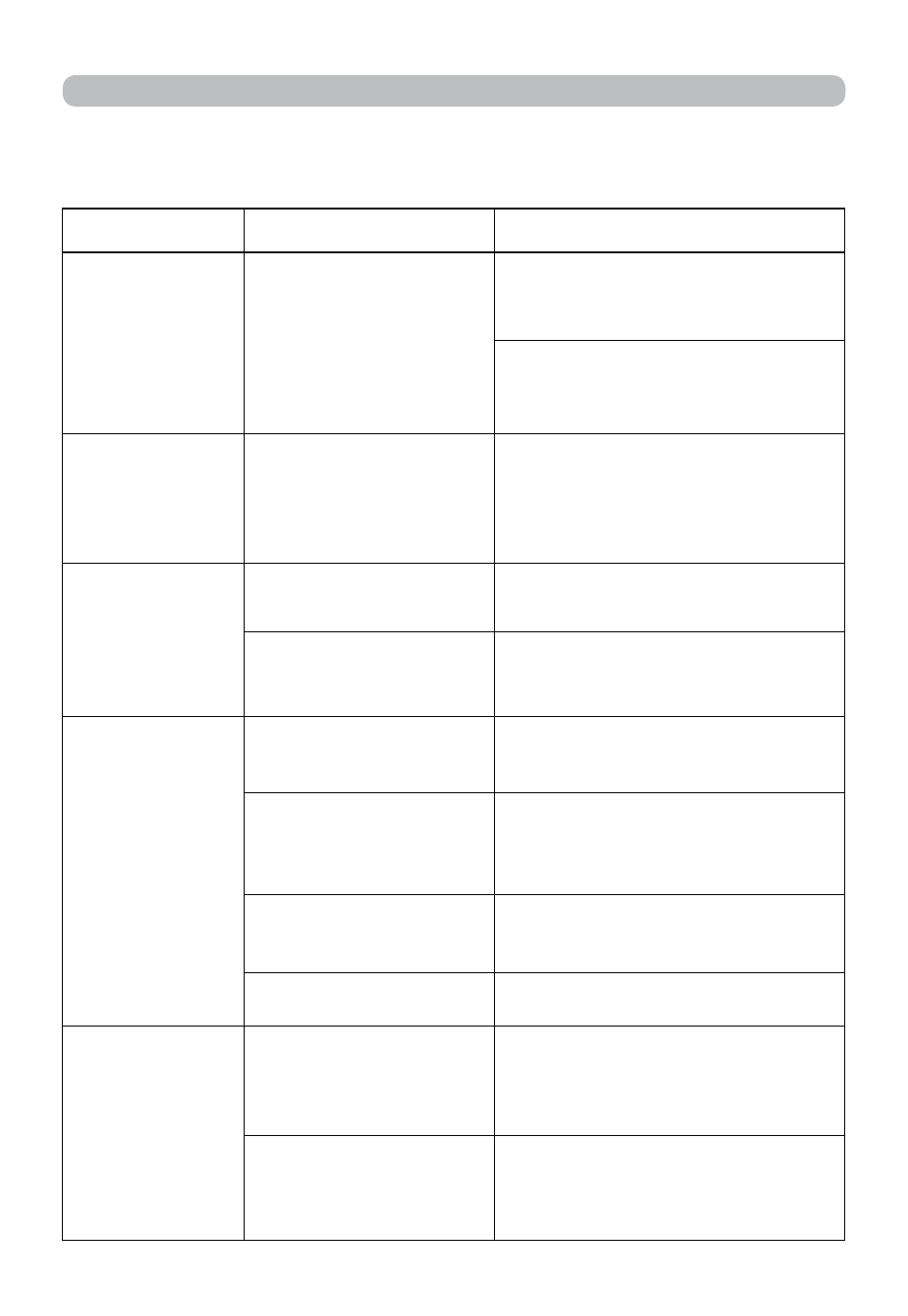

TROUBLESHOOTING

This chapter describes the most common problems that can arise using the appliance. If

the problems cannot be solved with the information below, please contact the Authorised

Assistance Centre.

Problem

Possible cause

Solution

The plate (10)

remains cold or

does not heat up.

There is no power supply.

Verify whether the plug (13) is inserted

correctly or try inserting it in another

socket.

Verify whether the temperature

adjustment knob (2) is set to the

minimum temperature Ø (Fig. D).

The plate

temperature LED

(1) goes on and off.

Normal procedure.

The switching ON and OFF of the LED

indicates the heating phase of the

iron. The LED goes off once the set

temperature is reached.

Only a little steam

or none at all is

dispensed.

The steam selector (5) is

set to Ø.

Set the steam selector (5) to the

desired field (Fig. B).

There is not enough water

in the reservoir (11).

Fill the reservoir (11).

The impurities that

come out from the

steam holes stain

the garments.

Possible residue in the

steam chamber/plate.

Carry out the Self Clean procedure

(see paragraph Seal Clean/Calc-Clean

System).

Chemical additives,

scented liquids or

descaling agents are being

used.

These substances damage the

product: do not add additives to the

water in the reservoir.

Pure distilled water or

softened water is being

used.

Mix tap water (50%) with distilled and/

or demineralised (50%) water.

Starch is being used.

Always spray the starch on the reverse

side of the fabric.

Water leaks from

the plate.

The plate temperature is

too low due to the super-

steam button (4) being

pressed too often.

Allow slightly longer intervals between

the jets of steam.

The temperature

adjustment knob (2) is set

to a temperature that is too

low (Fig. D).

Turn the temperature adjustment knob

(2) to the Max level (Fig. D).