Step 1 - removal and replacement float, Caution – Xylem MM 713B Series 93/193 and 94/194 Replacement Floats User Manual

Page 2

2

OFF

ON

STEP 1 - Removal and Replacement Float

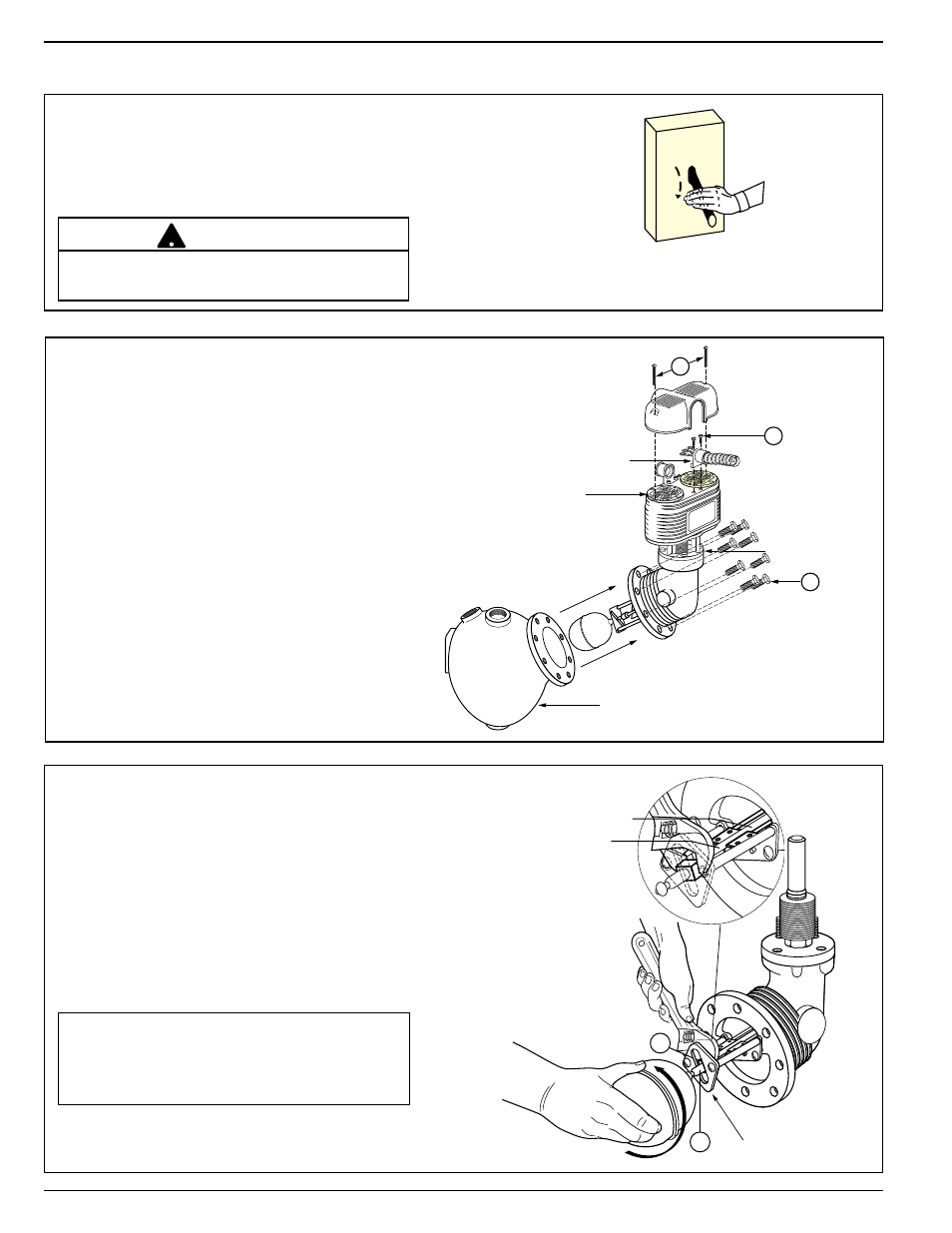

a. Turn power off to boiler and all controls.

Allow boiler to cool to 80˚F (27˚C) and

reduce the pressure to 0 psi (0 bar).

Drain water in the boiler to a level that is

below the float chamber.

CONDUIT FITTING

TERMINAL PANELS

HEAD ASSEMBLY

CONTROL BODY

B

A

C

b. Remove Head Assembly

• Remove two screws (

A) and lift off

switch cover.

• Identify

terminal connections for

rewiring and then disconnect all wires

from

terminal panels.

• Remove two screws (

B) and lift off

conduit fitting. Leave wires in conduit

for later reconnection.

• Remove head bolts (

C). There are eight

(8) on Series 93/193 and ten (10) on

Series 94/194. Carefully remove

head

assembly from control body.

• Carefully place

head assembly in vice

where replacement work can be

performed more conveniently.

D

FLOAT ARM SPRINGS

FLOAT ARM ROD

E

FLOAT STOP PLATE

c. Remove and Replace Float

• Place open end of adjustable wrench on

square section of float arm (

D) to keep it

from turning.

• Unscrew

float ball from arm.

• Screw new

float ball onto float arm rod

(

E), holding square section of float arm

nut (

D) with wrench and tighten securely.

IMPORTANT: Inspect condition of float

arm rod and float arm springs. If these

are damaged or bent, the entire head

assembly will need to be replaced.

There may be more than one source of power to

the boiler.

!

CAUTION