Model lsn – Xylem LSNIH User Manual

Page 22

Installation, Operating and Maintenance Instruction

Model LSN

LSN 100-english

page 20

Revision 01

Article No 771076024

Issue

01/2010

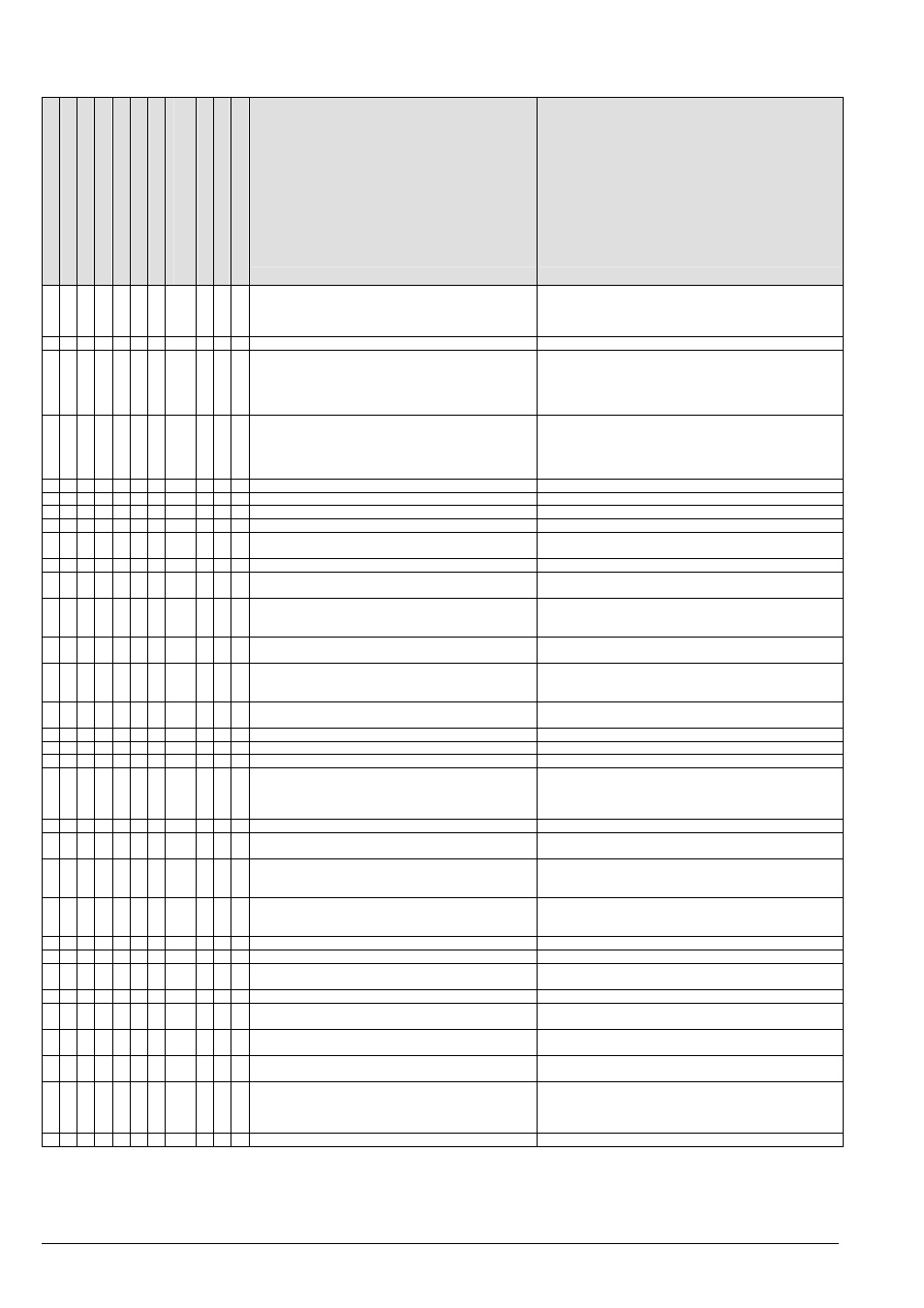

D

is

c

h

a

rg

e

t

o

o

l

o

w

D

is

c

h

a

rg

e

s

to

p

s

a

ft

e

r

a

t

im

e

H

e

a

d

t

o

o

l

o

w

H

e

a

d

t

o

o

h

ig

h

D

ri

v

e

m

e

c

h

a

n

is

m

o

v

e

rl

o

a

d

e

d

P

u

m

p

n

o

t

ru

n

n

in

g

q

u

ie

tl

y

T

e

m

p

e

ra

tu

re

i

n

p

u

m

p

t

o

o

h

ig

h

T

e

m

p

e

ra

tu

re

i

n

s

h

a

ft

s

e

a

lin

g

t

o

o

h

ig

h

T

e

m

p

e

ra

tu

re

a

t

th

e

b

e

a

ri

n

g

t

o

o

h

ig

h

P

u

m

p

l

e

a

k

in

g

L

e

a

k

a

g

e

r

a

te

a

t

s

h

a

ft

s

e

a

lin

g

t

o

o

h

ig

h

Cause

Solution

■

Back-pressure too high

check facility for pollution, open discharge valve

reduce resistance in discharge pipe (e.g. clean filter if

necessary)

use larger impeller (note available motor power)

■

■

■

Back-pressure too low, discharge too low

throttle discharge valve

■ ■

Speed too high

reduce speed

compare speed of motor with specified pump speed (rating

plate)

when adjusting speed (frequency transformer) check refer-

ence value setting

■

■

Speed too low

increase speed (check available motor power)

compare speed of motor with specified pump speed (rating

plate)

when adjusting speed (frequency transformer) check reference

value settings

■ ■

■ ■

Flow too little

increase min. flow (open discharge valve, bypass)

■

Flow too big

reduce flow (throttle discharge valve)

■ ■

Impeller diameter too big

use smaller impeller

■

■

Impeller diameter too small

use larger impeller (check available motor power)

■

■

■ ■

Pump and/or pipes not completely filled with liquid

fill

vent

■ ■ ■

Pump or suction/intake pipe blocked

clean

■

■

Air pocket in pipeline

vent

improve course of pipe

■ ■ ■

■ ■

Suction height too big / NPSH of system too small

increase liquid level and admission pressure

