Operation, 435 psig standard design, 150 psig pressure design – Xylem BrazedPlate Heat Exchangers User Manual

Page 3: Caution

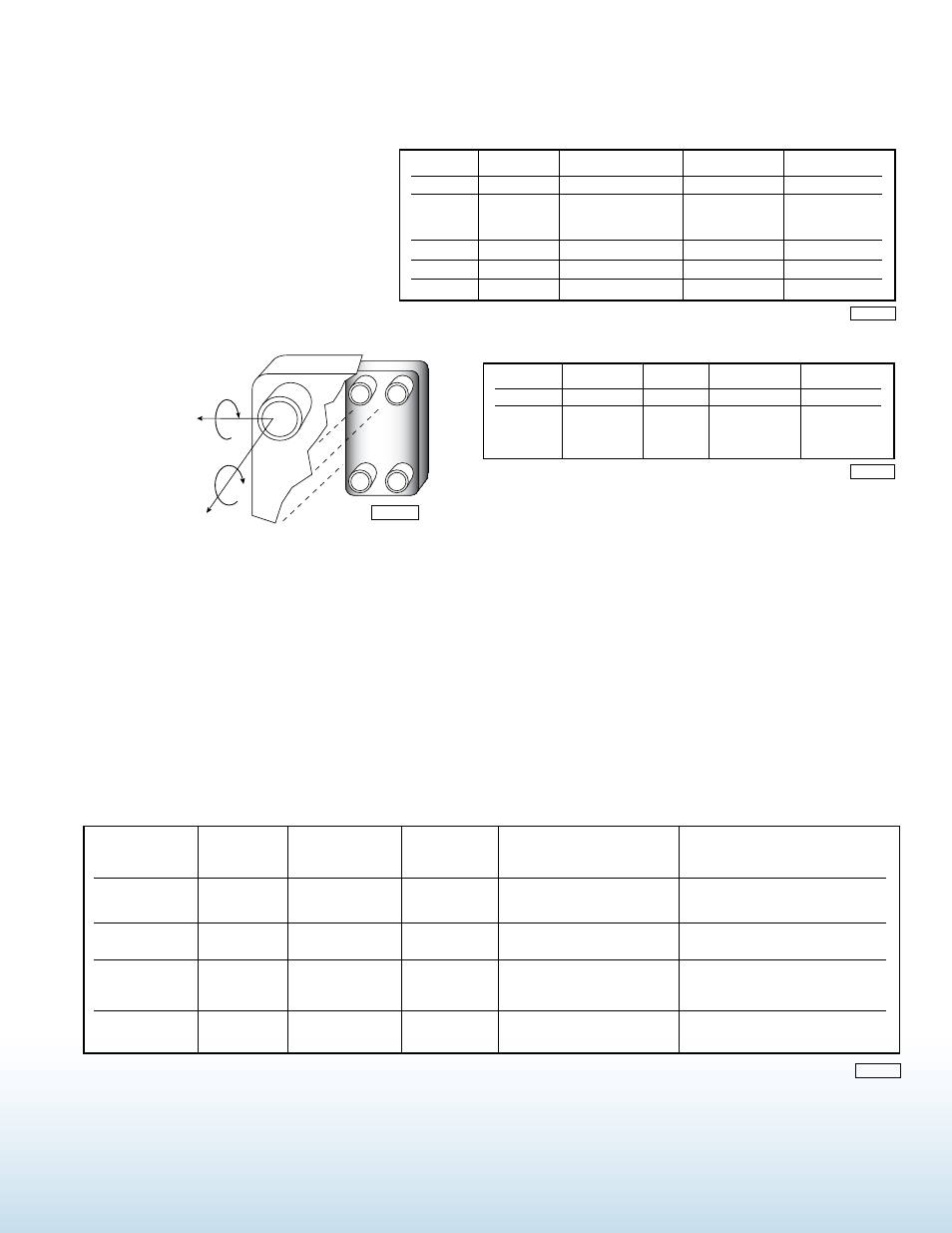

FIGURE 1

FIGURE 2

T

Mb

Mv

F

Operation

Liquid

Hot

Liquid

Cold

Gas

Hot

Liquid

Cold

Condensing Gas

Hot

Liquid

Cold

Liquid or Gas

Hot

Vaporizing Liquid Cold

Condensers

REFRIGERATION:

