Service instructions, Insulation – Bell & Gossett G95858H Circuit Setter Plus “RF” Balance Valves User Manual

Page 3

3

HOW TO USE THE MEMORY STOP FEATURE

1. Make the final degree of closure setting.

2. Loosen the memory stop locking screw in the slot on the top

of the adjustment knob.

3. Rotate the plastic ring under the adjustment knob counter-

clockwise until the tab on the plastic ring stops against the

nameplate.

4. Tighten the memory stop screw.

SERVICE INSTRUCTIONS

Periodically inspect the Circuit Setter for signs of leakage or

corrosion.

INSULATION

If an optional insulation set is used, then Bell & Gossett recom-

mends that the insulation be attached to the Circuit Setter after

the system has been balanced. Tape or other acceptable

means should be used to secure the insulation to the Circuit

Setter Balance Valve.

HOW TO USE THE BELL & GOSSETT

CIRCUIT SETTERS TO PROPORTIONATELY

BALANCE A SYSTEM

1. Open to “A” position all “RF” Circuit Setters and all standard

Circuit Setters to the fully open position for single pump

systems.

2. If more than one branch circuit is used, start the balance

procedure by reading all of the flows to the units in a branch.

Each unit (coil) should have its own Circuit Setter for flow

balancing. Using Bell & Gossett RP-250B readout probes,

sequentially attach a Bell & Gossett differential pressure

Readout Kit to the Readout Valves on each Circuit Setter

Balance Valve.

3. Using side 2 of the Bell & Gossett Circuit Setter Balance

Valve Calculator, with the top hairline set on zero for the size

Circuit Setter being read, or the pressure drop curves sup-

plied in this manual for the “RF” models read the flow cor-

responding to the pressure drop read with the readout kit.

4. Calculate the ratio of the actual flow to the design flow for

each unit in the branch. This is the proportional flow rate.

(Actual flow divided by design flow.)

5. Select the Circuit Setter with the lowest proportional flow.

This Circuit Setter is left in the “A” position if “RF” model or

the full open position for standard Circuit Setters. Every

other Circuit Setter in the branch is then reset to the same

proportional flow.

6. If there are additional branches, repeat the steps in 3 and 4

for each branch.

7. After all branches have been proportionately balanced,

measure the full open flows on the Circuit Setter Balance

Valves installed on the risers. Calculate the proportional

ratio of each riser Circuit Setter and select the one with the

lowest proportional ratio. This Circuit Setter is left fully open

and the other riser Circuit Setters are adjusted to the same

ratio.

8. Adjust pump flow so that circuits are receiving their design

flow. This can be accomplished by adjusting a Circuit

Setter Balance Valve installed on the pump discharge or by

changing the pump impeller size.

IMPORTANT:

If a high degree of throttling of flow at pump discharge is

required, Bell & Gossett recommends that the impeller be

sized to produce design flow. This will reduce electrical

energy consumption.

