Grout the baseplate, Piping checklist, Grout the baseplate piping checklist – Xylem AquaForce Variable Speed Package System User Manual

Page 16

Grout the baseplate

Required equipment:

• Cleaners: Do not use an oil-based cleaner because the grout will not bond to it. See

the instructions provided by the grout manufacturer.

• Grout: Non-shrink grout is required.

1. Clean all the areas of the baseplate that will come into contact with the grout.

2. Build a dam around the foundation.

3. Thoroughly wet the foundation that will come into contact with the grout.

4. Pour grout into the baseplate up to top of the base rails.

To hold wedges or shims in place, allow the grout to flow around them.

Follow grout manufacturer's instructions for removing air pockets from grout during

pour.

5. Allow the grout to set.

The grout needs to set for at least 48 hours. Follow any additional instructions from the

grout manufacturer.

6. Tighten the foundation bolts.

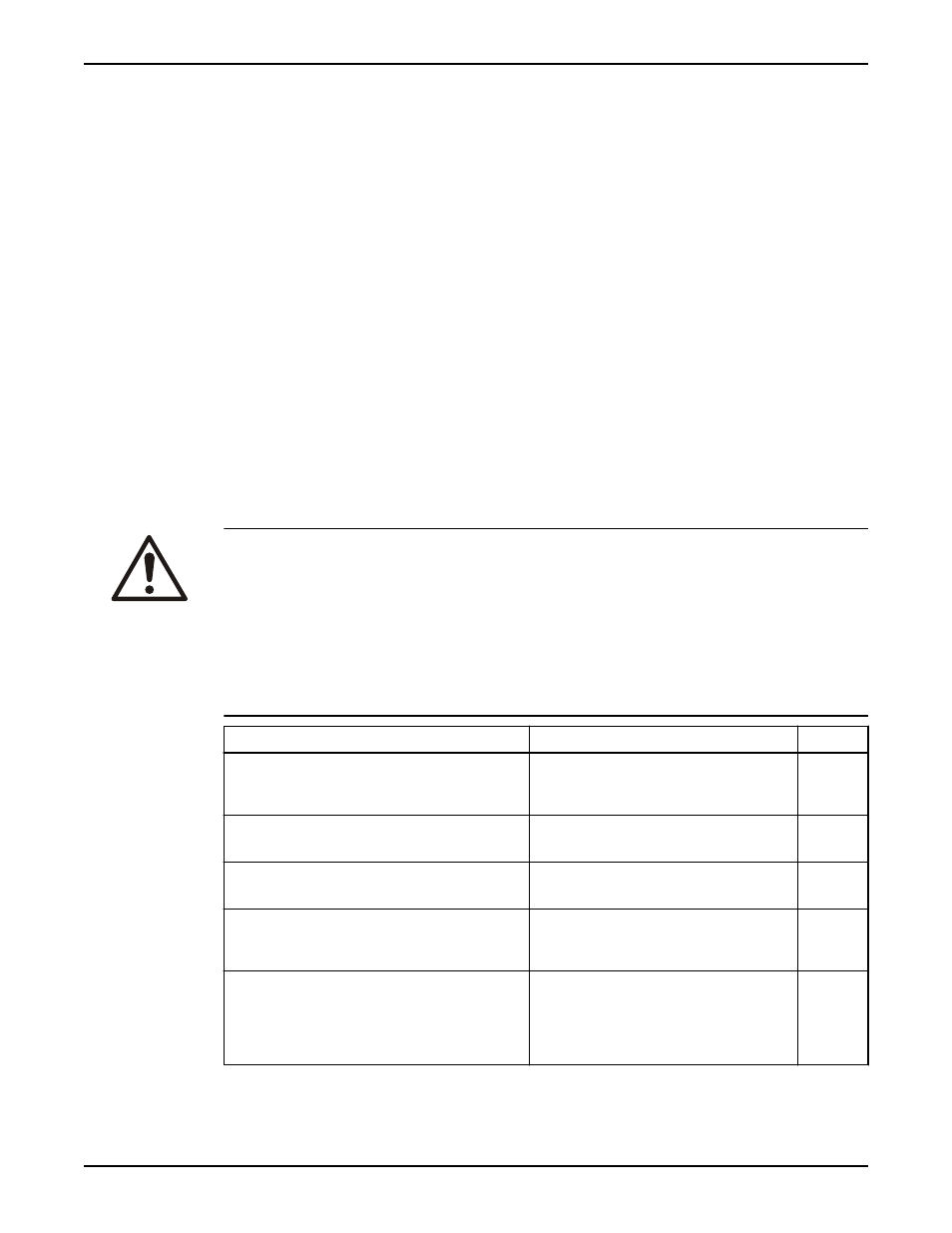

Piping checklist

WARNING:

• The heating of water and other fluids causes volumetric expansion. The associated forces

can cause the failure of system components and the release of high-temperature fluids.

In order to prevent this, install properly sized and located pressure-relief valves. Failure

to follow these instructions can result in serious personal injury or death, or property

damage.

• Avoid serious personal injury and property damage. Make sure that the flange bolts are

adequately torqued.

• Never force piping to make a connection with a pump.

Check

Explanation/comment

Checked

Check that the suction and discharge pipes are

supported independently by use of pipe hangers near

the pump station.

This eliminates pipe strain on the pump

station.

Check that there is a strong, rigid support for the

suction and discharge lines.

As a rule, ordinary wire or band hangers are not

adequate to maintain proper alignment.

Check that the suction or discharge lines are not

forced into position.

Component failure will result if suction or

discharge lines are forced into position.

Check that fittings for absorbing expansion are

installed in the system when considerable

temperature changes are expected.

This helps to avoid strain on the pump.

Check that you have a foot valve of equal or greater

area than the pump suction piping when you use an

open system with a suction lift.

Prevent clogging by using a strainer at the

suction inlet next to the foot valve. Make sure

that the strainer has an area three times that of

the suction pipe with a mesh hole diameter of

no less than 0.25 in. (0.64 cm).

Installation

14

AquaForce Variable Speed Package System Mechanical Installation, Operation, and Maintenance Manual