Installation instructions – Xylem Parshall flumes User Manual

Page 2

2

Installation instructions

MJK Automation A/S

Byageren 7

DK-2850 Nærum

Denmark

Tel.: (+45) 45 56 06 56

Fax: (+45) 45 56 06 46

[email protected]

www.mjk.dk

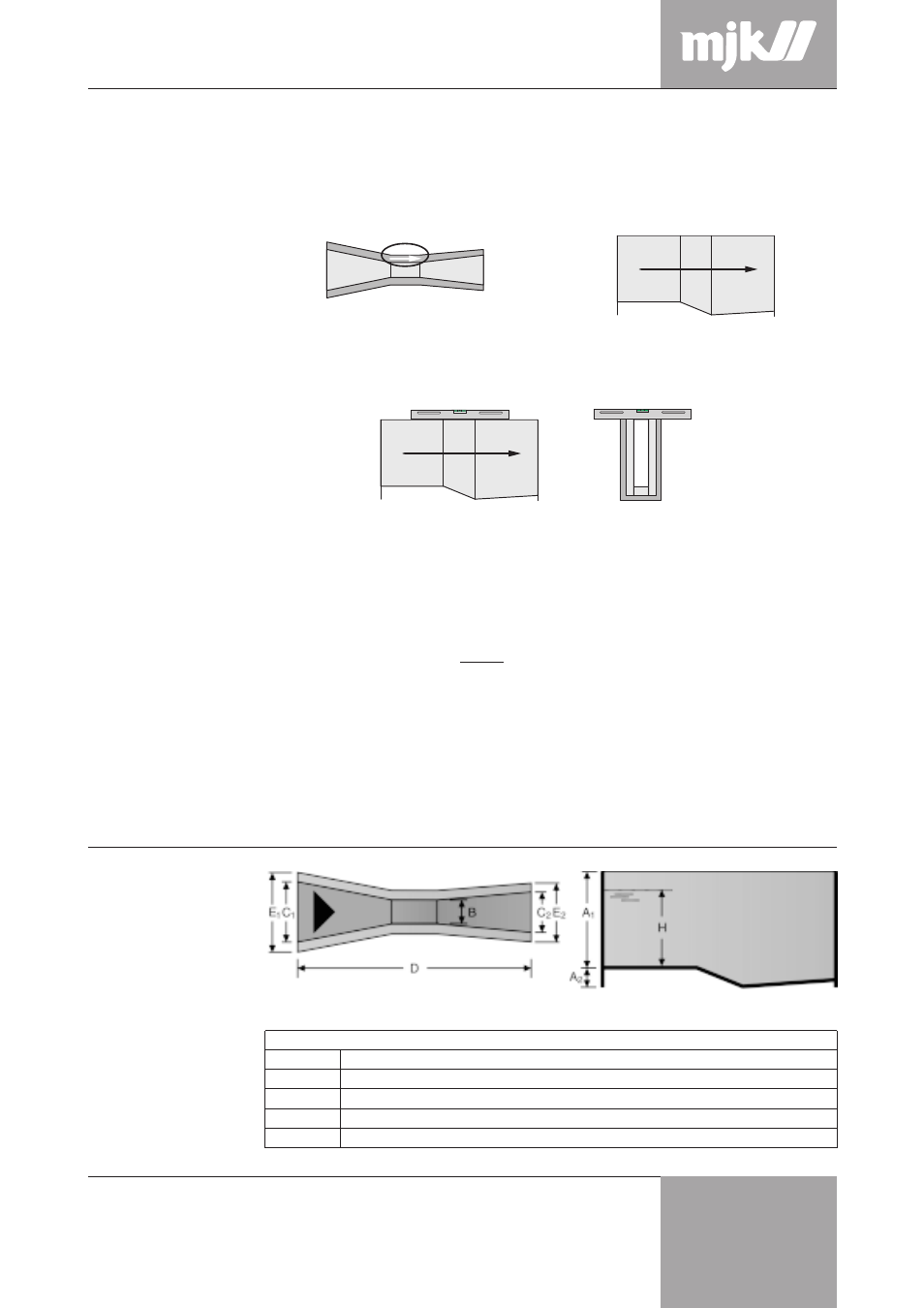

Mounting of the flume

Dimensions

Size

A1

A2

B

C1

C2

D

E1

E2

2 inch

410

58

50.8

214

135

774

334

255

3 inch

610

75

76.2

259

178

914

379

298

6 inch

610

155

152.4

397

394

1525

517

514

9 inch

762

143

228.6

575

381

1626

695

501

12 inch

914

270

304.8

845

610

2867

965

730

All measurements in mm

The flume is designed to be moulded into concrete. Concrete with a low content of water

should be used - a plasticizer can be mixed in.

1 Position the flume correctly in relation to the flow direction. Observe the flow direction as

indicated with an arrow on the top edge of the flume:

2 Fix the flume in the shuttering and make sure it is precisely leveled in both directions.

3 Cover inlet and outlet with plywood board or similar and put a piece of wood inside the

flume to support its sides.

4 Fill concrete into the shuttering until it lies a little higher than the bottom of the flume and

vibrate, so that the concrete becomes well distributed under the flume.

NB! Let the concrete harden before filling the sides of the shuttering, so the flume will be

firmly secured in the concrete.

5 Fill both sides with concrete. Do not vibrate the concrete at the sides of the flume!

6 A 10 mm elastic infill along both sides of the flume is recommended to prevent water

penetration and possible frost fracture.

7 Mount the sensor bracket so that the sensor will be located at a distance ‘L’ from the

flume throat as explained on the front page.

Flow direction!

Levelled both laterally and longitudinally!

Sensor distance