Wind monitor-jr, Introduction, Initial checkout – Xylem H-375 04101 WIND MONITOR-JR User Manual

Page 2

Page 1

WIND SPEED SPECIFICATION SUMMARY

Range

0 to 60 m/s (130 mph), gust survival

100 m/s (220 mph)

Sensor

13 cm diameter 4-blade helicoid pro-

peller molded of polypropylene

Pitch

29.4 cm air passage per revolution

Distance Constant

2.0 m (6.6 ft.) for 63% recovery

Threshold Sensitivity

1.0 m/s (2.2 mph)

Transducer

Centrally mounted stationary coil, 2K

Ohm nominal DC resistance

Transducer Output

AC sine wave signal induced by

rotating magnet on propeller shaft.

40 mV p-p at 100 rpm. 4.0 V p-p

at 10,000 rpm.

Output Frequency

3 cycles per propeller revolution

(0.0980 m/s per Hz)

WIND DIRECTION (AZIMUTH) SPECIFICATION SUMMARY

Range

360° mechanical, 352° electrical

(8° open)

Sensor

Balanced vane, 21 cm (8 in)

turning radius.

Damping Ratio

0.3

Delay Distance

0.8 m (2.6 ft) for 50% recovery

Threshold Sensitivity

1.7 m/s (3.8 mph) at 10° displacement

Transducer

Precision conductive plastic poten-

tiometer, 10K ohm resistance (±20%),

1% linearity, life expectancy 50 mil-

lion revolutions, rated 1 watt at 40° C,

0 watts at 125° C

Transducer Excitation

Requirement

Regulated DC voltage, 15 VDC max

Transducer Output

Analog DC voltage proportional to

azimuth angle with regulated excita-

tion voltage applied across potenti-

ometer.

MODEL 04101

WIND MONITOR-JR

GENERAL

Operating Temperature

-50 to 50°C (-58 to 122 °F)

