Piping checklist – Xylem 580-IM Marlow Series 580 User Manual

Page 14

Guideline

Explanation/comment

• Temperature controls

• Flow controls

If the system does not include these devices, consult the

engineer or architect in charge before you operate the

pump.

Take into consideration the occurrence of unwanted

noise and vibration.

The best pump location for noise and vibration

absorption is on a concrete floor with subsoil

underneath.

If the pump location is overhead, undertake special

precautions to reduce possible noise transmission.

Consider a consultation with a noise specialist.

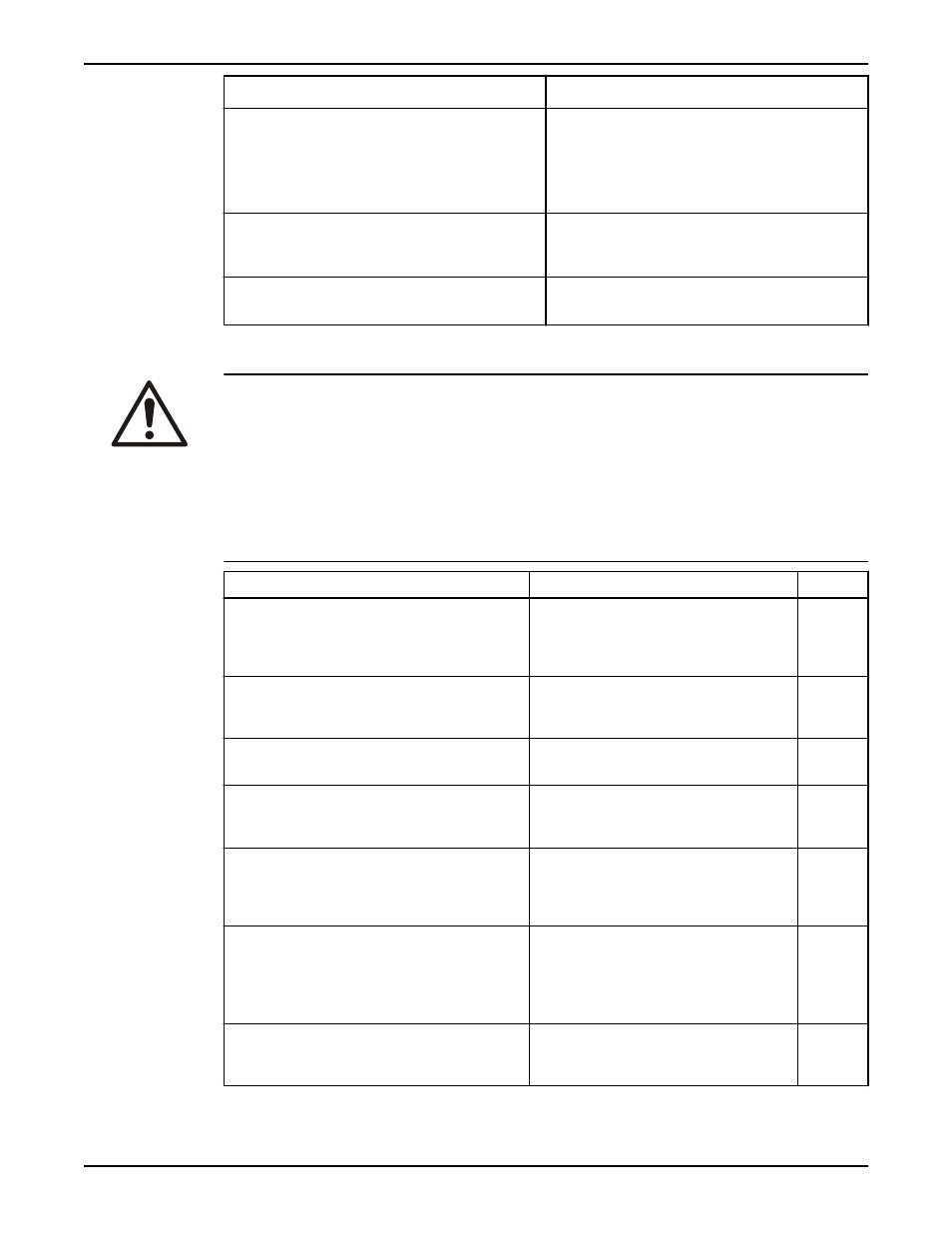

Piping checklist

WARNING:

• The heating of water and other fluids causes volumetric expansion. The associated forces

can cause the failure of system components and the release of high-temperature fluids.

In order to prevent this, install properly sized and located compression tanks and

pressure-relief valves. Failure to follow these instructions can result in serious personal

injury or death, or property damage.

• Avoid serious personal injury and property damage. Make sure that the flange bolts are

adequately torqued.

• Never force piping to make a connection with a pump.

Check

Explanation/comment

Checked

Check that a section of straight pipe, with a length that

is five times its diameter, is installed between the

suction side of the pump and the first elbow, or that a

suction diffuser is installed.

This reduces suction turbulence by

straightening the flow of liquid before it enters

the pump.

Check that the suction and discharge pipes are

supported independently by use of pipe hangers near

the pump .

This eliminates pipe strain on the pump .

Check that there is a strong, rigid support for the

suction and discharge lines.

As a rule, ordinary wire or band hangers are not

adequate to maintain proper alignment.

For pumps with flanges, check that the bolt holes in

the pump flanges match the bolt holes in the pipe

flanges.

—

For pumps mounted in vertical piping with the motor

in the horizontal position, check that adequate

support is provided.

This prevents strain on the pump parts and

piping. Do not mount the pump with the motor

vertically downward. Do not use motor lift rings

to suspend the pump.

Check that the suction or discharge lines are not

forced into position.

Coupling and bearing wear will result if suction

or discharge lines are forced into position.

The code for Pressure Piping (A.S.A.B. 31.1)

lists many types of supports available for

various applications.

Check that fittings for absorbing expansion are

installed in the system when considerable

temperature changes are expected.

This helps to avoid strain on the pump.

Installation

12

Series 580 Installation, Operation, and Maintenance Manual