Xylem 501 Electrode Control User Manual

Xylem Equipment

501 Manual

501 Manual

501 Manual

This installation manual applies to:

-209820 501 Electrode Control 115 VAC

-202820 501 Electrode Control 230 VAC

-202830 501 Electrode Control 12 VDC

General

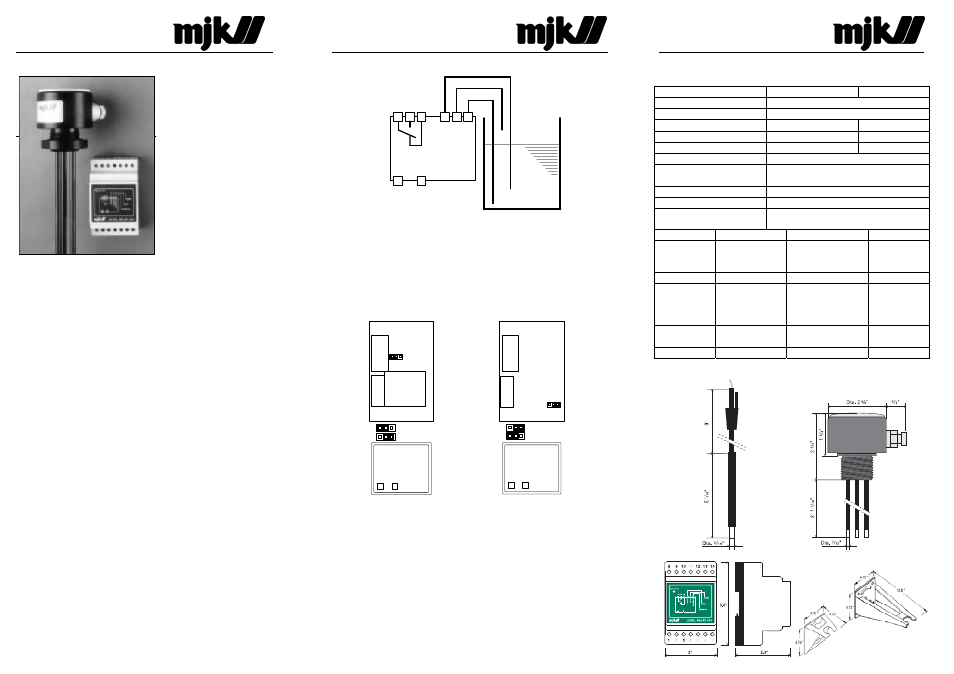

The 501 Electrode Control is a simple and price competitive system

for level control in conductive liquids. The system includes a

transmitter for DIN-rail mounting and various level electrodes.

Special Features

• Price competitive and reliable system for level control in

conductive liquids

• The amplifier is easily mounted on a DIN-rail

• The electrodes can be suspended by a cable or threaded directly

to a Lexan and Noryl plastic electrode base housing with a 1”

thread (see diagram at far right)

• The electrode base housing can be mounted on a special acid-

proof MJK 316 SS sensor brackets (200219 and 200220) which

can be wall mounted, pipe or rail mounted (using Universal

Brackets 200205) or mounted on a wall with an extension arm

(200210 plus 200215)

Function

The transmitter generates an alternating voltage applied to the

electrodes. When the liquid connects the electrodes, the current

running between these is amplified and the output relay is activated.

Two electrodes can be connected to the unit for the detection of

one level, or three electrodes can be connected for the detection of

two levels; one for start and one for stop. In cases where the liquid

is in a conductive tank, or where for example a metal pipe is in

constant contact with the liquid, the tank or piping can be

substituted for one of the electrodes by simply attaching a wire to it

and the connection housing, usually as a common contact. (see

diagram top middle).

Terminal Connections

8

9

12 13 14

1

3

10

C NO NC

SUPPLY

ST

O

P

ST

AR

T

CO

MM

O

N

COMMON

Terminal 13 must always be connected to the high-level electrode.

This also applies if you change from pumping out (default) to

pumping in. Only here it will function as the STOP electrode.

Settings for pumping out / pumping in

The 501 Electrode Control is set up from the factory to pumping

out (emptying). This setting can be changed to pumping in (filling)

by moving a jumper inside the cabinet as shown below:

115 VAC / 230 VAC

12 VDC

Fil

lin

g

Em

tyi

n

g

Re

lay

Fu

s

e

F

ill

in

g

Em

ty

in

g

Re

la

y

Fu

s

e

Emptying

Filling

Filling

Emptying

1

3

P

0

Supply

1

3

+

-

Supply

Part numbers

209820

501 Electrode Control / 115 VAC

202820

501 Electrode Control / 230 VAC

202830

501 Electrode Control / 12 VDC

202850

Level electrode (19 ft cable; normally not used

with electrode base)

202860

Electrode base with level electrode (1m rod)

202864

Electrode base with 4 level electrodes (1m rods)

202865

Level electrode for use with p/n 202860 (1m rod)

Specifications

Part numbers

209820 (202820)

202830

Dimensions

86 x 52,5 x 58 mm (h x w x d)

Mounting

On DIN-rail

Power supply

115 (230) VAC

±10%

11-16 VDC

Consumption (relay off)

-

<1mA

Comsumption (relay on)

Approx. 4VA

40mA

Temperature range

-4

°F to +140°F (-20°C to + 60°C)

Materials Cover

Base

Lexan (grey)

Noryl (black)

CE approvals

EN50081-1, EN50082-1

Enclosure

IP22

Relay output

Voltage-free switch

(max. 250V, 4A resistive,1A inductive)

Electrodes

202850 202860

(64)

202865

Description Single

electrode

Electrode base

incl. one (four)

electrode rod(s)

Additional

rod for p/n

202860

Enclosure IP68

IP65

IP68

Mounting Suspended

in

19.6 ft cable

incl. 5.9”

electrode

Mounted with M5

thread

Mounted in

base with

M5 thread

Length

5.9” / 150mm

39.4” / 1000mm

38.4” /

975mm

Materials

AISI 316

POM / AISI 316

AISI 316

Dimensions

501 Manual US 081104