Installation, For 193-d models – Xylem MM 404J Series 93/193 and Series 94/194 Low Water Cut-Off/Pump Controllers For Steam Boilers and Level Control Applications User Manual

Page 4

4

A

B

C

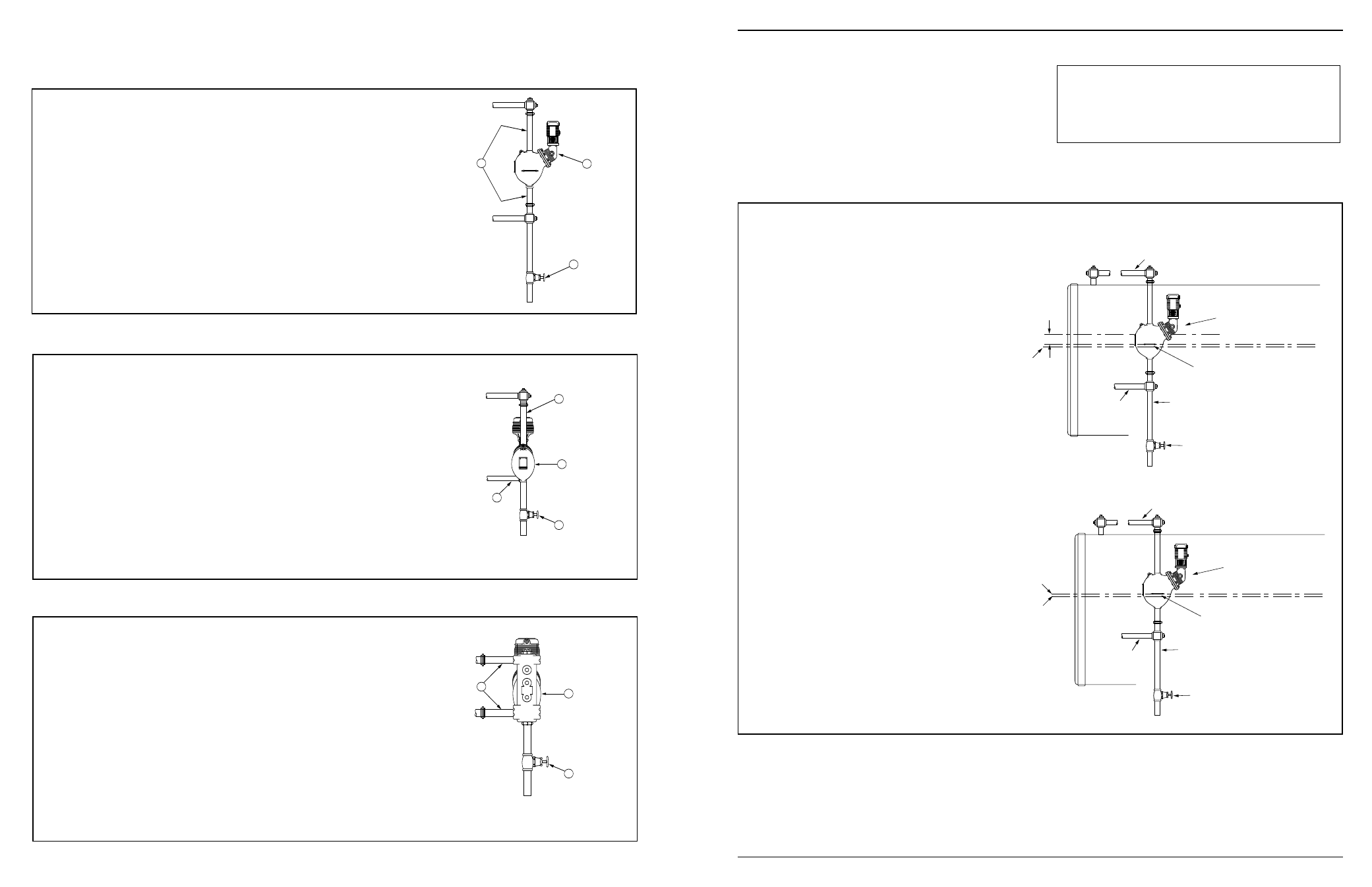

a. Mount and pipe the control (A) on vertical equalizing

pipes (

B) at the required elevation as determined in

Step 1.

Install a full-ported blow-down valve (

C) directly

below the lower cross.

NOTE:

1” (25mm) NPT tappings are provided on Series

93/193 controls.

1 1/4” (32mm) NPT tappings are provided for Series

94/194 controls and 193-B Model.

STEP 2 - Installing the Low Water Cut-Off/Pump Controller

For Series 93/193 or 94/194 (except 94-A, 193-D and 193-G Models)

A

E

C

D

a. Mount and pipe the control (A) with a vertical upper

(

D) and horizontal lower (E) equalizing piping at the

required elevation as determined in Step 1.

Install a full-ported blow-down valve (

C) on the lower

body connection.

NOTE:

1 1/4” (32mm) NPT tappings are provided for 94-A

Model control.

1” (25mm) NPT tappings are provided for 193-G

Model control.

For 94-A and 193-G Models

A

C

G

a. Mount and pipe the control (A) with a horizontal

upper and lower (

G) equalizing piping at the

required elevation as determined in Step 1.

Install a full-ported blow-down valve (

C) on the lower

body connection.

NOTE:

1” (25mm) NPT tappings are provided for 193-D

Model control.

For 193-D Models

3

If the control will be the primary low

water fuel cut-off, size the steam (top) and

water (bottom) equalizing pipe lengths so

that the horizontal cast line on the body is

1 1/2” (38mm) below the boiler’s normal

water level,

but not lower than the lowest

safe permissible water level, as deter-

mined by the boiler manufacturer.

OR

If the control will be the secondary low

water fuel cut-off, size the steam (top) and

water (bottom) equalizing pipe lengths so

that the horizontal cast line on the body is

at or above the lowest safe permissible

water level, as determined by the boiler

manufacturer.

STEP 1 - Determine the Position of the Low Water Cut-Off/Pump Controller

INSTALLATION –

TOOLS NEEDED:

Two (2) pipe wrenches, one (1) flathead screw

driver, and pipe thread dope.

IMPORTANT: Follow the boiler manufacturer's

instructions along with all applicable codes and

ordinances for piping, blow-down valve, water

gauge glass, tri-cock and electrical requirements.

1

1

/

2

"

STEAM EQUALIZING PIPE

VERTICAL EQUALIZING PIPE

BLOW DOWN VALVE

NORMAL BOILER WATER LINE

AS A PRIMARY

LOW WATER CUT-OFF/PUMP

CONTROLLER

BURNER “CUT-OFF LEVEL”

AT CAST LINE

LOWEST

PERMISSIBLE

WATER LEVEL

WATER

EQUALIZING

PIPE

STEAM EQUALIZING PIPE

VERTICAL EQUALIZING PIPE

BLOW DOWN VALVE

AS A SECONDARY

LOW WATER CUT-OFF/PUMP

CONTROLLER

BURNER “CUT-OFF LEVEL”

AT CAST LINE

LOWEST

PERMISSIBLE

WATER LEVEL

BURNER OFF

WATER

EQUALIZING

PIPE