STEAM TO LIQUID

Refrig. In:

F1

Refrig. Out:

F4

Liquid In:

F3

Liquid Out:

F2

Evaporators

Refrig. In:

F4

Refrig. Out:

F1

Liquid In:

F2

Liquid Out:

F3

Evaporators

Refrig. In: ......... F4

Refrig. Out: ...... F1

Liquid In:............ F2

Liquid Out: ......... F3

Condensers

Steam In:

F1

Condensate Out: F4

Liquid In:

F3

Liquid Out:

F2

STEAM TO LIQUID

Condensers

Steam In: ......... F1

Condensate Out: F4

Liquid In:............ F3

Liquid Out: ......... F2

Model

T (lbs)

F (lbs)

Mb (in-lbs)

Mv (in-lbs)

400

3327

1798.4 (-1348.8)

327.5

1504.6

410

411

5552.6

1798.4 (-1348.8)

540

1504.6

412

415

5552.6

2158.1 (-1663.5)

540

3407.5

422

24952.8

6069.6 (-4720.8)

6550

8912.7

433

Consult

Factory

Consult

Factory

Model

T (lbs)

F (lbs)

Mb (in-lbs)

Mv (in-lbs)

400

200

100

20

200

410

411

280

130

27

300

412

Start both fluids gradually

at the same time.

Start cold fluid

first then hot fluid.

Start hot fluid first then

slowly start cold fluid.

Avoid temperature shock.

Start hot fluid

first then cold fluid.

Shut down both fluids

gradually at the same time.

Shut down hot fluid

gradually then cold fluid.

Shut down cold fluid

first then hot fluid.

Shut down cold fluid

first then hot fluid.

Type of Fluid

Relative

Type of Fluid

Relative

Start-Up

Shut-Down

Temperature

Temperature

Procedure

Procedure

Condensers

REFRIGERATION:

Refrig. In: ......... F1

Refrig. Out: ...... F4

Liquid In:............ F3

Liquid Out: ......... F2

TABLE 2

TABLE 4

TABLE 3

1.

Be sure the entire system is clean

before starting operation to pre-

vent plugging of passages with debris.

The use of strainers or settling tanks in

pipelines leading to the heat exchanger

is recommended. The recommended

strainer size is 20-24 mesh.

Start operating gradually. See

Table 4 for suggested start-up

and shut-down procedures for most

applications. If in doubt, consult the

nearest ITT Heat Transfer representative

for specific instructions.

Do not operate the heat exchanger

under pressure and/or temperature

conditions in excess of the specified

design limits shown on the nameplate

attached to the heat exchanger.

Drain all fluids when shutting down

to eliminate possible freezing and

corroding.

2.

3.

4.

A heat exchanger is a pressure vessel designed for operation at certain specific limits of pressure and temperature. The cooling or process system,

which includes the heat exchanger, must be safeguarded with safety valves and controls so that these heat exchanger design conditions are not

exceeded. All operating personnel should be made aware of these specific design pressures and temperatures.

CAUTION:

Liquid

Hot

Liquid

Cold

Gas

Hot

Liquid

Cold

Condensing Gas

Hot

Liquid

Cold

Liquid or Gas

Hot

Vaporizing Liquid Cold

Condensers

REFRIGERATION:

STEAM TO LIQUID

Refrig. In:

F1

Refrig. Out:

F4

Liquid In:

F3

Liquid Out:

F2

Evaporators

Refrig. In:

F4

Refrig. Out:

F1

Liquid In:

F2

Liquid Out:

F3

Evaporators

Refrig. In: ......... F4

Refrig. Out: ...... F1

Liquid In:............ F2

Liquid Out: ......... F3

Condensers

Steam In:

F1

Condensate Out: F4

Liquid In:

F3

Liquid Out:

