Flow rates, Installation, Step 1 - determine the location of the flow switch – Xylem MM 615D Series FS1 High Sensitivity Liquid Flow Switch User Manual

Page 3: Psi flow switch capacity - fsi

P

10

20

30

40

50

60

70

80

90

8.35

11.50

13.60

15.75

17.75

19.75

21.25

23

24.25

Mode of Operation

Flow

No Flow

Settings

gpm (lpm)

gpm (lpm)

Factory or

Minimum

0.41 (1.55)

0.24

(.91)

25

Maximum

1.81 (6.85)

1.28

(4.84)

(95)

FLOW RATES

Settings will vary when used to sense flow of other

fluids.

3

NOTE: DO NOT USE LIQUID FLOW

SWITCHES

ON

SYSTEMS

WITH

FLOW VELOCITY GREATER THAN

10 FEET (3M) PER SECOND.

INSTALLATION –

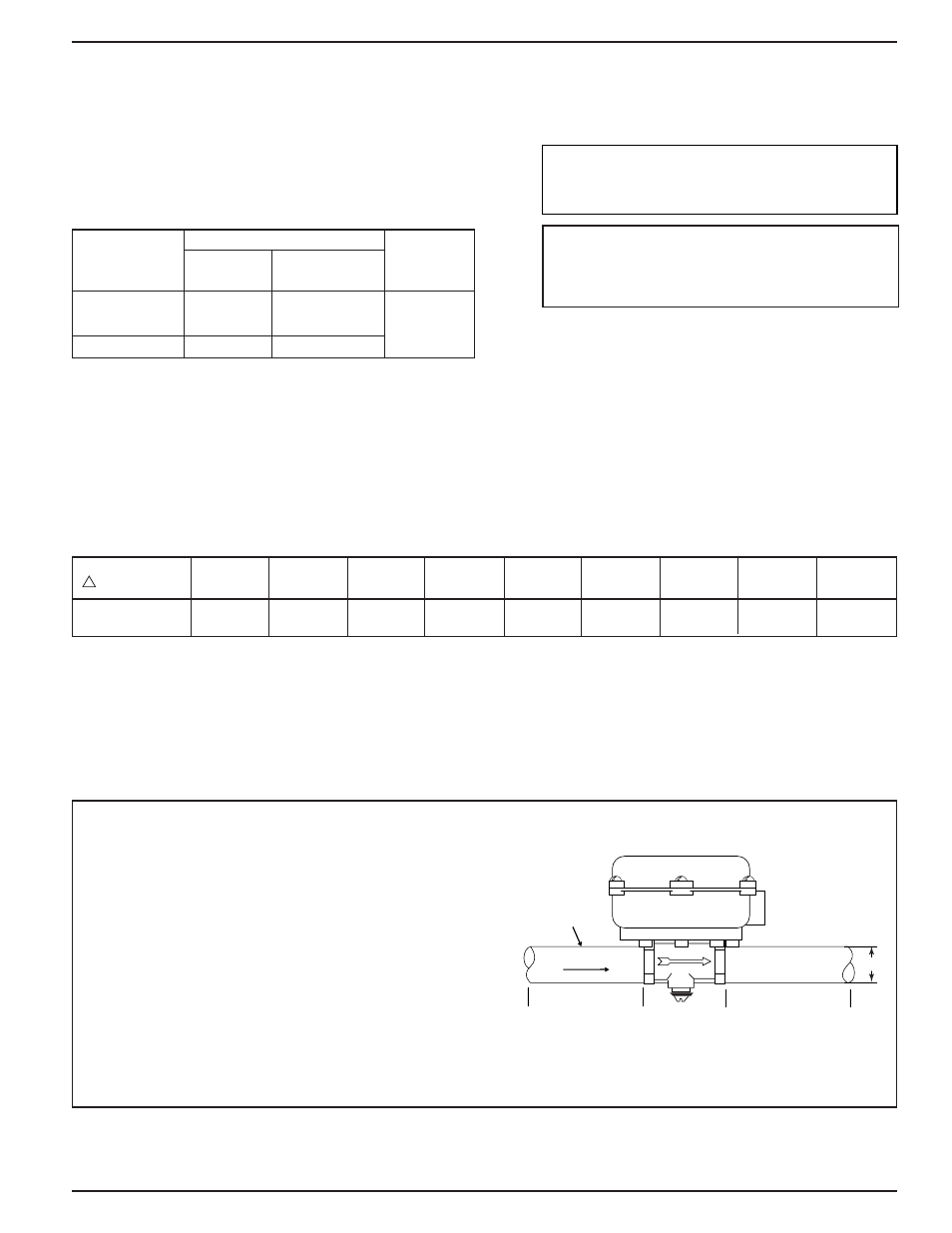

STEP 1 - Determine the Location of the Flow Switch

D

5 x D

MINIMUM

1/2

" PIPE

5 x D

MINIMUM

FLUID FLOW

D= PIPE DIAMETER

• The flow switch should be located in a horizontal

section of pipe where there is a straight horizontal

run of at least 5 pipe diameters on each side of the

flow switch.

• The flow switch must be installed in the upright

position as shown with arrow mark on side of casting

in the same direction as fluid will flow.

• Some system conditions that require more than 5

pipe diameters are high viscosity fluid and high fluid

velocity.

NOTE: “L” models are set at the factory to prove flow at 1.7 gpm. The setpoint should not be adjusted in the

field without consulting factory.

Flow Rates

Values are ± 10%

Max. Flow Rate

gpm (lpm) w/o

Paddle Damage

PSI Flow Switch Capacity - FSI

DIFFERENTIAL

PRESSURE

GPM

CAPACITY

calculated using clean water in a horizontal pipe.

Flow rates required to activate the flow switch

are shown in chart below.These values were

NOTE: THIS PRODUCT IS NOT INTENDED

FOR USE IN POTABLE WATER

APPLICATIONS.