Xylem AC5659A G&L Pumps Series A-C 8100 Base Mounted Centrifugal Pumps User Manual

Page 27

27

Remove coupler guard (see separate instructions on page

29) and disconnect coupler.

Remove external tubing (1-939-9) if supplied.

2. Loosen but do not remove main joint capscrews (2-904-1

and 2-904-2). Insert a screwdriver or pry bar into the slots

between the upper and lower casing halves – separate

joint.

3. Remove all casing main joint capscrews and dowels

(2-916-1), lift off the upper casing half.

4. Tap the stuffing boxes with a soft-headed hammer to

break the seal between the stuffing box and lower casing

half, and lift the rotating element out of the lower casing.

NOTE: A spare rotating element can be installed at this

point (See Figure 26).

5. Remove four capscrews (3-904-9) from each bearing

housing (3-025-3 and 3-025-4) and remove the bearing

housings from the shaft.

6. Remove snap ring (3-915-4) (or locknut and lockwasher

on pumps built after 1991) from the outboard end of the

shaft and, using a puller, remove the bearing (3-026-4)

from the shaft. Remove the drive end bearing in the same

manner.

NOTE: Snap ring is not used on drive end bearing.

IMPORTANT: Do not reuse the ball bearings.

7. Slide stuffing boxes (3-073-9) off of the shaft, working

deflector ring (3-136-9) off the shaft at the same time (See

Photo 25).

8. Drive oil seal (3-177-9) from the stuffing box.

9. Remove the two gland bolts, gland halves and packing

from each stuffing box.

10. Remove two casing rings (3-003-9) from the impeller

(4-002-0) and remove “O” ring (3-914-2) and locating pin

(3-943-9) from each casing ring (See Photo 25).

11. Loosen set screw (3-902-3) in shaft nut (3-015-9) and

remove the nut. On pumps built after 1991, remove

O-rings from counterbore in shaft sleeves.

12. Remove shaft sleeve (3-009-9) and impeller (4-002-0).

NOTE: Apply heat uniformly to the shaft sleeve to loosen

the sealant between the shaft and sleeve. DO NOT HEAT

ABOVE 300°F. To further assist in removing the sleeve,

hold the shaft vertically and drop it on a block of wood.

The impeller weight should force both the impeller and

sleeve from the shaft.

CAUTION: Excessive Pressure Hazard

Make certain the internal pressure is relieved before

continuing. Failure to follow these instructions could result

in serious personal injury or death and property damage.

CAUTION: Extreme Temperature and/or

Flying Debris Hazard

Eye protection and gloves required. Failure to follow these

instructions could result in property damage and/or moder-

ate personal injury.

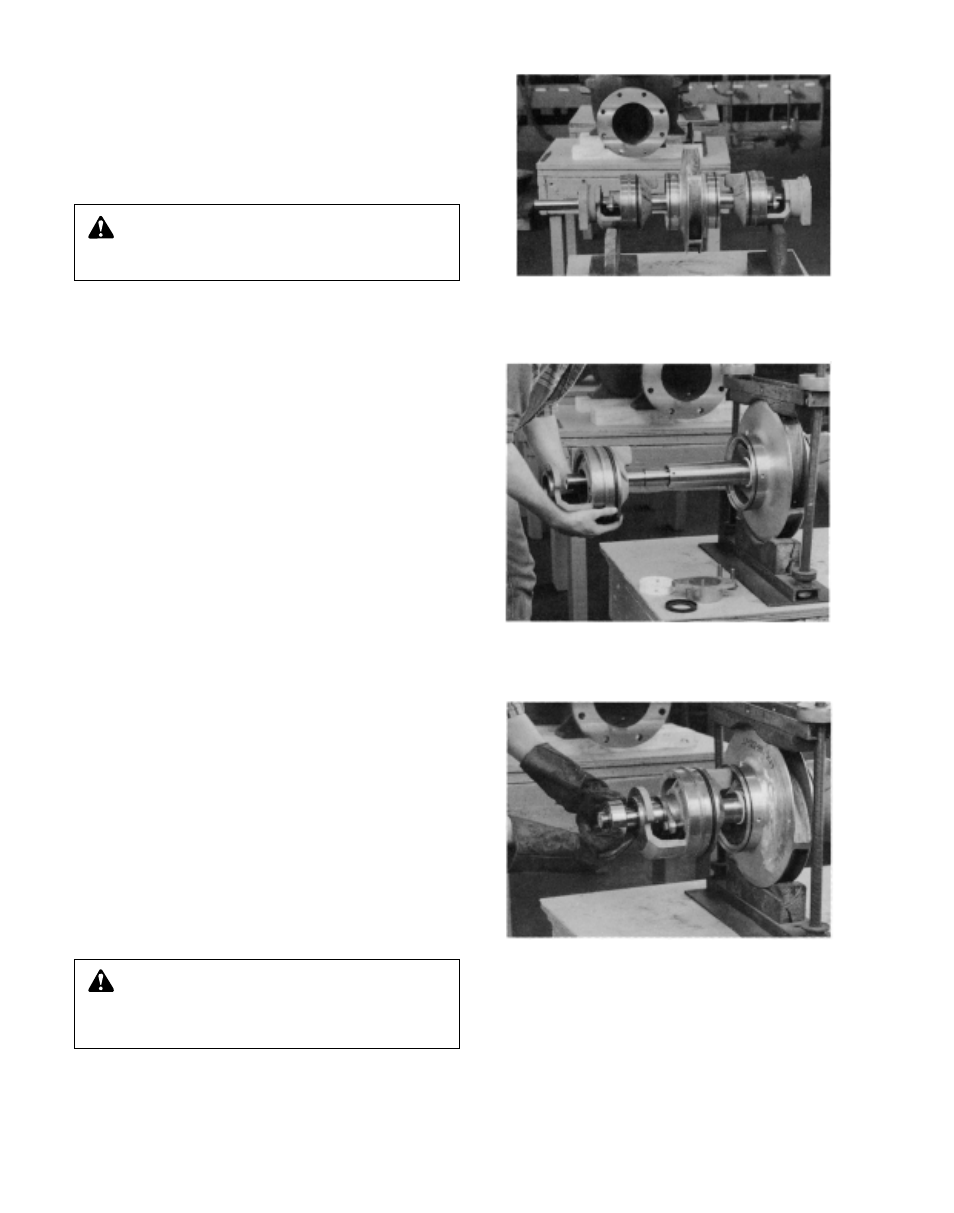

Photo 26 – Installing Shaft Bearing

Photo 24 – Rotating Element

(Packing Installed)

Photo 25 – Removing Stuffing Box