Step 3 - testing and inspection, Caution – Xylem MM 315E Models 51, 51S and 53 Boiler Water Feeders Models 51-2, 51-S-2 and 53-2 Feeder Cut-Off Combinations User Manual

Page 6

6

STEP 3 - Testing and Inspection

Blow-Down

Valve

Feeder

Valve

Closing

Level

The feeder should be blown down after initial installa-

tion, before leaving site. It should also be blown down

as recommended in the Maintenance section of these

instructions.

• Burner should be on and water level above 'closing

level' of feeder.

• Slowly open the water feeder blow down valve, which

will lower the water level in the float chamber. As

water flows out the blow down pipe, you should begin

to hear the feeder valve open.

• If the feeder has a #2 switch, the burner should stop.

• Close the water feeder blow down valve. The water

level should return to a safe operating level and the

burner should turn on.

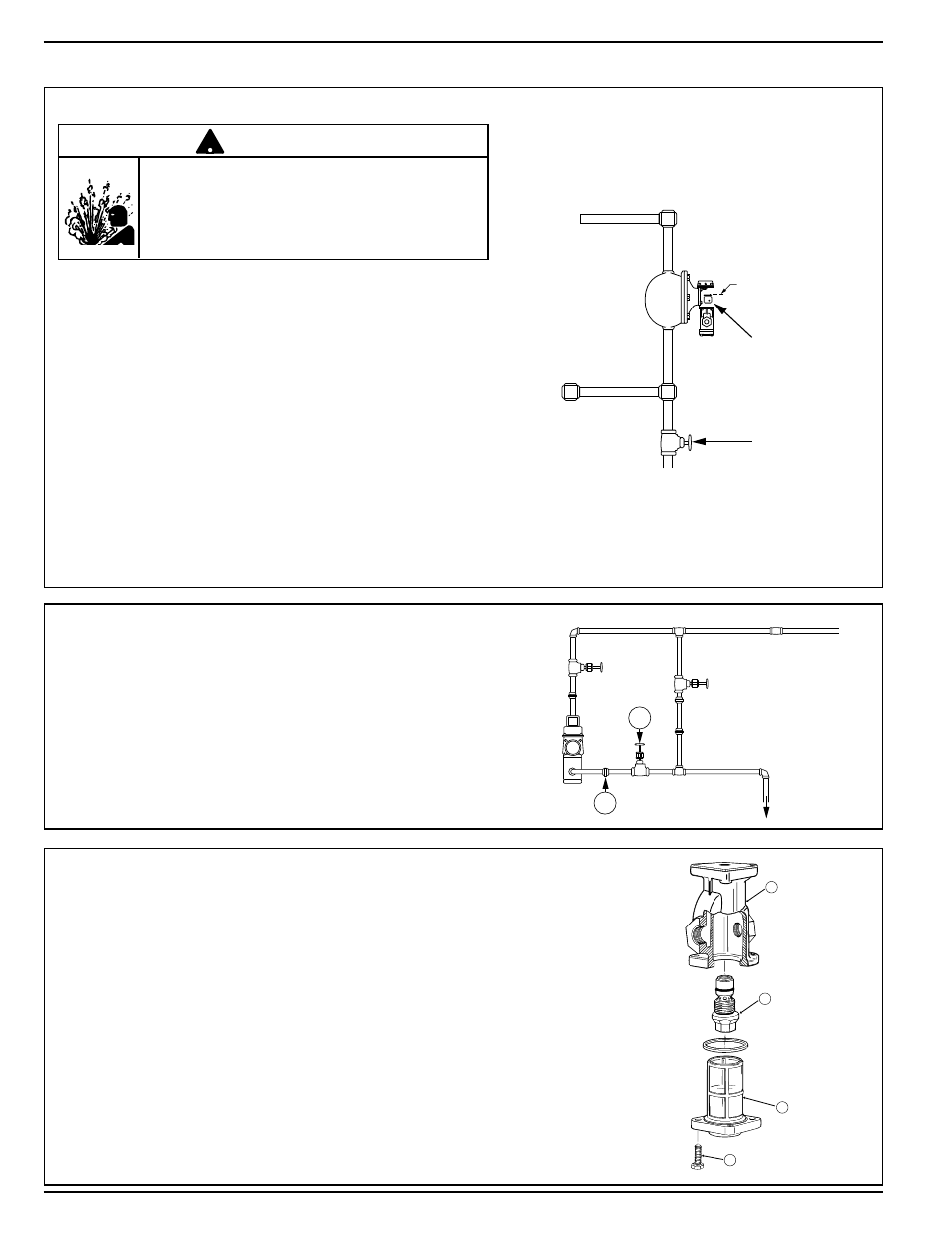

To prevent serious personal injury from steam pipe

blow down, connect a drain pipe to the control

opening to avoid exposure to steam discharge.

Failure to follow this caution could cause personal

injury.

!

CAUTION

Swing check

TO BOILER

By-pass

valve

A

B

Make sure that the water level in the boiler is above the

closing level of the feeder.

Close valve 'A' and slowly open union 'B' to determine if

valve is leaking.

• If water is leaking from the union, the valve needs to

be serviced.

• If no water leaks from the union, the feeder operation

is not the cause of the flooding.

Broken Union Test

Blow Down of Feeder

E

D

B

H

x 4

A. Using a 1/2" socket wrench, unscrew the four (4) hex-head

bolts (B) that secure the strainer basket (H) to the valve

assembly (E).

B. Using a 13/16" socket wrench, unscrew the cartridge (D)

and remove.

C. Clean any debris (scale, rust, etc.) from strainer and cartridge.

Poppet inside cartridge must move freely. Replace if debris

cannot be removed or poppet does not move freely.

D. Lubricate cartridge o-rings using silicone type lubricant and

re-install.

E. Re-install strainer basket.

Series 51

Removal of cartridge and strainer for inspection and cleaning