Operation capacities, Typical installations – Xylem MM 317C Models 21 & 221 Mechanical Water Feeders User Manual

Page 2

2

OPERATION

Capacities

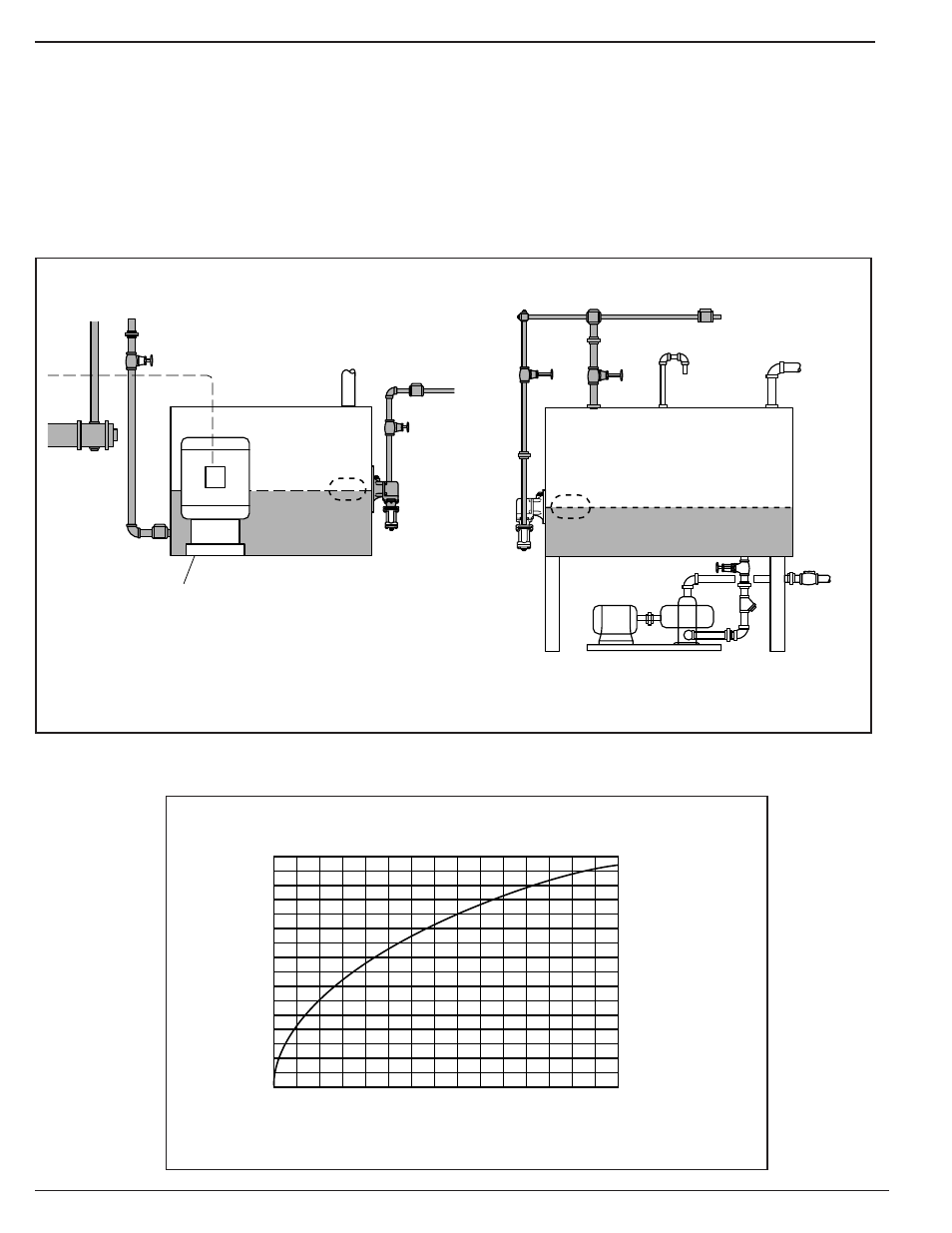

WATER SUPPLY PRESSURE IN LBS. PER SQ. IN.

CAPACITY CURVE

lbs./hr.

psi

(kg/hr.)

130

120

110

100

90

80

70

60

50

40

30

10

16,000

15,000

14,000

13,000

12,000

11,000

10,000

9,000

8,000

7,000

6,000

5,000

4,000

3,000

2,000

1,000

0

(7258)

(6804)

(6350)

(5897)

(5443)

(4990)

(4536)

(4082)

(3629)

(3175)

(2722)

(2268)

(1814)

(1361)

(907)

(454)

(0)

(0.7)(1.4)(2.1)(2.8)(3.5)(4.2)(4.9)(5.6)(6.3)(7.0)(7.7)(8.4)(9.1)(9.8)(10.5)

20

0

(0)

140 150

32

30

28

26

24

22

20

18

16

14

12

10

8

6

4

2

0

(121.12)

(113.55)

(105.98)

(98.41)

(90.84)

(83.27)

(75.70)

(68.13)

(60.56)

(52.99)

(45.42)

(37.85)

(30.28)

(22.71)

(15.14)

(7.57)

(0)

(kg/cm

2

)

gpm

(lpm)

464

435

406

377

348

319

290

261

232

203

174

145

116

87

58

29

0

(4549)

(4264)

(3980)

(3696)

(3411)

(3127)

(2843)

(2559)

(2274)

(1990)

(1706)

(1421)

(1137)

(853)

(569)

(284)

(0)

Boiler Hp

(kilowatts)

The Series 21 make-up water feeder provides

dependable, float-operated automatic water filling

service to tanks used as condensate receivers in

boiler systems. The valve components are of brass,

an elastomer sealing disc and stainless steel materi-

als, and a 4-3/4” diameter copper float providing

closure against supply pressure up to 150 PSI. An

integral strainer and housing with removable drainage

plug precede the valve for regular servicing. The con-

trol is a direct-feeding unit (feeds through the flange

connection) available in two flange sizes.

TYPICAL INSTALLATIONS

MODEL 221

Boiler

Feed

Tank

Feed Pump

City Water Supply

Check Valve

Bypass

Condensate Receiver Tank

Pump

Discharge

Feed Pump

MODEL 21