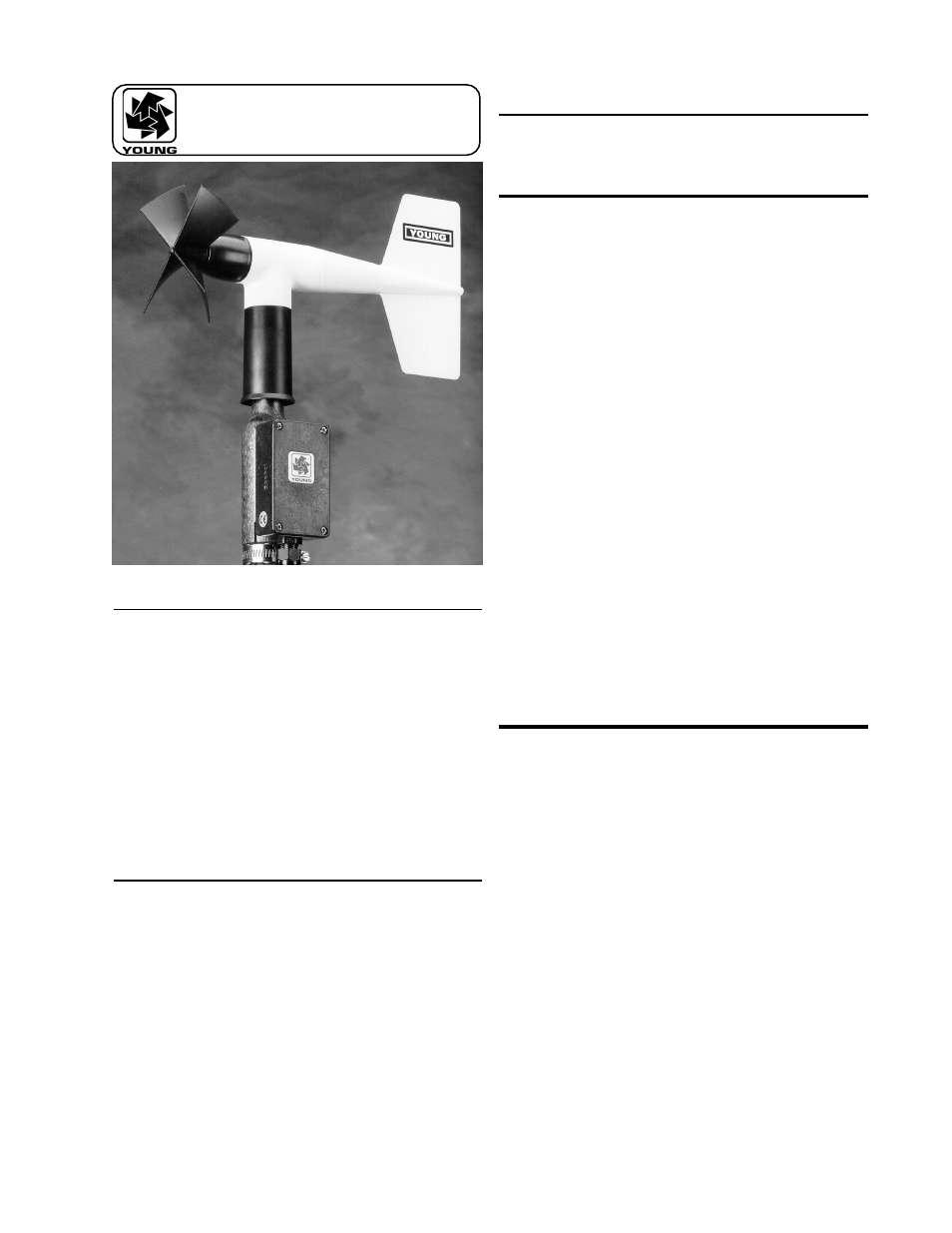

INTRODUCTION

The Wind Monitor measures horizontal wind speed and direction.

Originally developed for ocean data buoy use, it is rugged and

corrosion resistant yet accurate and light weight. The main

housing, nose cone, propeller, and other internal parts are

injection molded U.V. stabilized plastic. Both the propeller and

vertical shafts use stainless steel precision grade ball bearings.

Bearings have light contacting teflon seals and are filled with a

low torque wide temperature range grease to help exclude

contamination and moisture.

Propeller rotation produces an AC sine wave signal with fre-

quency proportional to wind speed. This AC signal is induced in

a stationary coil by a six pole magnet mounted on the propeller

shaft. Three complete sine wave cycles are produced for each

propeller revolution.

Vane position is transmitted by a 10K ohm precision conductive

plastic potentiometer which requires a regulated excitation

voltage. With a constant voltage applied to the potentiometer, the

output signal is an analog voltage directly proportional to wind

direction angle.

The instrument mounts on standard one inch pipe, outside

diameter 34 mm (1.34"). An orientation ring is provided so the

instrument can be removed for maintenance and reinstalled

without loss of wind direction reference. Both mounting post

assembly and orientation ring are secured to the mounting pipe

by stainless steel band clamps. Electrical connections are made

in a junction box at the base. A variety of devices are available

for signal conditioning, display, and recording of wind speed and

direction.

INITIAL CHECKOUT

When the Wind Monitor is unpacked it should be checked

carefully for any signs of shipping damage. The instrument is

aligned, balanced and fully calibrated before shipment, however

it should be checked both mechanically and electrically before

installation. The vane and propeller should easily rotate 360°

without friction. Check vane balance by holding the instrument

base so the vane surface is horizontal. It should have near

neutral torque without any particular tendency to rotate. A slight

imbalance will not degrade performance.

The potentiometer requires a stable DC excitation voltage. Do not

exceed 15 volts. When the potentiometer wiper is in the deadband

region, the output signal is “floating” and may show varying or

unpredictable values. To prevent false readings, signal condi-

tioning electronics should clamp the signal to excitation or

reference level when this occurs. Note: Young signal condi-

tioning devices clamp the signal to excitation level. Avoid

a short circuit between the wind direction signal line and either

the excitation or reference lines. Damage to the potentiometer

may occur if a short circuit condition exists.

Before installation, connect the instrument to an indicator as

shown in the wiring diagram and check for proper wind speed

and wind direction values. Position the vane over a sheet of

paper with 30° or 45° crossmarkings to check vane alignment.