F2

STEAM TO LIQUID

Condensers

Steam In: ......... F1

Condensate Out: F4

Liquid In:............ F3

Liquid Out: ......... F2

Model

T (lbs)

F (lbs)

Mb (in-lbs)

Mv (in-lbs)

400

3327

1798.4 (-1348.8)

327.5

1504.6

410

411

5552.6

1798.4 (-1348.8)

540

1504.6

412

415

5552.6

2158.1 (-1663.5)

540

3407.5

422

24952.8

6069.6 (-4720.8)

6550

8912.7

433

Consult

Factory

Consult

Factory

Model

T (lbs)

F (lbs)

Mb (in-lbs)

Mv (in-lbs)

400

200

100

20

200

410

411

280

130

27

300

412

Start both fluids gradually

at the same time.

Start cold fluid

first then hot fluid.

Start hot fluid first then

slowly start cold fluid.

Avoid temperature shock.

Start hot fluid

first then cold fluid.

Shut down both fluids

gradually at the same time.

Shut down hot fluid

gradually then cold fluid.

Shut down cold fluid

first then hot fluid.

Shut down cold fluid

first then hot fluid.

Type of Fluid

Relative

Type of Fluid

Relative

Start-Up

Shut-Down

Temperature

Temperature

Procedure

Procedure

Condensers

REFRIGERATION:

Refrig. In: ......... F1

Refrig. Out: ...... F4

Liquid In:............ F3

Liquid Out: ......... F2

TABLE 2

TABLE 4

TABLE 3

435 psig Standard Design

Liquid

Hot

Liquid

Cold

Gas

Hot

Liquid

Cold

Condensing Gas

Hot

Liquid

Cold

Liquid or Gas

Hot

Vaporizing Liquid Cold

Condensers

REFRIGERATION:

STEAM TO LIQUID

Refrig. In:

F1

Refrig. Out:

F4

Liquid In:

F3

Liquid Out:

F2

Evaporators

Refrig. In:

F4

Refrig. Out:

F1

Liquid In:

F2

Liquid Out:

F3

Evaporators

Refrig. In: ......... F4

Refrig. Out: ...... F1

Liquid In:............ F2

Liquid Out: ......... F3

Condensers

Steam In:

F1

Condensate Out: F4

Liquid In:

F3

Liquid Out:

F2

STEAM TO LIQUID

Condensers

Steam In: ......... F1

Condensate Out: F4

Liquid In:............ F3

Liquid Out: ......... F2

Model

T (lbs)

F (lbs)

Mb (in-lbs)

Mv (in-lbs)

400

3327

1798.4 (-1348.8)

327.5

1504.6

410

411

5552.6

1798.4 (-1348.8)

540

1504.6

412

415

5552.6

2158.1 (-1663.5)

540

3407.5

422

24952.8

6069.6 (-4720.8)

6550

8912.7

433

Consult

Factory

Consult

Factory

Model

T (lbs)

F (lbs)

Mb (in-lbs)

Mv (in-lbs)

400

200

100

20

200

410

411

280

130

27

300

412

Start both fluids gradually

at the same time.

Start cold fluid

first then hot fluid.

Start hot fluid first then

slowly start cold fluid.

Avoid temperature shock.

Start hot fluid

first then cold fluid.

Shut down both fluids

gradually at the same time.

Shut down hot fluid

gradually then cold fluid.

Shut down cold fluid

first then hot fluid.

Shut down cold fluid

first then hot fluid.

Type of Fluid

Relative

Type of Fluid

Relative

Start-Up

Shut-Down

Temperature

Temperature

Procedure

Procedure

Condensers

REFRIGERATION:

Refrig. In: ......... F1

Refrig. Out: ...... F4

Liquid In:............ F3

Liquid Out: ......... F2

TABLE 2

TABLE 4

TABLE 3

150 psig Pressure Design

8.

The nozzle connections are designed

for normal torque force and damage

may occur if over tightened. The use of pipe

sealant materials compatible with the system

fluids is recommended for threaded type

connections. Connection load limits should be

observed and are shown in Figure 2, Table 2,

and Table 3.