Xylem MM 711B Series 150, 150S, 157, 157S Bellows Replacement User Manual

Mcdonnell & miller, Warning, Instruction manual

INSTRUCTION MANUAL

MM-711B

Series 150, 150S, 157, 157S

Bellows Replacement

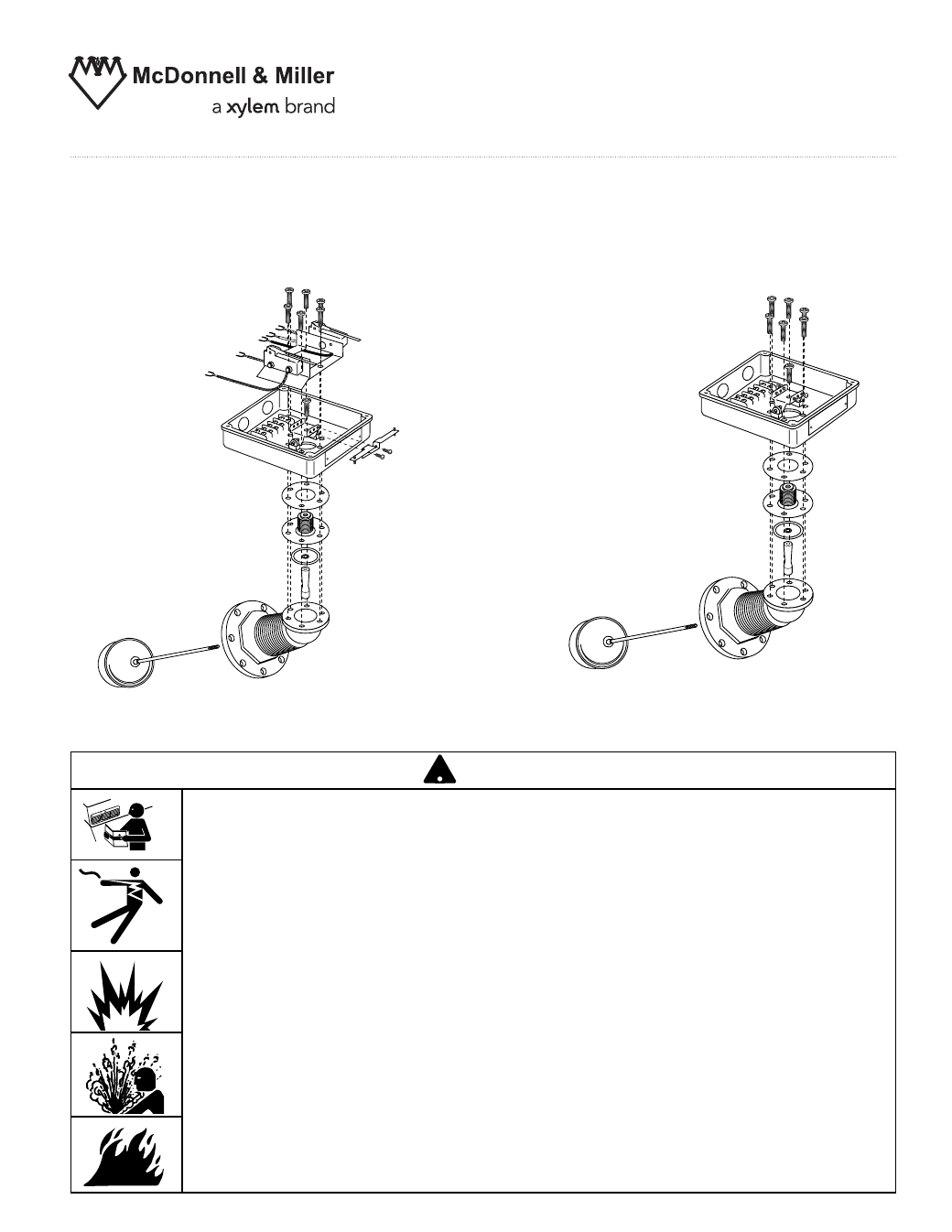

Series 150

Series 150S

• Before using product, read and understand instructions.

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application,

installation, and maintenance of plumbing, steam, and electrical equipment and/or systems

in accordance with all applicable codes and ordinances.

• To prevent electrical shock, turn off the electrical power before making electrical

connections.

• To prevent serious burns release all pressure and let boiler cool down to 80˚F (27˚C).

• Drain water level down below the float bowl chamber before taking the head mechanism

out of the body.

Failure to follow this warning could cause property damage, personal injury or death.

WARNING

CAUT

ION

!

WARNING

e. Screw float and float rod (C) into float arm (K)

and hand tighten. Center the float rod in the float

rod guide (not shown) and tighten Torx

®

screw (D)

to 125 in. lbs. (14N•m). Make sure you hold the

float in place while tightening screw (D). Move the

float up and down, making sure there is no binding

and that the float rod is still centered. Install bracket

(P) using screws (N), tighten to 40 in. lbs.

(4.5 N•m).

a. Clean the gasket surface on head casting (B) and the body casting. Using a new gasket (furnished)

mount the head mechanism to the body casting. Tighten the eight (8) bolts to 18 ft. lbs. (24N•m).

Reattach conduit connectors and connect wires to the proper terminals. Turn on electrical power to

the boiler.

STEP 4 - Assembling the Head to the Body and Test for Proper Operation

b. Run the unit through several cycles of operation, noting the operating points. On the snap

switch controls it may be necessary to readjust the switches. If this is necessary follow the

enclosed instructions. (See attached for reference only, MM-235).

d. Make sure the tapped hole on float arm (K) is

facing the correct way, so the float and float

rod (C) can be screwed into it when bellows

assembly is assembled on the head casting.

Place gasket (M) on head casting (B). Center the

gasket and place the bellows assembly (F) and

the switch housing (A) on head casting (B). Insert

and tighten the six (6) Torx

®

screws (E) to 125 in.

lbs. (14N•m). Make sure that two (2) of the screws

capture the switch bracket (R).

D

H

G

J

K

E

D

R

A

B

P

J

C

H

N

L

F

K

M

c. Take the new bellows assembly (F) and disassemble

it noting the order of parts. Put sealing washer (J)

on top of float arm (K) and insert into inside of

bellows (F). Place gasket (L) over bellows (F).

Insert this assembly into switch housing (A) and

bracket (H). If the screw (D) was an Allen

®

screw,

the spacer washer (G) will have to be put in the top

hole of bracket (H). Take Torx

®

screw (D)

(furnished) and insert it into hole on top of bracket

(H) and spacer washer (G) (if needed) and screw

into float arm (K). Hand tighten only.

Step 3 - Changing the Bellows for Snap Switch Units cont’d)

b. NOTE: On units that have Allen

®

head screws they

will be replaced with Torx

®

screws (furnished).

ITT

8200 N. Austin Ave.

Morton Grove, IL 60053

tel: 847-966-3700

fax: 847-966-9052

www.mcdonnellmiller.com

©2007 ITT Corporation

Printed in U.S.A. 5-07 246765

McDonnell & Miller