Step 1 - float removal and replacement, Caution – Xylem MM 715B Series 63 64/764 and 65/165 Replacement Floats User Manual

Page 2

OFF

ON

2

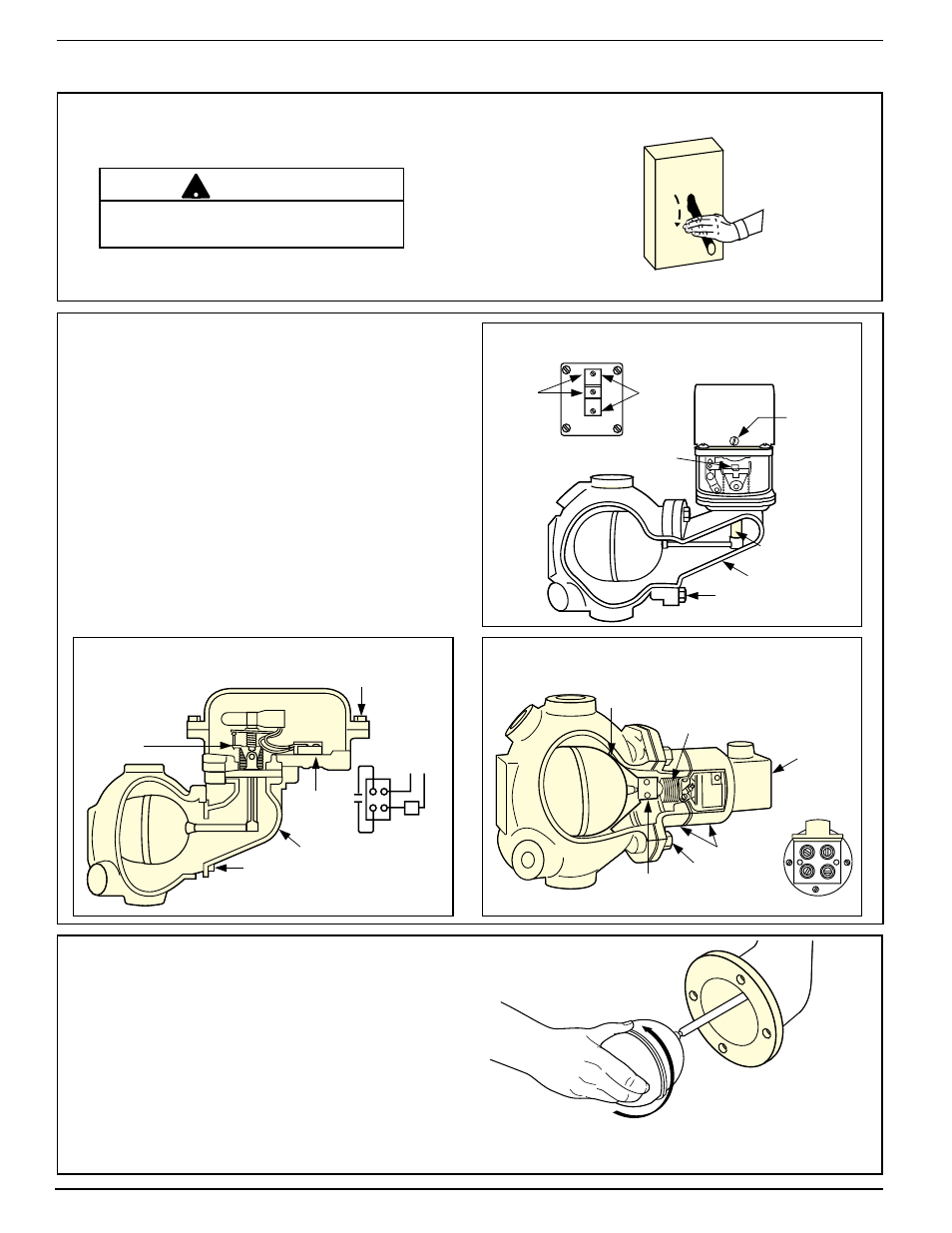

STEP 1 - Float Removal and Replacement

a. Turn power off to boiler and all controls.

Allow boiler to cool to 80˚F (27˚C) and

reduce the pressure to 0 psi (0 bar).

Drain water in the boiler to a level that is

below the float chamber.

b. Remove Head Assembly

• Remove screws (

A) and lift off

switch cover.

• Identify

terminal connections for

rewiring and then disconnect all wires

from

terminal panels.

• Remove head bolts. Carefully remove

head assembly from control body.

• Carefully place

head assembly in vice

where replacement work can be

performed more conveniently.

c. Remove and Replace Float

• While securely holding the

arm or mounting

block, where indicated in the diagram

above, unscrew

float ball from the assembly

Holding the arm or mounting block reduces

the risk of damaging the bellows from

unnatural stresses.

• Screw new float onto assembly.

On model 64 units, be sure the float stop

bracket is in proper position.

There may be more than one source of

power to the boiler.

!

CAUTION

SECURE THE FLOAT

ARM HERE

COVER

BOLTS (A)

LINE

TERMINAL

PANEL

HEAD ASSEMBLY

HEAD BOLTS

LOAD

C.

N.

N. C.

O.

LOW

WATER

ALARM

TERMINALS

LOW

WATER

CUT-OFF

TERMINALS

HEX HEAD BOLTS

HEAD ASSEMBLY

FLOAT ARM

SWITCH COVER

SCREW

(A)

TERMINAL PANEL

SECURE THE

FLOAT ARM HERE

FLOAT STOP

BRACKET

BELLOWS

SECURE

FLOAT MOUNTING BLOCK

HERE

HEX HEAD BOLTS

SWITCH COVER

TERMINAL PANEL

HEAD ASSEMBLY

1

TOP

2

3

4

MODEL 63-HD

MODEL 64-HD

MODEL 65-HD/165-HD