Bell & Gossett V59074B Low Flow Circuit Sentry Model ACL Flow Limiting Valves User Manual

Page 3

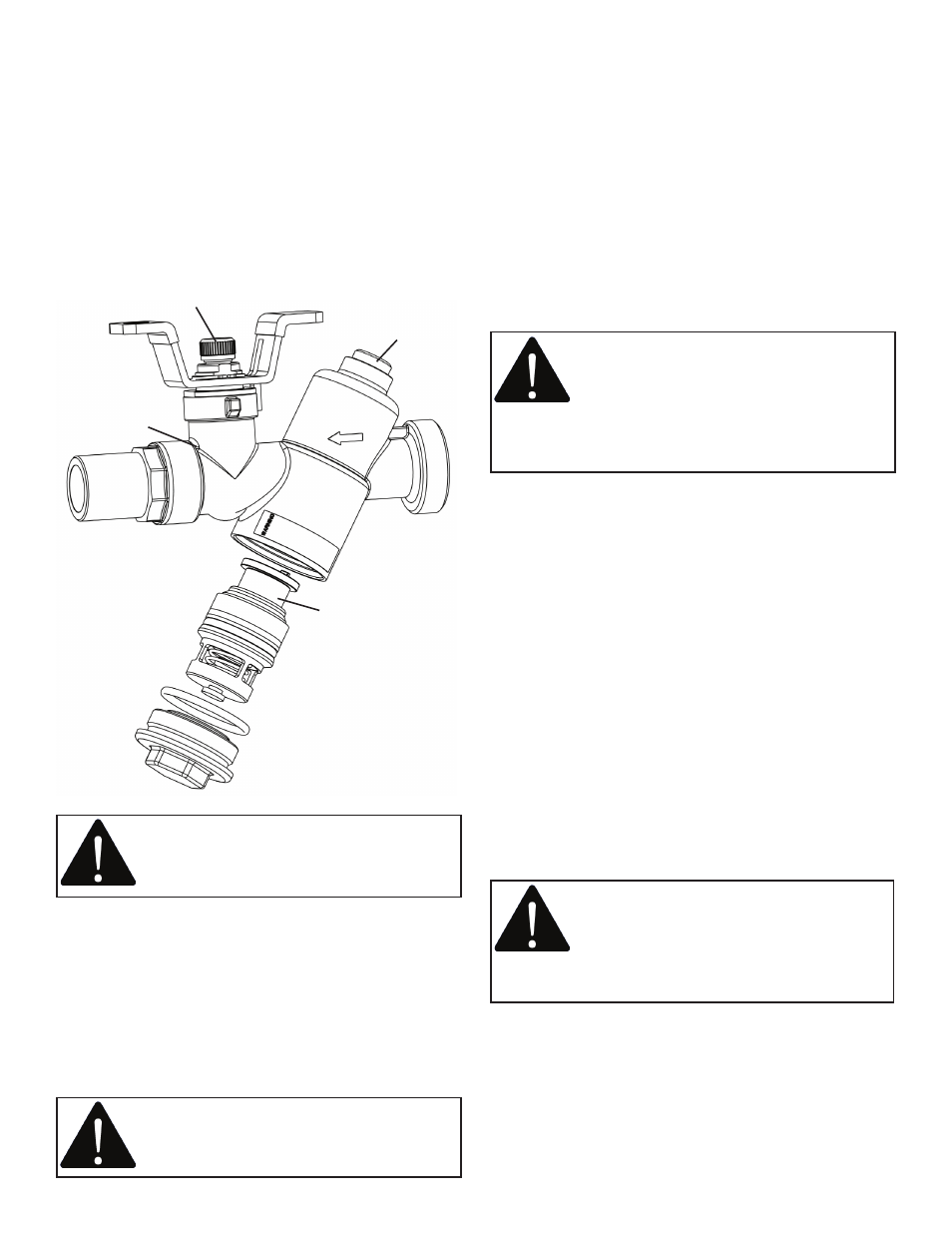

Prior to coil commissioning and operating the Flow

Limiting Valve, adjust cartridge to the desired flow rate

between 0.25 GPM to 3.8 GPM.

1.

Loosen screw (a) position.

2.

Rotate plastic dial (b) to the desired flow rate.

Increments marked on variable orifice are in GPM.

3.

Re-tighten screw (a) with dial set at the desired

flow rate.

4.

Install the cartridge as shown below.

OPERATION INSTRUCTIONS

HOW TO USE BELL & GOSSETT LOW FLOW CIRCUIT

SENTRY MODEL ACL FLOW LIMITING VALVES FOR

PRE-SET FLOW BALANCING

Operation of the Flow Limiting Valve is fully automatic.

It automatically maintains the selected flow over the

designed differential pressure range.

CAUTION: Make sure Valve Cap is properly

assembled. Failure to follow these

instructions can result in personal injury and/

or property damage.

Before system start up, remove the flow limiting cartridge

from the valve, if previously installed. Flush the hydronic

system as part of commissioning and then reassemble

cartridge into the valve. Make sure the valve cap is

tightened properly. Start the system and inspect the Low

Flow Circuit Sentry ACL valve for leakage.

HOW TO USE PRESSURE TAPS (P/T PORTS) TO MEASURE

SYSTEM OPERATING CONDITIONS

Using Bell & Gossett Model RP-250B, readout probes,

attach Bell & Gossett differential pressure readout kit to

the readout valves (P/T ports) on the Low Flow Circuit

Sentry ACL valve.

Read the differential pressure from the coil inlet

isolation valve (typically strainer) to coil isolation valve

(typically a flow limiting balancing valve). The

differential value minus the pressure drops across the coil

and installed control valves should be less than 60 psi for

proper flow control.

If more accurate readings are desired, a pressure readout

valve (B&G P/N V58050) may be installed (B) in the barrel

above the cartridge chamber of the flow limiting valve.

Pressure readings should then be taken from the P/T valve

located in the isolation valve (A) and the P/T valve located

in the barrel of the cartridge (B). The differential valve

should be less than 60 psi for proper control.

CAUTION: Hot un-insulated surfaces can

cause burns to the skin. Do not touch hot

surfaces. Failure to follow these instructions

could result in personal injury.

WARNING: Hot water leakage can occur

from readout valves (P/T ports) during probe

insertion and during hookup of readout kit.

Follow the instruction manuals supplied

with readout probes and readout kits for safe use.

Failure to follow these instructions could result in

serious personal injury or death and property damage.

SERVICE INSTRUCTIONS

Periodically inspect the Low Flow Circuit Sentry Model

ACL Flow Limiting Valve for signs of leakage or corrosion.

Replace valve cap o-ring (V57754), if necessary

WARNING: Corrosion or leakage are

indications that the Low Flow Circuit Sentry

Model ACL Flow Limiting Valve must be

replaced. Failure to follow these

instructions could result in serious personal injury or

death and property damage.

Due to the different types of material used, the Low Flow

Circuit Sentry Model ACL Flow Limiting Valve must be

disassembled prior to disposal. Special handling of

certain valve components may be required by law or may

be sensible from an ecological point of view.

Isolation Valve

Installed P/T Port (A)

Flow Cartridge

Optional P/T

Port (B)