reduce resistance in the intake/suction pipe (change course

and rated width, open shut-off valves, clean filters)

■ ■ ■

Air being sucked in

increase liquid level

check if suction pipe is vacuum-tight

■ ■ ■

Air being sucked in through shaft sealing

clean sealing pipe

increase sealing pressure

replace shaft sealing

■

■

Direction of rotation is wrong

swap over two phases of power supply (to be done by an

electrician)

■

■

■

■

Inner components suffering from wear

replace worn parts

■

■

■

Density and/or viscosity of liquid handled is too high

seek assistance

■

■ Stuffing box not straight

tighten evenly

■

Stuffing box is fastened too tight resp. shaft sealing is worn loosen stuffing box

replace packing and/or mechanical seal

check sealing, flushing and cooling pipes (pressure)

avoid dry running

■

■ Lines and roughness on shaft or shaft sleeve

replace parts

■

■ Unsuitable packing material

use suitable material (check shaft or shaft sleeve for damage

beforehand)

■

■ Deposits on mechanical seal

clean

replace mechanical seal if necessary

if necessary provide additional rinsing or quench

■

■ Impeller out of balance

remove blocks/deposits

replace impeller if broken or unevenly worn

check shafts to ensure that they are running true

■

■

■ Coupling not aligned

align pump unit better

■

■

Coupling distance too small

change

■ ■

■ ■ ■ Forces in pipeline too high (pump unit under strain)

change (support pipes, use compensators, etc.)

is foundation plate/frame properly cast in place?

■

Too much, too little or the wrong type of lubricant

change

■

Electricity supply not right (2-phase running)

check voltage of all phases

check cable connections and fuses

■

Sealing insufficient

tighten screws

replace sealing

■

■

Bearing damaged

replace

check lubricant and bearing space for pollutants (rinse oil area)

■

Relief fittings insufficient

clean relief openings in impeller

replace worn parts (impeller, split rings)

adjust in line with the system pressure/intake pressure given on

ordering

■

System-related vibrations (resonance)

seek assistance