Flow rates, Installation, Step 1 - determine the location of the flow switch – Xylem MM 616F Series FS-5 General Purpose Liquid Flow Switch User Manual

Page 3

FLOW RATES

Settings will vary when used to sense flow of other

fluids.

3

NOTE:

DO NOT USE LIQUID FLOW

SWITCHES ON SYSTEMS WITH

FLOW VELOCITY GREATER THAN

10 FEET (3M) PER SECOND.

INSTALLATION –

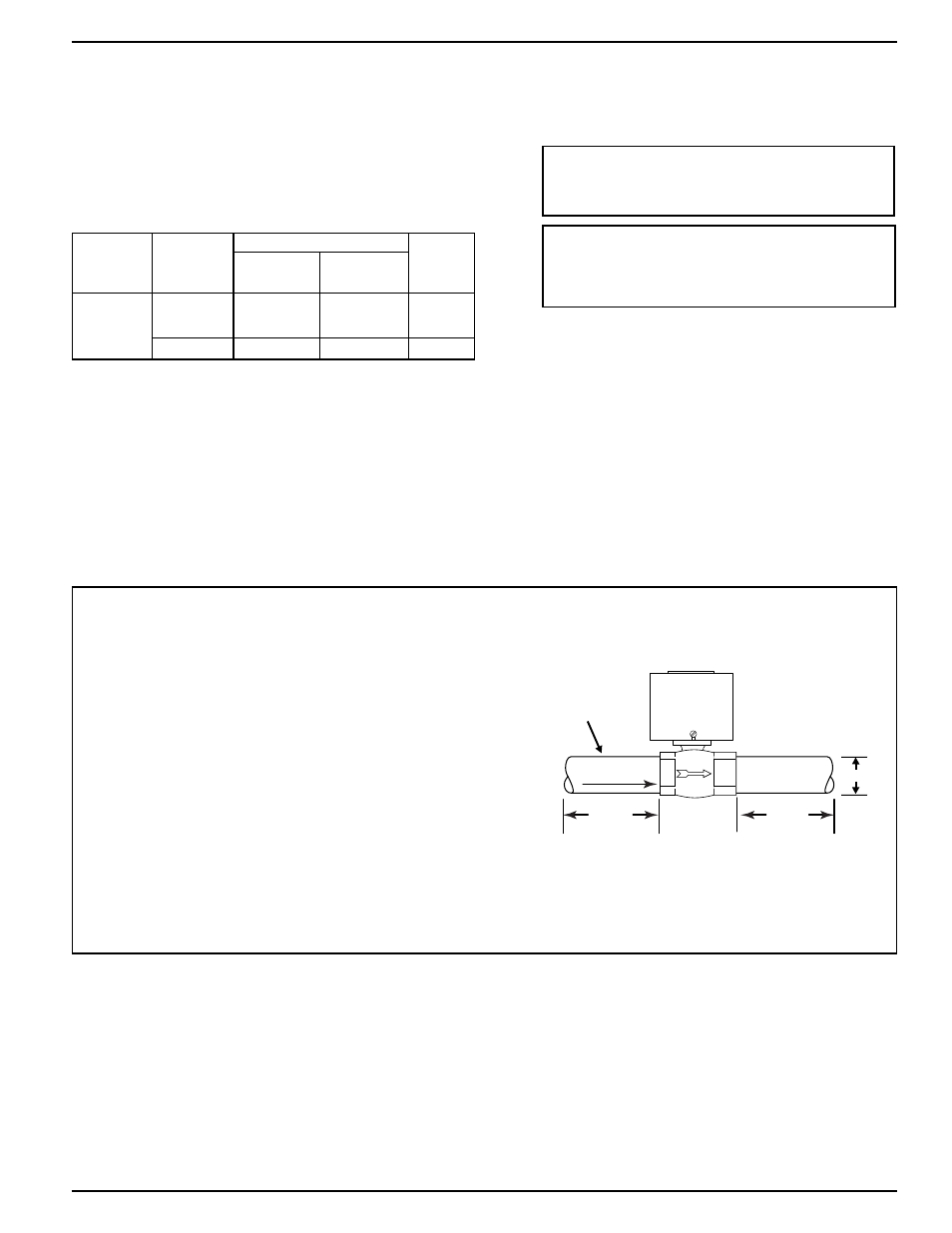

STEP 1 - Determine the Location of the Flow Switch

Fluid Flow

3/4

" or 1"

PIPE

5 x D

MINIMUM

D

D= PIPE DIAMETER

5 x D

MINIMUM

• The flow switch

should be located in a horizontal

section of pipe where there is a straight horizontal run

of at least 5 pipe diameters on each side of the flow

switch.

• The flow switch

must be installed in the upright

position as shown with arrow mark on side of casting

in the same direction as fluid will flow.

• Some system conditions that require more than 5 pipe

diameters are high viscosity fluid and high fluid velocity.

• The flow switch should be installed in the pump suction

piping when spring-loaded check valves and/or other

close coupled accessories are installed in the pump

discharge piping.

Flow Rates

Pipe

Mode of Operation

Size NPT

Flow

No Flow

in. (mm)

Settings

gpm (lpm)

gpm (lpm)

3

⁄

4

(20)

Factory or

or

Minimum

1.5

(5.7)

1.1

(4.2)

16.62 (63)

1

(25)

Maximum

15 (56.8)

10

(37.9)

27 (102)

Values are ± 10%

Max. Flow

Rate gpm

(lpm) w/o

Paddle Damage

NOTE: THIS PRODUCT IS NOT INTENDED

FOR USE IN POTABLE WATER

APPLICATIONS.

calculated using clean water in a horizontal pipe.

Flow rates required to activate the flow switch

are shown in chart below.These values were