Ao55 – Seametrics AO55 User Manual

Page 3

0

9

8

7 6 5 4

3

2

1

0

9

8

7 6 5 4

3

2

1

0

9

8

7 6 5 4

3

2

1

0

9

8

7 6 5 4

3

2

1

Power

Sensor

4-20 mA

AO55

Frequency

SETTINGS, CALIBRATION and FREQUENCY

SETTINGS

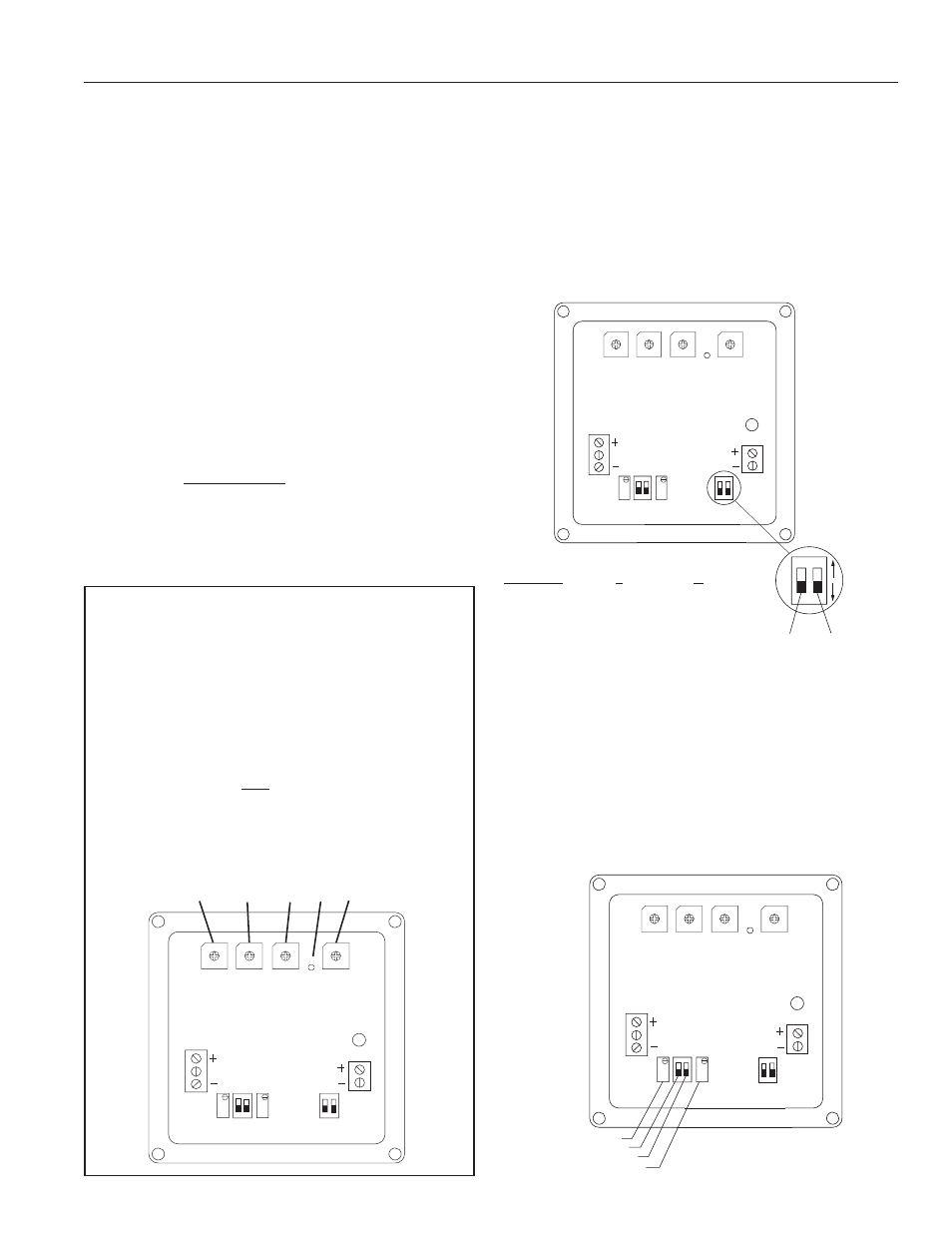

Setting Frequency.

The AO55 converts a train of off/on pulses

from the flow sensor into a continuous milliAmp signal that

ranges from 4 mA at zero flow to 20 mA at the desired maximum

flow. The desired maximum is determined by the user and

entered as a frequency as follows:

1)

2)

3)

4)

Setting Averaging Time.

For most applications, this step can

be ignored, as the standard setting will work fine. However,

when a particularly steady output signal is desired, or in

large pipe, a larger averaging period may be desirable. Note

however that the averaging period requires a tradeoff, since

a longer averaging period implies a slower response time. If

steady signal is more important than fast response, increase

the averaging time as desired. See the diagram below for the

switch positions and their corresponding times.

Decide what flow rate should represent the top of the

scale. This is ordinarily the maximum expected flow, or

a value just above it, in gallons per minute.

Locate the K-factor of the flow sensor (found on the

meter or fitting, or in the instruction manual, depending

on meter model). The K-factor is the number of pulses

the flow sensor produces per gallon of flow.

Calculate frequency, using this formula:

K-Factor x Top Flow (GPM) = Frequency

60

Enter the frequency using the four rotary Frequency

switches. Note the decimal point between the third

and fourth switches.

Checking Calibration

Normally it should not be necessary to check calibration, since

the digital design of this unit virtually eliminates drift. However,

there are two types of calibration check that can be performed.

Look at the diagram below to locate the 4 and 20 mA force

switches. To force the 4 mA output, put its switch in the up

position. Check the current output at the Power terminals, and

if necessary trim to 4.00 mA using the appropriate trimpot.

Return the switch to the down position, and repeat the process

with the 20 mA switch.

In an installation with an estimated maximum flow rate

of about 150 GPM, a flow rate of 170 GPM is selected

as the full-scale maximum, the flow at which the current

loop will register 20 mA.

In this example, the K-factor (found on the meter or

fitting, or in the manual) is “K = 54.50”.

Calculate the frequency as

1

5

4 . 4

Rounding to one decimal point, enter 154.4 on the

rotary switches by turning the rotary switch pointers

to the desired digits.

= 154.42

54.50 x 170

60

SETTING FREQUENCY EXAMPLE

1)

2)

3)

4)

0

9

8

7 6 5 4

3

2

1

0

9

8

7 6 5 4

3

2

1

0

9

8

7 6 5 4

3

2

1

0

9

8

7 6 5 4

3

2

1

AO55

Frequency

Power

Sensor

4-20 mA

UP

DOWN

L

R

0

9

8

7 6 5 4

3

2

1

0

9

8

7 6 5 4

3

2

1

0

9

8

7 6 5 4

3

2

1

0

9

8

7 6 5 4

3

2

1

AO55

Frequency

Power

Sensor

4-20 mA

4mA Adjust

Force 4 mA

Force 20 mA

20 mA Adjust

S

Switch Position

Seconds

L

R

2

down down

4

down

up

8

up

down

16

up

up