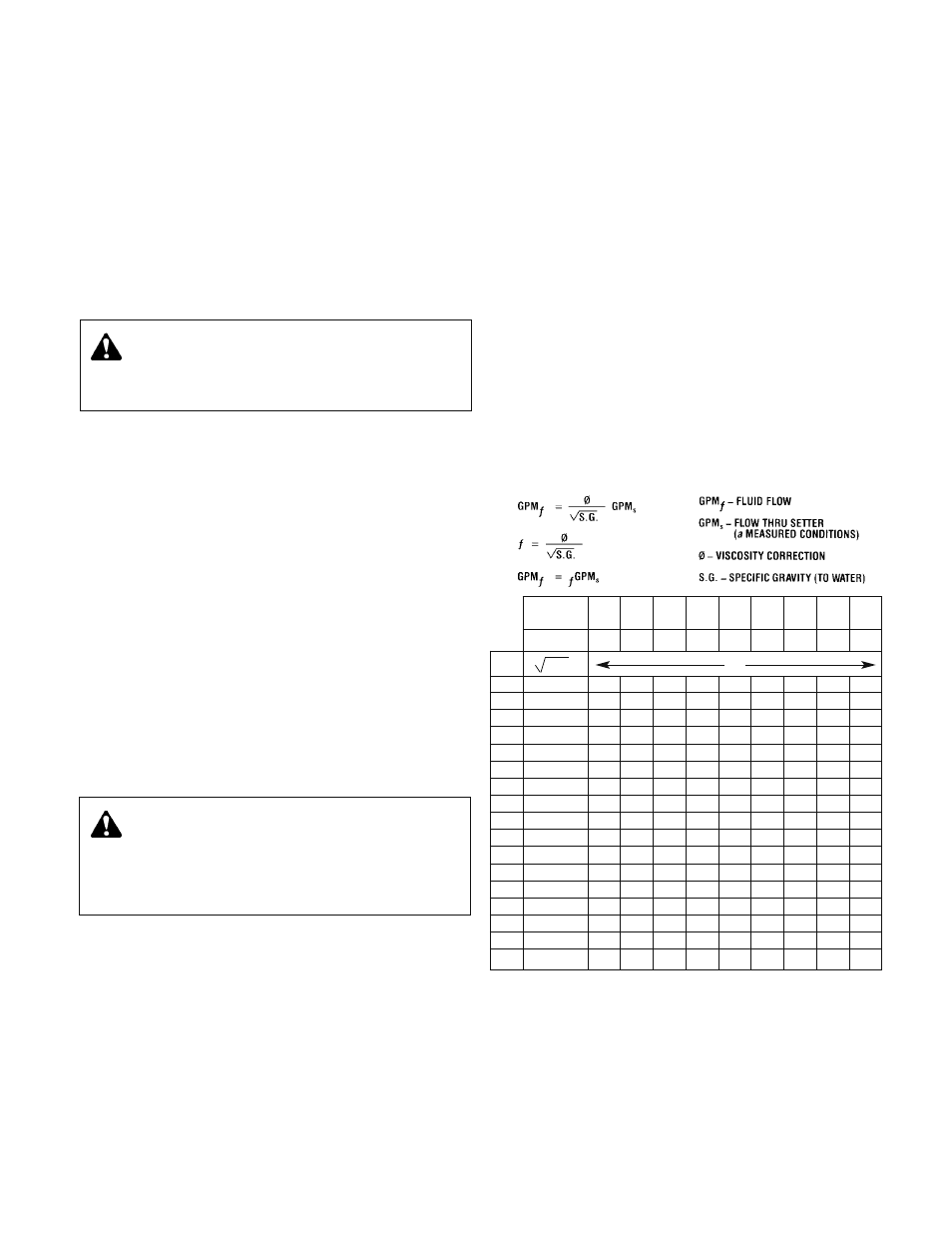

B&G CIRCUIT SETTER

CORRECTION FACTORS FOR

VISCOSITY AND SPECIFIC GRAVITY

WARNING: Corrosion or leakage are indications that

the Circuit Setter may be damaged and must be

replaced. Failure to follow this instruction could result in

serious personal injury and/or property damage.

WARNING: Hot water leakage can occur from

readout valves during probe insertion and during

hookup of readout kit. Follow the instruction manuals

supplied with readout probes and readout kits for safe use.

Failure to follow this instruction could result in serious per-

sonal injury and/or property damage.

VISCOSITY

CENTIPOISE

1

10

15

25

35

60

100

200

500

ø

1

.95

.90

.85

.80

.75

.70

.65

.60

S.G.

S.G.

ƒ

1

.60

.775

1.29

1.23

1.16

1.10

1.03

0.97

0.90

0.84

0.78

1

.65

.806

1.24

1.18

1.12

1.05

0.99

0.93

0.87

0.81

0.75

1

.70

.837

1.20

1.14

1.08

1.02

0.96

0.90

0.84

0.78

0.72

1

.75

.866

1.16

1.10

1.04

0.98

0.92

0.87

0.81

0.75

0.69

1

.80

.894

1.12

1.06

1.01

0.95

0.89

0.84

0.78

0.73

0.67

1

.85

.922

1.08

1.03

0.98

0.92

0.87

0.81

0.76

0.71

0.65

1

.90

.949

1.05

1.00

0.95

0.90

0.84

0.79

0.74

0.69

0.63

1

.95

.975

1.03

0.97

0.92

0.87

0.82

0.77

0.72

0.67

0.62

1.00

1.00

1.00

0.95

0.90

0.85

0.80

0.75

0.70

0.65

0.60

1.05

1.025

0.98

0.93

0.88

0.83

0.78

0.73

0.68

0.63

0.59

1.10

1.049

0.95

0.91

0.86

0.81

0.76

0.72

0.67

0.62

0.57

1.15

1.072

0.93

0.89

0.84

0.79

0.75

0.70

0.65

0.61

0.56

1.20

1.096

0.91

0.87

0.82

0.78

0.73

0.68

0.64

0.59

0.54

1.25

1.118

0.89

0.85

0.81

0.76

0.72

0.67

0.63

0.58

0.54

1.30

1.140

0.88

0.84

0.79

0.75

0.70

0.66

0.62

0.57

0.53

1.35

1.162

0.86

0.82

0.78

0.73

0.69

0.65

0.60

0.56

0.52

1.40

1.183

0.85

0.80

0.76

0.72

0.68

0.63

0.59

0.55

0.51